A hydraulic breaker

A technology of hydraulic breaker and hydraulic hammer, which is applied in earth mover/excavator, construction, etc. It can solve the problems of full hydraulic hammer and gas-liquid hammer with insufficient flow, powerless blow, large hydraulic impact, and difficulty in pressing down nitrogen blast hammer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

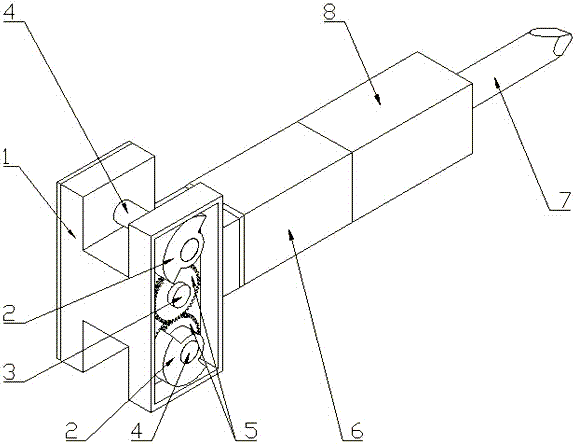

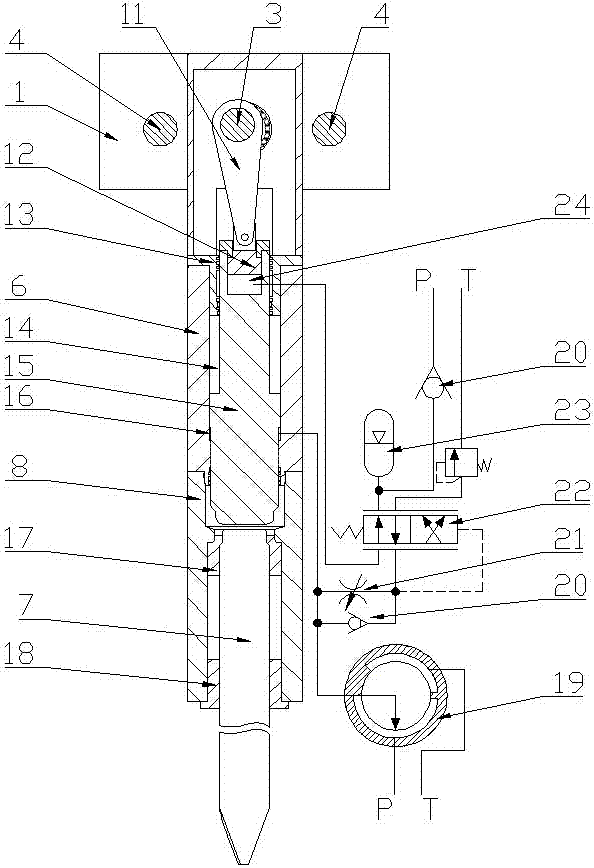

[0020] Main parts and components of the present invention:

[0021] 1. Crankcase 2. Eccentric wheel 3. Crankshaft 4. Eccentric wheel shaft 5. Gear 6. Cylinder block 7. Drilling rod 8. Drilling rod seat 11. Connecting rod 12. Connecting rod piston 13. Nitrogen chamber seal sleeve 14. Nitrogen chamber 15. Piston 16. Piston lower chamber 17. Drill rod rear sleeve 18. Drill rod front sleeve 19. Distribution plate 20. Check valve 21. Throttle valve 22. Reversing valve 23. Accumulator 24. Piston upper chamber.

[0022]At the moment of starting the hydraulic breaker, the piston 15 is at the farthest (dead point) from the crankshaft under the action of the nitrogen pressure in the nitrogen chamber 14. At this time, the piston lower chamber 16 and the hydraulic motor (used to drive the crankshaft 3 ) through high-pressure oil, under the action of the hydraulic motor through the crankshaft 3 connecting rod 11 and the high-pressure oil in the piston lower chamber 16, the piston 15 perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com