A kind of high crystal density spheroidized NTO crystal and preparation method

A technology of crystal density and spheroidization, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems that NTO crystals cannot be directly applied, achieve mild reaction conditions, increase energy output, and use less solvent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention also provides a method for preparing the high crystal density spheroidized NTO crystal, the method comprising the following steps:

[0017] (1) Add NTO and solvent into the reactor for full dissolution, and the temperature of the reactor is 40-80°C;

[0018] (2) Lower the temperature of the reactor while stirring, and form a supersaturated solution to generate and grow crystal nuclei;

[0019] (3) After the crystals are completely precipitated, stir at a low temperature of -5-0°C for 1-5 hours;

[0020] (4) Filtration, drying and weighing.

[0021] The present invention has no special limitation on the heating method of the reactor, as long as it can play the role of heating the materials in the reactor. Preferably, a jacket can be provided outside the reactor, and hot water is introduced into the jacket for heating the reactor.

[0022] Preferably, the solvent in step (1) is at least one of absolute ethanol, dimethyl sulfoxide, nitrogen methylp...

Embodiment 1

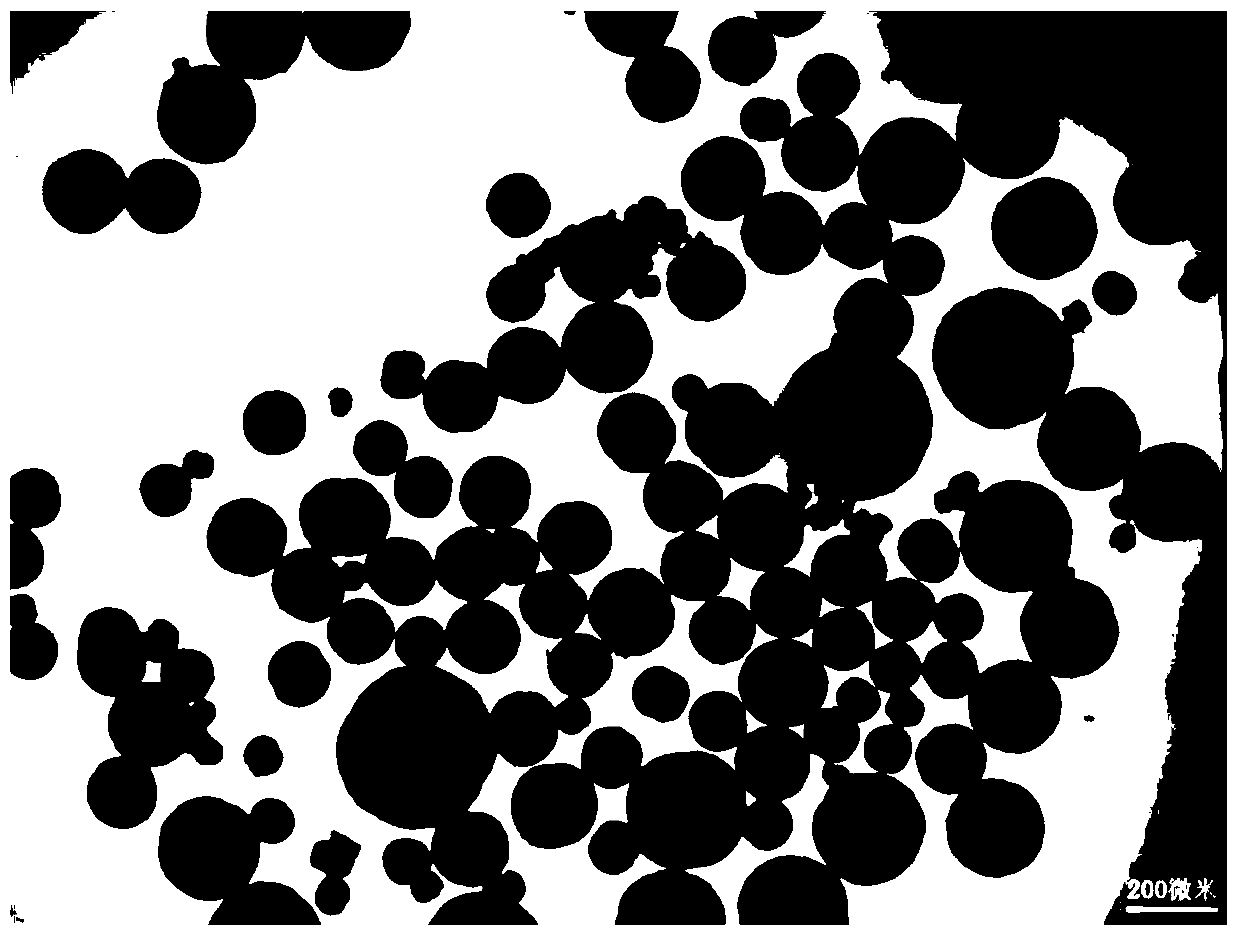

[0036] 500 g of NTO, 3 L of nitrogen methyl pyrrolidone and 7 L of absolute ethanol were added into a 20 L reactor, and the reactor was placed in a constant temperature water bath at 40°C. Turn on the stirrer, the stirring rate is 300rpm, and at the same time, control the cooling device to circulate the cooling liquid to the jacket of the reaction kettle, and the cooling rate is 5°C / min. When the temperature of the solution in the reaction kettle drops to 0°C, the cooling is stopped, and the temperature is kept and stirred for 2 hours. Filter, dry and weigh. The crystal weight is about 420 g, and the yield is 84%. According to the experimental determination, the NTO content is ≥99.9%, and the crystal density is 1.922g / cm 3 , the ratio of short and long axes of the crystal is 0.95; the median particle size of the crystal is 180 μm, and the particle size distribution is narrow. figure 1 It is an electron micrograph of the high crystal density spheroidized NTO crystal obtained...

Embodiment 2

[0038] Add 1000 g of NTO, 3.1 L of nitrogen methyl pyrrolidone and 9.3 L of distilled water into a 20 L reactor, which is placed in a constant temperature water bath at 50°C. Turn on the stirrer, the stirring rate is 200rpm, and at the same time, control the cooling device to circulate the cooling liquid to the jacket of the reaction kettle, and the cooling rate is 6°C / min. When the temperature of the solution in the reaction kettle drops to 0°C, the cooling is stopped, and the temperature is kept and stirred for 2 hours. Filter, dry and weigh. The crystal weight is about 780 g, and the yield is 78%. According to the experimental determination, the NTO content is ≥99.9%, and the crystal density is 1.92g / cm 3 , the ratio of the short and long axes of the crystal is 0.90; the median particle size of the crystal is 150 μm, and the particle size distribution is narrow. Appearance Observation The crystal has high sphericity, smooth surface and no cracks on the crystal plane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com