Dust Filter Baghouses for Power and Calcium Petrochemicals

A bag filter and dust filtration technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of poor wear resistance, short service life, easy to block bags, etc. Reasonable design, long service life and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

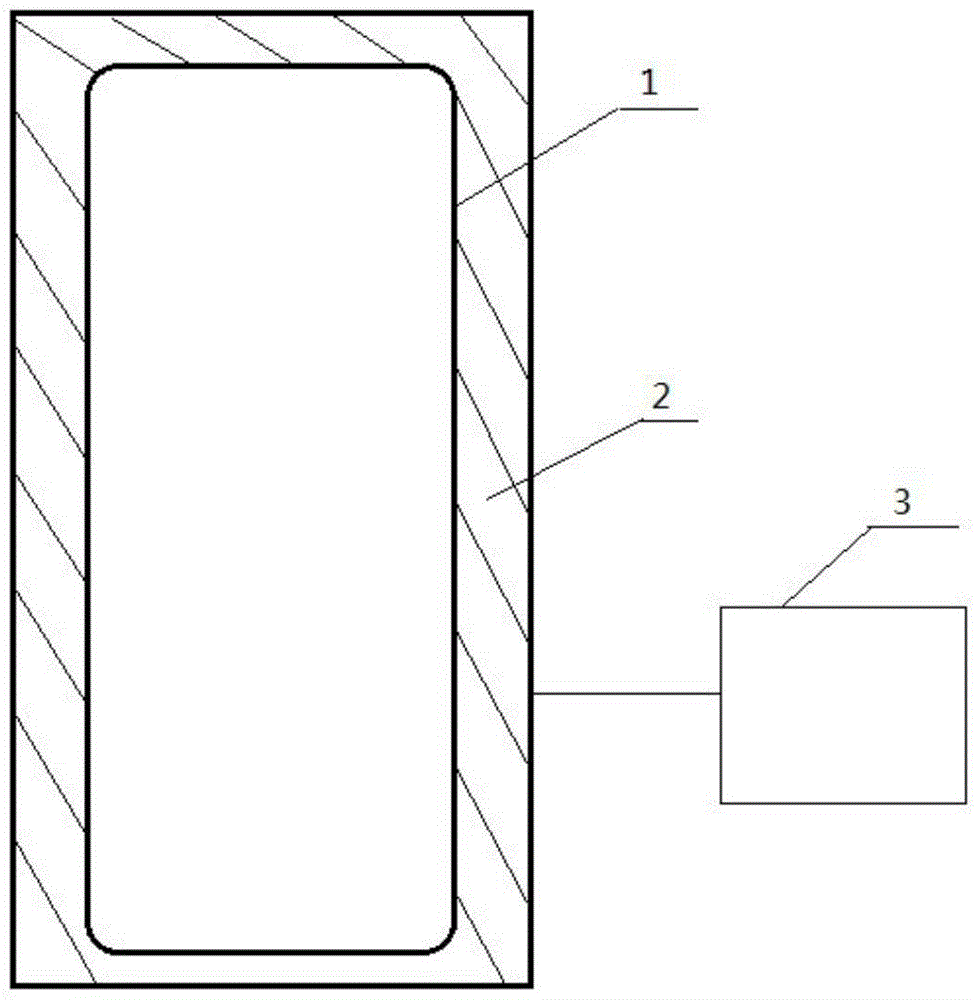

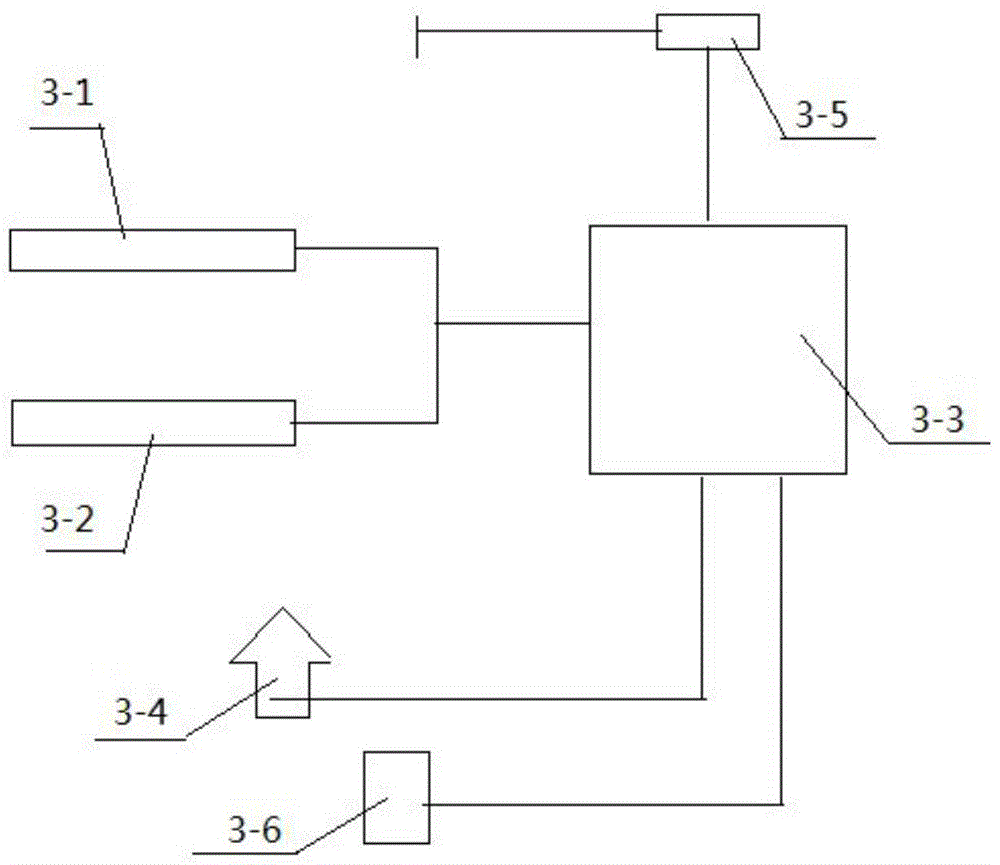

[0021] Such as Figure 1 to Figure 3 As shown, a dust filter bag filter for electric power and electric petrochemical industry, it includes a dust filter bag (1), a support frame (2) supported inside the dust filter bag (1), and a dust filter bag (1) connected control device (3); described control device (3) comprises temperature sensor (3-1), pressure sensor (3-2), and temperature sensor (3-1) and pressure sensor (3- 2) A connected controller (3-3), a blast device (3-4) connected to the controller (3-3), a vibrating device (3-5) and an alarm (3-6);

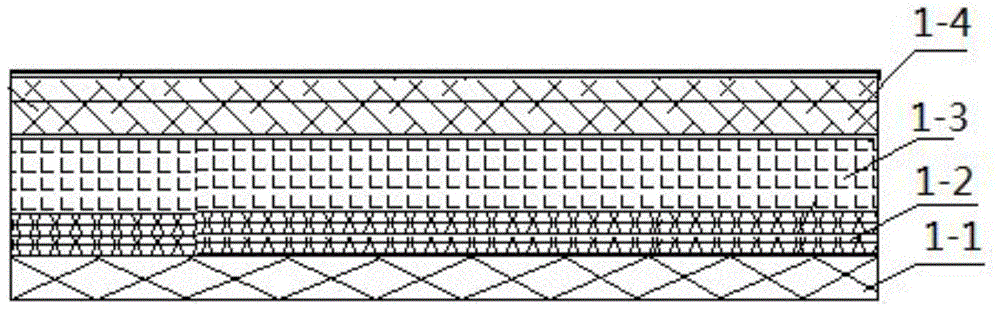

[0022] The dust filter bag (1) comprises a glass fiber needle felt inner surface layer (1-1), and a polyphenylene sulfide twill cloth (1-2) needle-punched on the glass fiber needle felt inner surface layer (1-1). ), needle-punched polytetrafluoroethylene fiber needle-punched felt (1-3) on polyphenylene sulfide twill (1-2), needle-punched on the upper surface of polytetrafluoroethylene fiber needle-punched felt (1-3) Glass fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com