A method for resourceful treatment and comprehensive recycling of electroplating sludge

A technology of electroplating sludge and recycling, which is applied in the direction of improving process efficiency, etc., can solve problems such as feasibility study reports and environmental impact assessment reports that are difficult for countries and governments to pass, affect the operating environment, consume oxidants, and achieve environmentally friendly production processes. The effect of short technological process and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

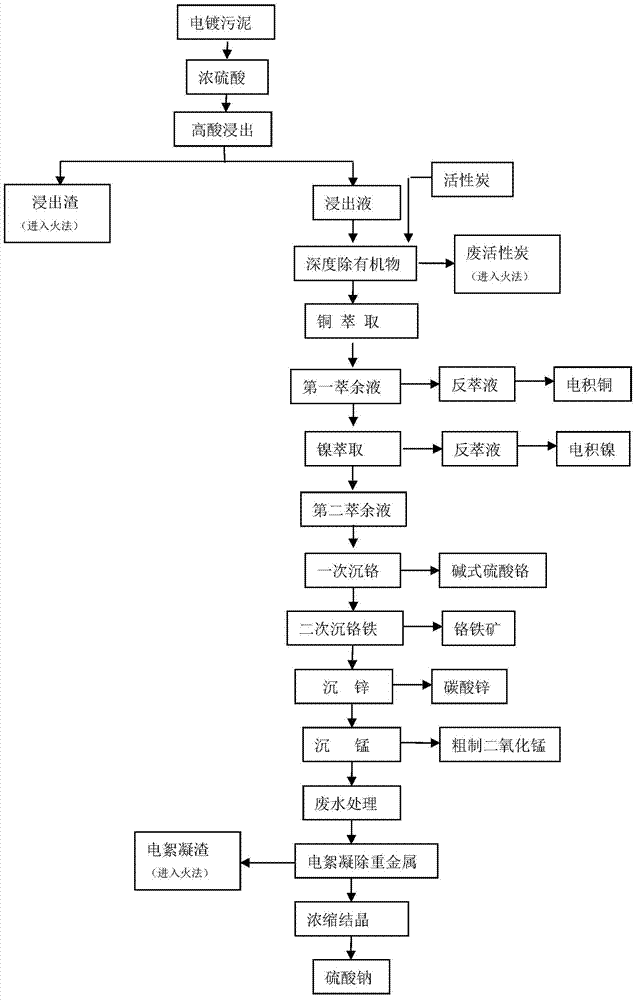

Image

Examples

Embodiment 1

[0048] A method for resourceful treatment and comprehensive recycling of electroplating sludge, comprising the following specific steps:

[0049] a) Pretreatment: Slurry, wash and screen 181.82kg of electroplating sludge first, then enter the super-thickener for thickening, press filter the underflow, and return the supernatant to slurry, wash and recycle. After the content of COD and other impurities in the washing water reaches 1000-3000mg / L, the special resin is used to remove COD, part of the washing water is recycled, and part of it enters the electrocoagulation wastewater treatment system for treatment to remove chlorine, nitrate, and trace heavy metals before being discharged up to standard. The expired resin and electric flocculation slag enter the pyrotechnic rotary drying kiln and then enter the high-temperature environmental protection reduction melting furnace for harmless disposal.

[0050] b) Acid leaching: add 27.27 kg of concentrated sulfuric acid with a mass c...

Embodiment 2

[0060] A method for resourceful treatment and comprehensive recycling of mixed materials such as electroplating sludge, chromium slag, copper-nickel sludge, etc., comprising the following specific steps:

[0061] a) Pretreatment: 9.69kg of electroplating sludge, chromium slag, copper-nickel sludge and other mixed materials are first slurried, washed and sieved, and the underscreen is filtered, and the filtrate is collected and mixed evenly. The impurity content is 200-250mg / L. Special resin is used to remove COD. Part of the washing water can be recycled, and part of it enters the electrocoagulation wastewater treatment system for treatment to remove chlorine, nitrate and trace heavy metals and then discharges up to the standard. The expired resin and electric flocculation slag enter the pyrotechnic rotary drying kiln and then enter the high-temperature environmental protection reduction melting furnace for harmless disposal.

[0062] b) Acid leaching: Add 1.36 kg of concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com