Axial flow mud pulse slow release device

A technology of mud pulse and slow release device, which is applied in the direction of flushing wellbore, wellbore/well components, pipes/pipe joints/fittings, etc. It can solve the problems of unsatisfactory slow release effect and difficult application of pulse damper, etc. Mud pulse, effect that reduces difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

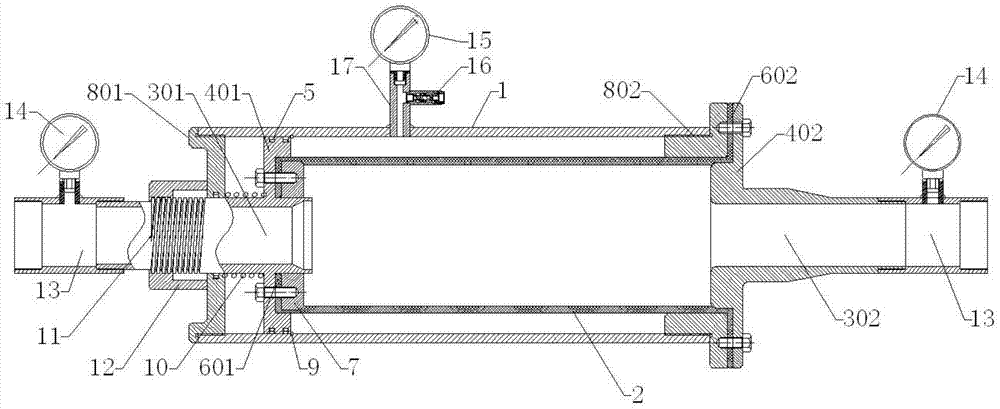

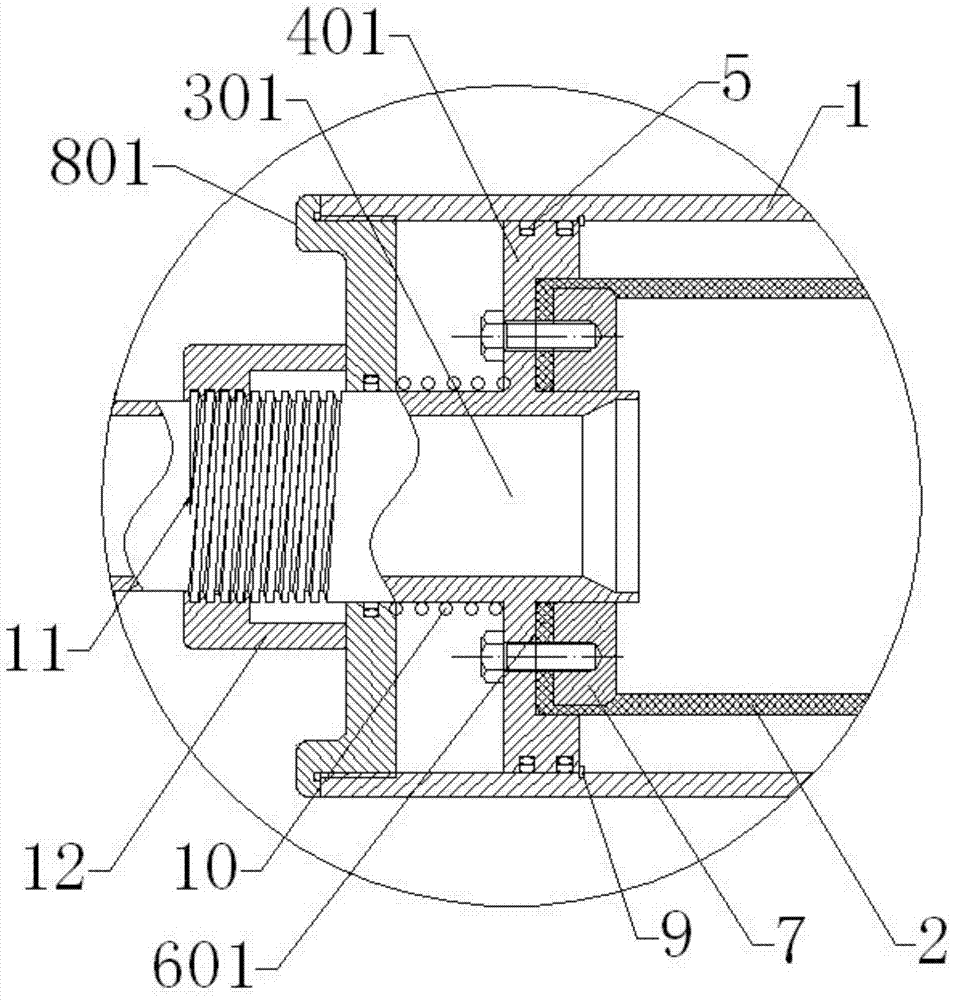

[0024] Below in conjunction with embodiment and its Figure 1-2 The present invention is described in further detail. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0025] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the axial flow mud pulse slow release device of the present invention.

[0026] An axial flow mud pulse slow release device, including a cavity filled with inert gas, the cavity includes an outer cylinder 1 and a rubber inner cylinder 2, and the two ends of the rubber inner cylinder 2 are respectively connected to a first outlet pipe 301 and a second outlet pipe 302 , the inner diameters of the first outlet pipe 301 and the second outlet pipe 302 are equal and smaller than the inner diameter of the rubber inner cylinder 2 . The pressure fluctuation and flow pulsation in the absorption pipeline are reduced by the large-diameter rubber inner cylinder 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com