Isolation technology and process for extracting Ni and Co from nickel-containing high-cobalt hydroxide

A separation technology and oxide technology, which is applied in the separation technology and process field of extracting nickel and cobalt from nickel-containing high-cobalt hydroxide, can solve the problems of long process flow, high processing cost, and low direct metal recovery rate, and achieve Good separation effect, high leaching rate effect

Inactive Publication Date: 2016-01-27

JINCHUAN GROUP LIMITED

View PDF4 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The material usually contains high impurities such as Fe, Mn, Ca, Mg and Al, and conventional methods have the problems of long process flow, low direct metal recovery rate, high processing cost and poor operating environment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

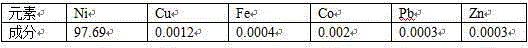

[0038] The raw material characteristic that the present invention adopts is shown in Table 1.

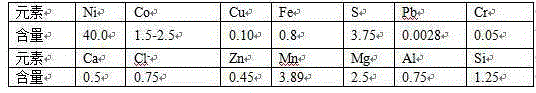

[0039] The production implementation result of the present invention is shown in Table 2,3.

[0040] Table 2 Leachate composition (g / l)

[0041]

[0042] Table 3 Leach residue composition (%)

[0043] .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

Login to View More

Abstract

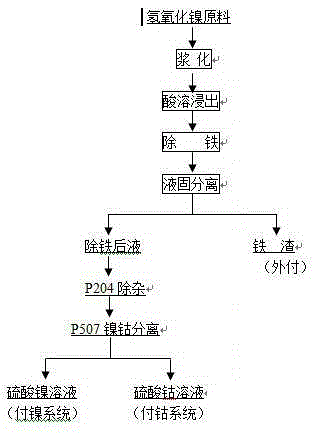

The sulfuric acid total leaching process is adopted in an isolation technology and process for extracting nickel and cobalt from nickel-containing high-cobalt hydroxide, so that a high Ni and Co leaching rate is guaranteed. By means of the processes of sulfuric acid leaching, impurity removal, extraction, and Ni-Co isolation, leaching agents rich in metallic nickel and metallic cobalt are obtained, the leaching agents are directly fed into an electro-deposited nickel and electro-deposited cobalt production system, and accordingly metallic nickel and metallic cobalt are isolated and extracted. The obtained leaching agents rich in metallic nickel and metallic cobalt can directly enter the electro-deposited nickel and electro-deposited cobalt production system. In addition, the process for extracting nickel and cobalt from nickel-containing high-cobalt hydroxide is simple, efficient, environment-friendly and suitable for treating nickel-containing high-cobalt hydroxide.

Description

Technical field [0001] A metallurgical technology that treats nickel -containing hypertrophic hydrogen oxides.Through the use of sulfuric acid immersion — removal -extraction — nickel -cobalt separation process for treatment, a sulfate solution with nickel -containing nickel is greater than 80g / L. This solution is produced by nickel production system to produce electrical nickel products;Sulfate solution, cobalt production system produces electrophoresis cobalt products. Background technique [0002] Jinchuan Group Co., Ltd. is my country's main nickel and cobalt production enterprises.In recent years, with the decrease in global nickel sulfide resources, the supply of nickel sulfide raw materials on the market has decreased year by year, and the purchase cost has gradually increased.In order to ensure the full load economy of the electric nickel production line and ensure the company's nickel capacity scale, the raw material structure must be adjusted -nickel hydroxide as supple...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B3/08C22B3/40C22B23/00

CPCY02P10/20

Inventor 耿文杰张军尤广宏周通丁才生杨永宁王瑞林魏秀兰李全赵丽萍吴玉明赵明郁

Owner JINCHUAN GROUP LIMITED

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com