An up-conversion light-emitting structure capable of increasing luminous intensity and its preparation method

A technology of luminous structure and luminous intensity, applied in luminescent materials, chemical instruments and methods, photovoltaic power generation, etc., can solve problems such as KLaF films that have not been seen, achieve regulation and enhancement, solve low luminous intensity, and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

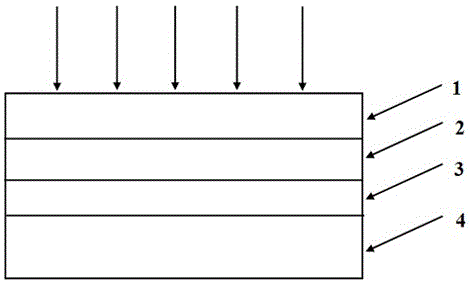

[0028] Example 1 Light emitting structure of Ag thin film / lanthanum potassium fluoride thin film without ZnO dielectric layer

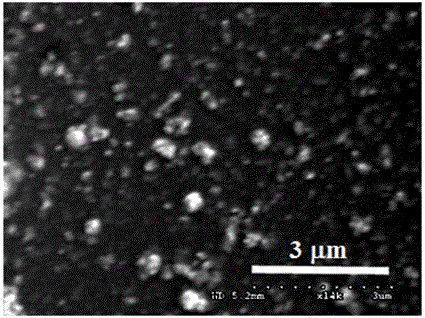

[0029] (1) Weigh 50 mg of polymethyl methacrylate (PMMA) powder and place it in a stirring bottle, then add 4 mL of chloroform solvent, stir for 30 minutes, then add 30-50 mg of aluminum-doped KLaF 4 : Yb 3+ / Er 3+ powder, continue stirring for 24 h to obtain a transparent colloidal solution;

[0030] (2) Clean the common glass substrate and dry it;

[0031] (3) Deposit a metal Ag film on the glass substrate by vacuum evaporation method, with a thickness of about 10-20 nm;

[0032] (4) The colloidal solution obtained in step (1) was spin-coated on the Ag film, and the spin-coating conditions were: forward rotation speed 650 rpm, time 12 s; back rotation speed 2000 rpm, time 30 s;

[0033] (5) After the film is dry, repeat the step (4) to obtain an up-conversion light-emitting layer with a thickness of 50-100 nm.

Embodiment 2

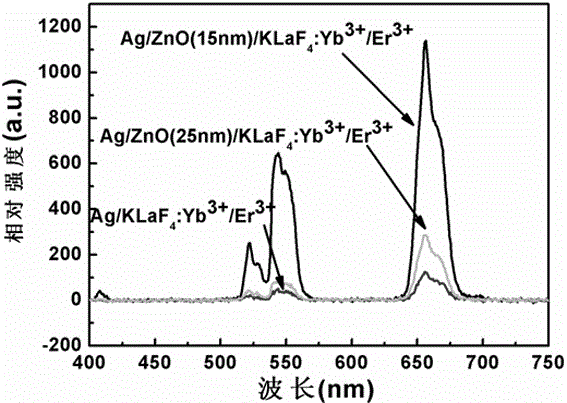

[0034] Example 2 Light emitting structure of Ag thin film / lanthanum potassium fluoride thin film containing ZnO dielectric layer

[0035] (1) Weigh 50 mg of polymethyl methacrylate (PMMA) powder and place it in a stirring bottle, then add 4 mL of chloroform solvent, stir for 30 minutes, then add 30-50 mg of aluminum-doped KLaF 4 : Yb 3+ / Er 3+ powder, continue stirring for 24 h to obtain a transparent colloidal solution;

[0036] (2) Clean the common glass substrate and dry it;

[0037] (3) Deposit a metal Ag film on the glass substrate by vacuum evaporation method, with a thickness of about 10-20 nm;

[0038] (4) Deposit zinc oxide on the metal Ag film by radio frequency magnetron sputtering. The sputtering process conditions are: use zinc oxide ceramic target, and the background vacuum is less than 6×10 -4 Pa, target base distance of 75 mm, Ar gas flow rate of 60 sccm, sputtering pressure of 0.5 Pa, sputtering power of 100 W, the obtained zinc oxide film thickness is 5-2...

Embodiment 3

[0042] Example 3 Light emitting structure of Au thin film / lanthanum potassium fluoride thin film without ZnO dielectric layer

[0043](1) Weigh 50 mg of polymethyl methacrylate (PMMA) powder and place it in a stirring bottle, then add 4 mL of chloroform solvent, stir for 30 minutes, then add 30-50 mg of aluminum-doped KLaF 4 : Yb 3+ / Er 3+ powder, continue stirring for 24 h to obtain a transparent colloidal solution;

[0044] (2) Clean the common glass substrate and dry it;

[0045] (3) Deposit a metal Au film on the glass substrate by vacuum evaporation method, with a thickness of about 10-20 nm;

[0046] (4) Spin-coat the colloidal solution obtained in step (1) on the Au film, the spin-coating conditions are: forward rotation speed 650 rpm, time 12 s; back rotation speed 2000 rpm, time 30 s;

[0047] (5) After the film is dry, repeat the step (4) to obtain an up-conversion light-emitting layer with a thickness of 50-100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com