Slurry for micro-engine thrust chamber and preparation method and application of slurry

A thrust chamber and engine technology, which is applied to the slurry for the thrust chamber of a micro-small engine and its preparation and application fields, can solve the problem that the performance and life of the micro-small nozzle cannot meet the use requirements, the coating thickness is difficult, and the coating thickness is difficult. The coating on the throat of the nozzle is easy to accumulate and other problems, so as to achieve the effect of low cost, guaranteed coating thickness and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

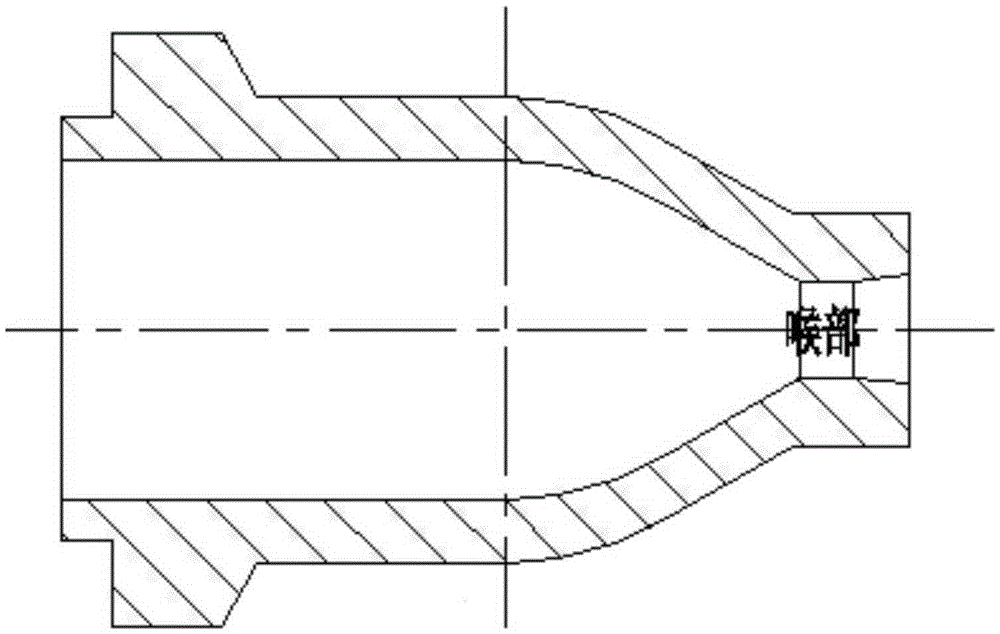

[0041] A kind of preparation method of thrust chamber of 1N two-component attitude orbit control engine, described thrust chamber nozzle comprises straight section, convergent section, throat and exit section, such as figure 1 shown;

[0042] The straight section is a hollow cylinder with a length of 4.2mm, an inner diameter of 3.2mm and an outer diameter of 4.4mm;

[0043] The converging section is a hollow circular platform with a length of 2.8mm, an inner diameter of the small end of 0.9mm, an outer diameter of the small end of 2.2mm, an inner diameter of the large end of 3.2mm, and an outer diameter of the large end of 4.4mm;

[0044] The throat is a hollow cylinder with a length of 0.5mm, an inner diameter of 0.9mm and an outer diameter of 2.2mm;

[0045] The outlet section is a hollow circular platform with a length of 0.5mm, an inner diameter of the small end of 0.9mm, an outer diameter of the small end of 2.2mm, an inner diameter of the large end of 1.04mm, and an out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thrust | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com