A kind of coordination type catalyst and the method for using the ethylene oligomerization of the catalyst to co-produce 1-hexene and 1-octene

An ethylene oligomerization and catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalyst, chemical instrument and method, physical/chemical process catalyst, etc., to achieve the effect of stabilizing the catalytic system and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

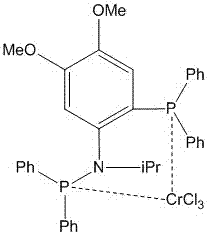

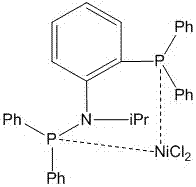

[0021] The method for co-producing 1-hexene and 1-octene by ethylene oligomerization is shown in the following formula, and the catalyst is used to catalyze ethylene oligomerization.

[0022]

[0023] The catalyst toluene solution of 1 mmol / L was freshly prepared in the glove box, and 10 mL of the catalyst solution was measured for use. Install the reaction kettle, preheat to 100°C, dry in vacuum and cool to room temperature, replace with ethylene atmosphere, add 50 mL of toluene solution, 10 mL of catalyst toluene solution, 1 mL of methylaluminoxane toluene solution (1.5 mol / L ), rapidly heated to 60 °C, while raising the ethylene pressure to 3 MPa, stirring at 800 rpm, and maintaining it for 60 min. Rapidly cool the reaction system to 0 °C, release the pressure, collect the gas with a gas trap, collect the solid polymer by filtration and weigh it dry, calculate the mass percentage separately, add 10 mL absolute ethanol and 1 mL 10% hydrochloric acid to the liquid Quenchi...

Embodiment 2

[0026] Change 60 DEG C of reaction temperature into 50 DEG C in embodiment 1, other operation conditions are constant, calculate and obtain catalyst activity by gas chromatography analysis and be 8.5 * 10 6 g / mol Cr h, the product composition is shown in Table 1, and the high polymer content is 0.82%.

Embodiment 3

[0028] Change 60 ℃ of reaction temperature into 40 ℃ among the embodiment 1, other operating conditions are constant, calculate and obtain catalyst activity by gas chromatographic analysis and be 7.8 * 10 6 g / mol Cr h, the product composition is shown in Table 1, and the high polymer content is 0.62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com