Three-dimensional flow centrifugal blower with low-speed multistage vertical split cylinder structure

A ternary flow and blower technology, which is applied to pump components, mechanical equipment, radial flow pumps, etc., can solve the problems of unsmooth gas flow in corners, poor mechanical performance stability, and reduce the overall efficiency of the fan, so as to improve the efficiency of the fan. High efficiency, enhanced sealing effect, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

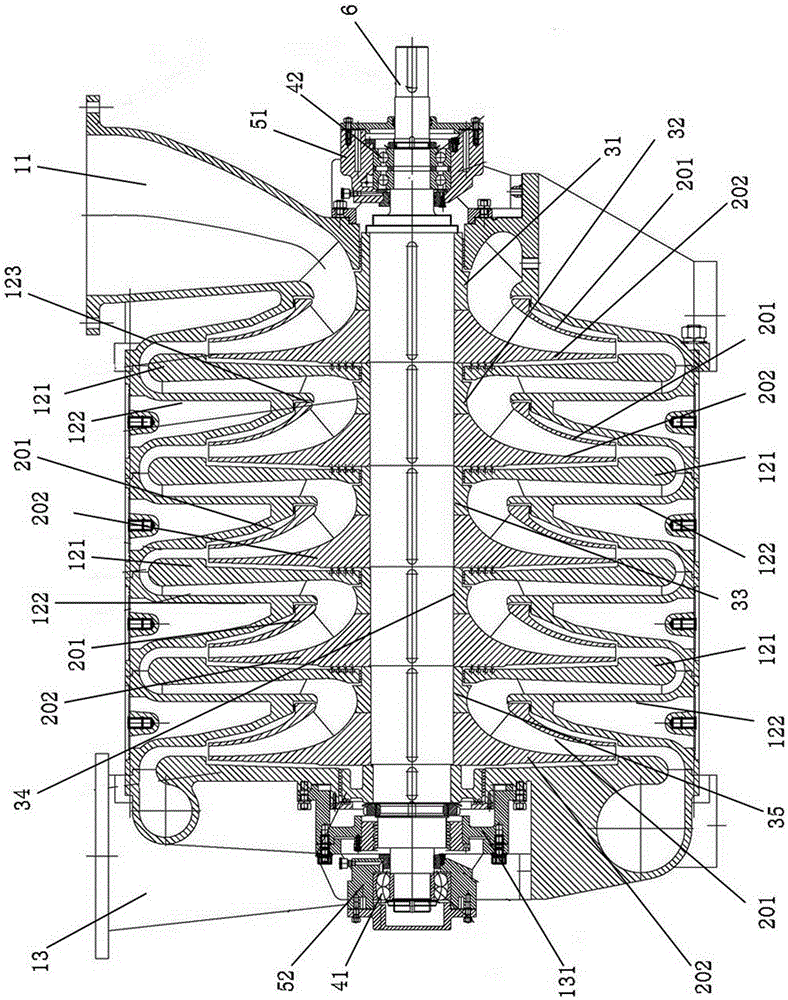

[0025] see figure 1 As shown, a three-dimensional flow centrifugal blower with a low-speed multi-stage vertical split cylindrical structure of the present invention is composed of a stator 1, a rotor 2, a bearing 4, a shaft seat 5 and a main shaft 6. The rotor 2 is located in the stator 1, and the two ends of the rotor 2 are respectively fixed by bearings 41, 42, and the two bearings 41, 42 are located in the bearing housings 51, 52.

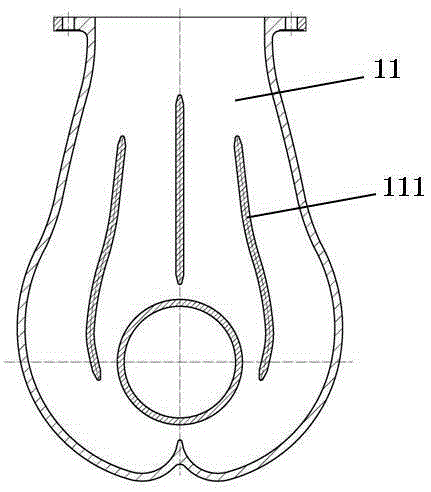

[0026] In the embodiment of the present invention, the rotor 2 is composed of five stages of independent impellers. The impeller (see figure 2 ), it adopts a closed three-dimensional flow structure, and the blades are three-dimensional streamlined. Based on computational fluid dynamics (CFD) technology, the flow channel of the gas in the blade is optimized to ensure the smooth flow of gas in the impeller. The aerodyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com