Testing apparatus for simulating marine engineering material under marine mud corrosion environment

A test device, corrosive environment technology, applied in measurement devices, analytical materials, weather resistance/light resistance/corrosion resistance, etc. Easy to operate, safe and easy to operate, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

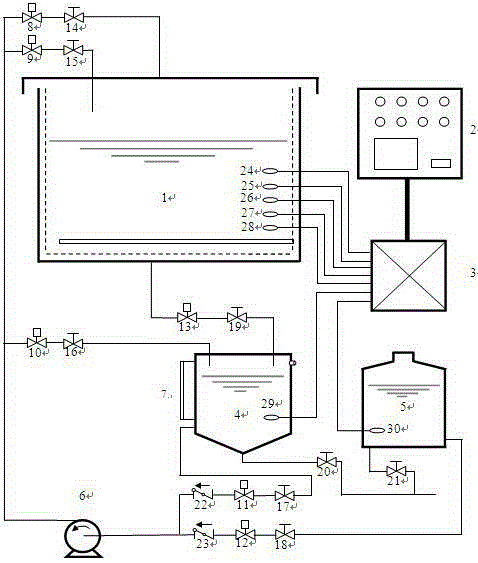

[0033] Example 1: Corrosion test of 45# steel sea mud coating under simulated natural conditions of ebb and flow.

[0034] Test sample: 45# steel;

[0035] Test medium: Shihai sea water, Shihai sea mud in Xiamen sea area;

[0036] Test conditions

[0037] a) Test temperature: 45°C;

[0038] b) Time interval between high tide and low tide: 6h;

[0039] c) Test medium replacement frequency: 7d;

[0040] d) Test time: 30 days;

[0041] Experimental procedure

[0042] a) close the seventh manual valve 20 and the eighth manual valve 21, and open the remaining manual valves;

[0043] b) Put real sea mud in the test chamber 1, and embed the test samples in parallel, and the test samples need to keep a certain distance;

[0044] c) fill up the real sea seawater in the circulating sedimentation tank 4 and the clean water tank 5;

[0045] d) Set parameters such as test temperature, time interval between rising and falling tides, and test liquid level;

[0046] e) Openin...

Embodiment 2

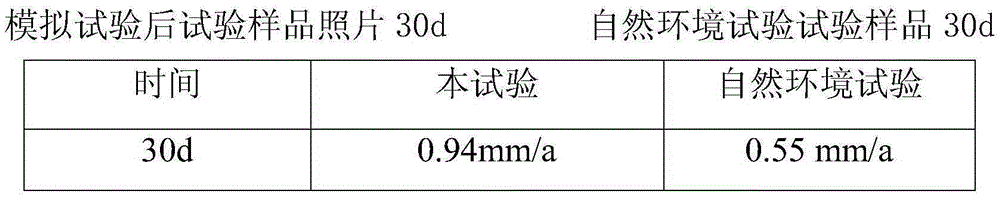

[0052] By the comparison of the above table, the test sample tested by this test device has a similar corrosion form with the test sample in the natural environment, and the difference in corrosion rate can reflect the influence of test parameters, and has a certain acceleration, which illustrates the present invention The test device is reliable in simulating the corrosion of natural sea mud environment and testing the corrosion resistance of metals, and provides a test platform for marine engineering material selection and evaluation. Embodiment 2: The overload protection test of the electric diaphragm pump.

[0053] Test sample: none;

[0054] Test medium: ordinary tap water;

[0055] Test conditions

[0056] a) Test temperature: room temperature;

[0057] b) Time interval between high tide and low tide: 2h;

[0058] Experimental procedure

[0059] a) close the first manual valve 14, the second manual valve 15, the seventh manual valve 20 and the eighth manual ...

Embodiment 3

[0065] Embodiment 3: Water replenishment operation test of the clean water tank.

[0066] Test sample: none

[0067] Test medium: ordinary tap water

[0068] Test conditions

[0069] a) Test temperature: room temperature;

[0070] b) Time interval between high tide and low tide: 2h;

[0071] Experimental procedure

[0072] a) close the seventh manual valve 20 and the eighth manual valve 21, and open the remaining manual valves;

[0073] b) Add half a box of ordinary tap water in the circulating sedimentation tank 4, and fill up the ordinary tap water in the clear water tank 5;

[0074] c) Set parameters such as test temperature, time interval between rising and falling tides, and test liquid level, and set the maximum value of test liquid level parameters;

[0075] d) Opening test: At this time, the fourth solenoid valve 11, the first solenoid valve 8 and the second battery valve 9 are opened simultaneously, the electric diaphragm pump 6 is started, and the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com