A current-carrying friction single contact peak arc testing machine

A current-carrying friction and single-contact technology, which is applied in the direction of testing wear resistance, etc., can solve the problem that the influence of arc heat on the wear performance of current-carrying friction pairs cannot be accurately measured, and achieve the effect of reducing resistance heat and overcoming mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

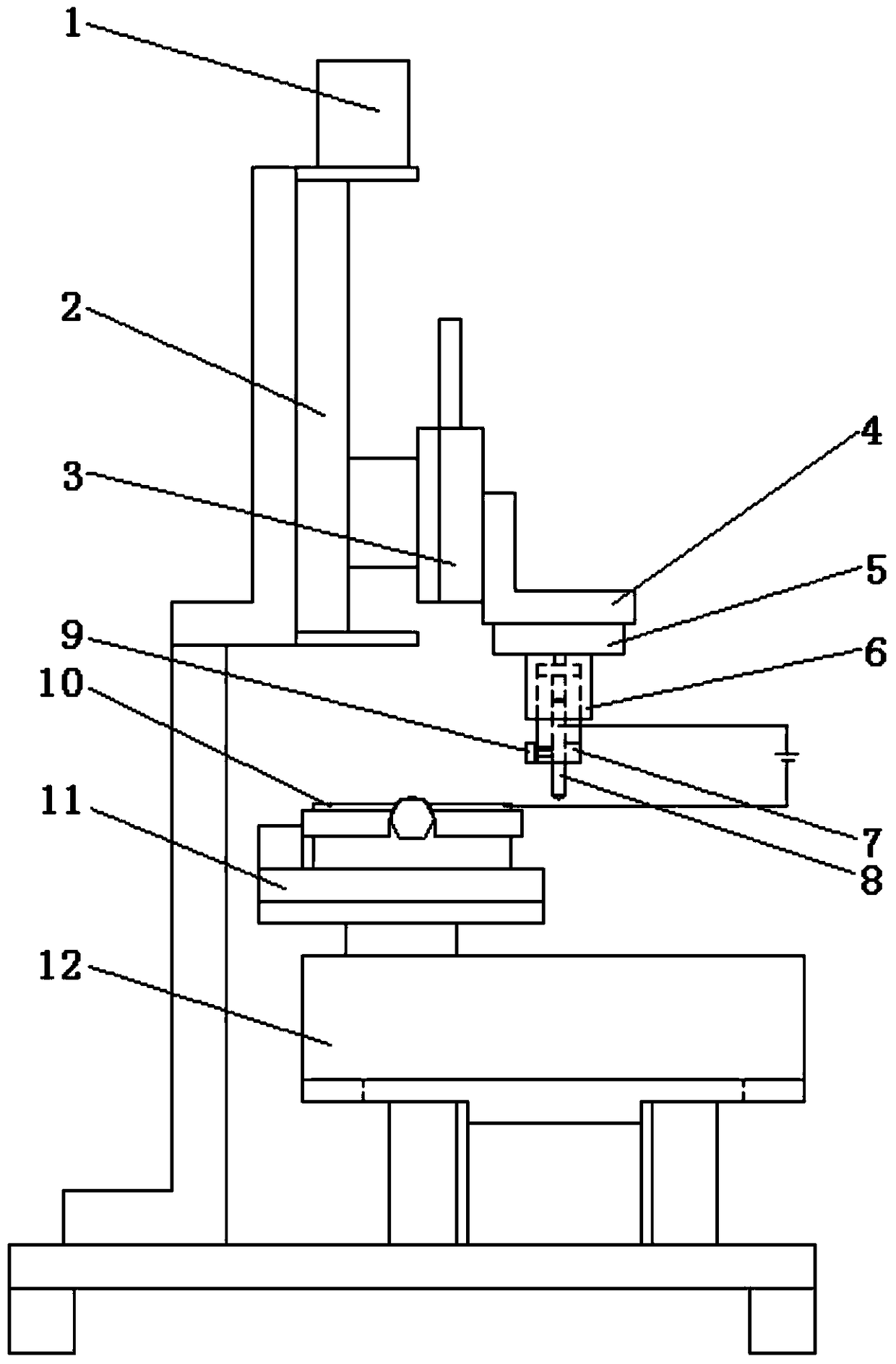

[0017] Such as figure 1 As shown, an embodiment of a current-carrying friction single-contact peak arc testing machine, the testing machine in this embodiment includes a frame 100, and the frame 100 is provided with a sample holder 11 for clamping a sample 10, where The sample holder 11 is specifically fixed on the mobile slide table 12 that can move linearly in a horizontal plane perpendicular to the up-down direction, and the mobile slide table 12 is driven by a linear drive mechanism to move linearly.

[0018] The frame 100 is also provided with an electrode spaced apart from the sample holder 11 in the vertical direction, which is used to load and press on the sample 10 and move relative to the sample 10 to form a current-carrying friction pair with the sample 10. 8. One end of the electrode 8 facing the sample holder 11 is a tip structure for forming point contact with the sample 10 .

[0019] In this embodiment, the electrode 8 and the sample holder 11 are arranged at i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com