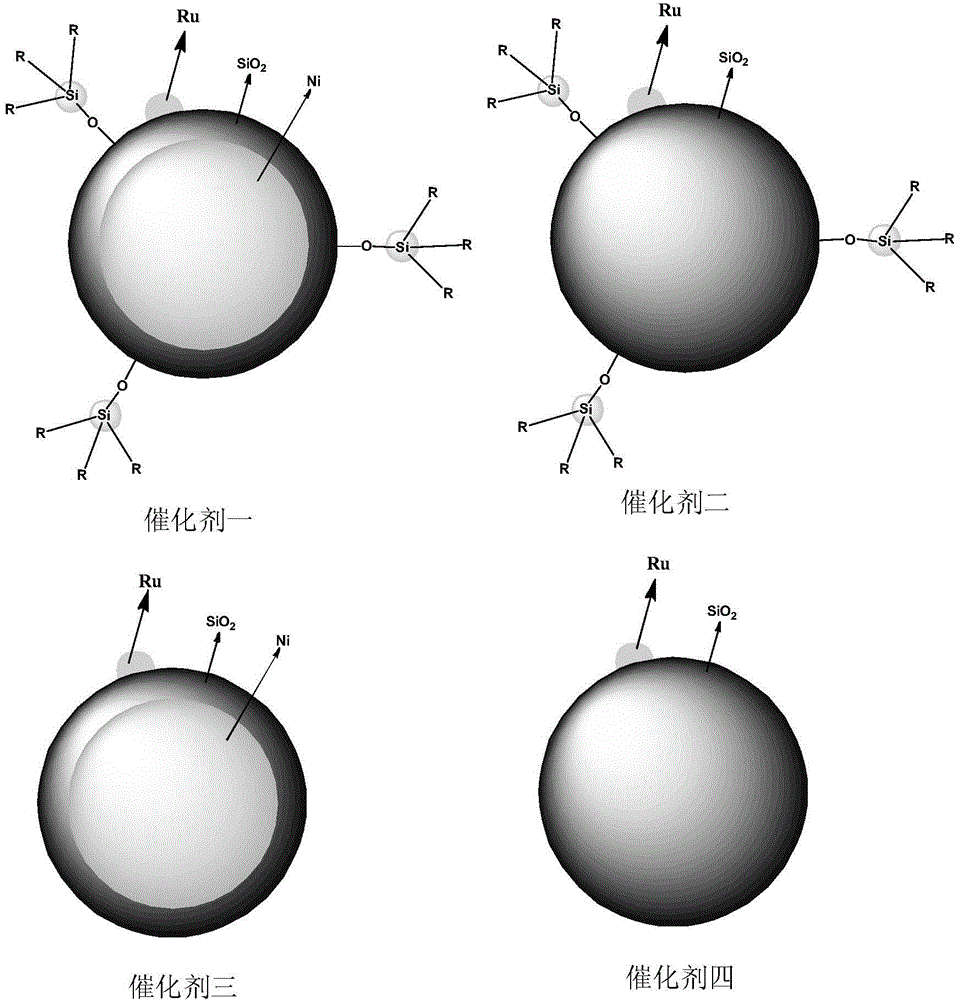

Silicon oxide-loaded ruthenium catalyst modified or unmodified with organic functional group and containing nickel or no nickel, and preparation method and application thereof

A technology of ruthenium catalyst and silica carrier, which is applied in the preparation of organic compounds, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of inability to achieve catalyst reaction activity, substrate universality, harsh reaction conditions, etc., and achieve good The effect of industrial application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] In a specific embodiment, the preparation method of the organic functional group modified nickel-containing silicon oxide supported ruthenium catalyst of the present invention comprises the following steps:

[0105] (1) Preparation of Ni-containing mesoporous silica:

[0106] Ni(NO 3 ) 2 ·6H 2 O was melted at 60-80°C for 0.5-2 hours, then added solvent ethanol and ground to a paste, and added dried silicon oxide into the paste and ground continuously until uniform, wherein the mass ratio of solvent ethanol to silicon oxide was 0.3~0.6:1. Calcining the obtained green powder at 350-550° C. for 1-4 hours to obtain Ni-containing mesoporous silicon oxide, wherein the mass percentage of nickel is 20-40 wt.%.

[0107] In the above steps, the solvent can also be a low-boiling-point solvent that can dissolve nickel salts such as methanol, isopropanol, and acetone.

[0108] (2) Preparation of nickel-containing silicon oxide nanoparticles wrapped by silicon oxide:

[0109] D...

Embodiment 1

[0118] 2.973g of Ni(NO 3 ) 2 ·6H 2 O was melted at 80°C for 1 hour, then 0.5ml of ethanol was added as a solvent and ground to a paste, and 1.4g of dried SBA-15 was added to the paste and ground continuously until uniform. The resulting green powder was calcined at 550°C in air for 2h. 1 g of the obtained nickel-containing SBA-15 was dispersed in 50 ml of water, 120 ml of ethanol was added to the mixed liquid, and 2 ml of 28% ammonia water was added dropwise. After stirring for 12 h, the collected carrier was filtered and dried at 120° C. for 4 h. Dissolve 0.5 g of dried nickel-containing SBA-15 coated with silicon oxide in anhydrous acetonitrile as a solvent, and after stirring to disperse evenly, add 0.38 ml of trimethylchlorosilane. Stirring was continued for 12 h, the turbid solution was filtered, and dried at 120° C. for 12 h. The resulting product was reduced with hydrogen at 400°C for 2 hours to obtain nickel-containing SBA-15 coated with silicon oxide. Weigh 0.29...

Embodiment 2

[0122] Catalyst preparation is the same as in Example 1.

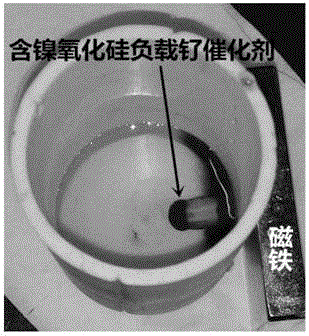

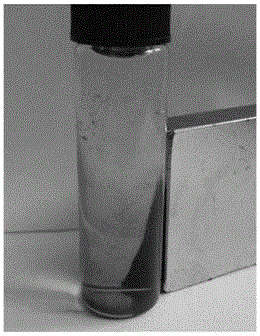

[0123] The prepared nickel-containing SBA-15 catalyst loaded with ruthenium, coated with silicon oxide and modified with methyl groups, is used for the liquid-phase hydrogenation catalytic reaction of levulinic acid. Take 20mg of the catalyst and put it into the autoclave, add 10ml of 0.25M levulinic acid aqueous solution, fill with 0.5MPa hydrogen, seal the autoclave, control the reaction temperature at 20°C, the speed at 600rpm, and react for 60min to obtain the target product 4-hydroxyvaleric acid, because 4-hydroxyvaleric acid is unstable at room temperature, placed at 80°C for 4 hours to obtain the product γ-valerolactone. The product analysis was carried out by gas chromatography, and the results are shown in Table 1. The steps of magnetic separation application are as follows: figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com