Water-soluble protein peptide fertilizer

A protein peptide and soybean protein peptide technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of easy inactivation of enzymes, low enzyme activity, poor use effect, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

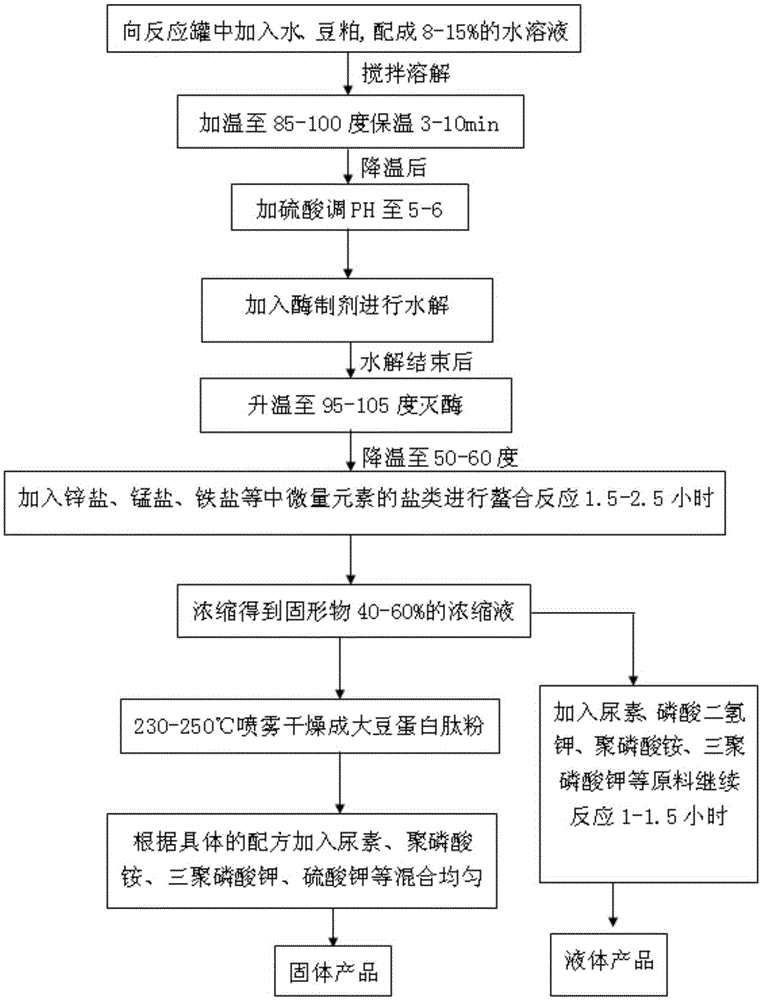

[0030] refer to figure 1 As shown, the present invention provides a protein peptide water-soluble fertilizer. The preparation method is as follows: A. Firstly, soybean meal is used as raw material and enzyme is added to prepare soybean protein peptide hydrolyzate. , manganese salts, iron salts, calcium salts, magnesium salts, or one or several trace element salts for chelation reaction, the reaction time is 1.5-2.5 hours, C. Concentrate the reaction product and concentrate it into 40-60 % concentrated solution, D, add one or more of urea, potassium dihydrogen phosphate, potassium sulfate, ammonium polyphosphate, potassium tripolyphosphate, potassium nitrate and continue to react at 50-60°C for 1-1.5 hours to obtain For liquid products, stir continuously during the reaction.

[0031] Adjust the content of microelements and macroelements according to the types of crops, the period of fertilizer application and the method of fertilization.

[0032] The preparation method of the...

Embodiment 2

[0035] The difference between this example and Example 1 is that the concentrated solution in step C is spray-dried at 230-250°C to form soybean protein peptide powder, and soybean protein peptide powder is added to the double-helix mixer , urea, potassium dihydrogen phosphate, potassium sulfate, ammonium polyphosphate, potassium tripolyphosphate, and potassium nitrate (select the type and adjust the addition amount according to the crop type, application period and application method), start stirring 5-10min, mix evenly to get a solid product.

Embodiment 3

[0037] Taking the protein peptide water-soluble fertilizer applied to the growth and development period of leafy vegetables as an example, in step B, 4% zinc salt and 5% iron salt are added by mass fraction, concentrated and then spray-dried to form soybean protein peptide powder. Add soybean protein peptide powder with a mass fraction of 58%, 36% urea, and 6% potassium dihydrogen phosphate into the double-helix mixer. During the reaction process, keep stirring to keep the temperature at 50-60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com