RH refining device

A refining device and ladle technology, applied in the field of RH refining production, can solve problems such as difficulty in increasing the circulating flow rate of molten steel, and achieve the effects of reducing the dead zone in the ladle, increasing the circulating flow rate, and increasing the circulating flow rate

Inactive Publication Date: 2016-01-20

SHANDONG IRON & STEEL CO LTD

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

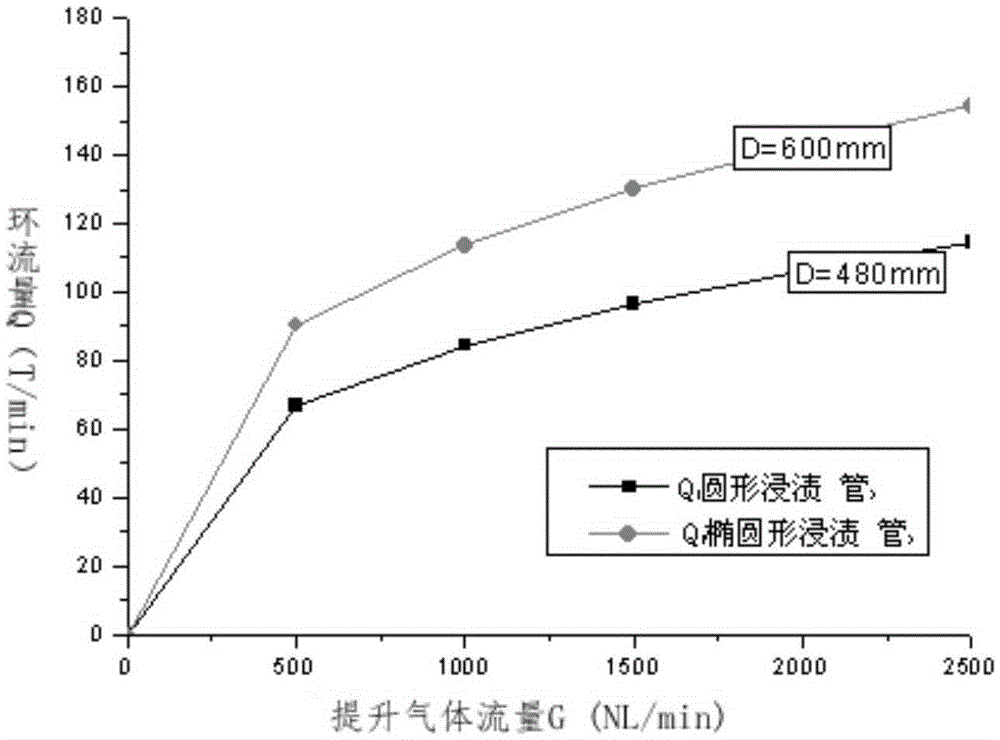

[0006] The object of the present invention is to provide a RH refining device, which improves the equivalent diameter of the RH dipping tube by changing the cross-sectional shape of the dipping tube, and fundamentally solves the problem that the circulating flow rate of molten steel is difficult to increase

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

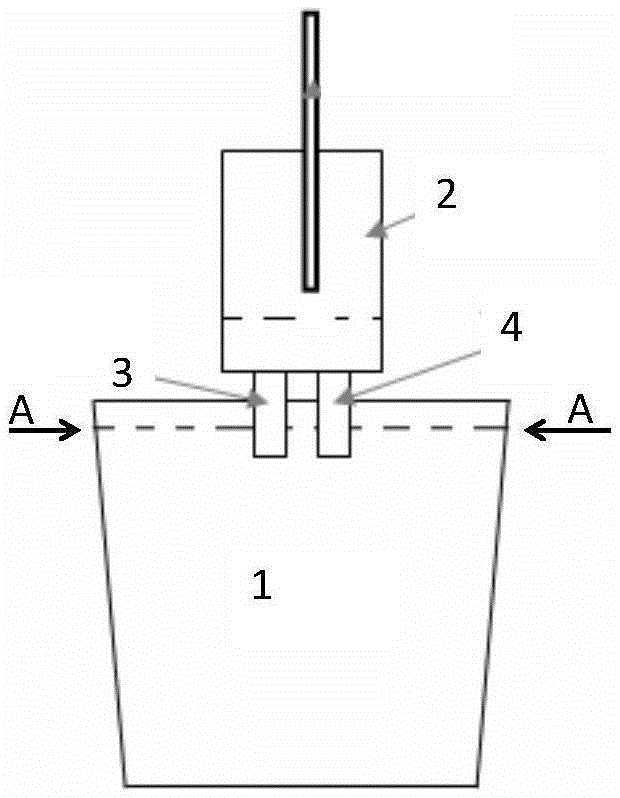

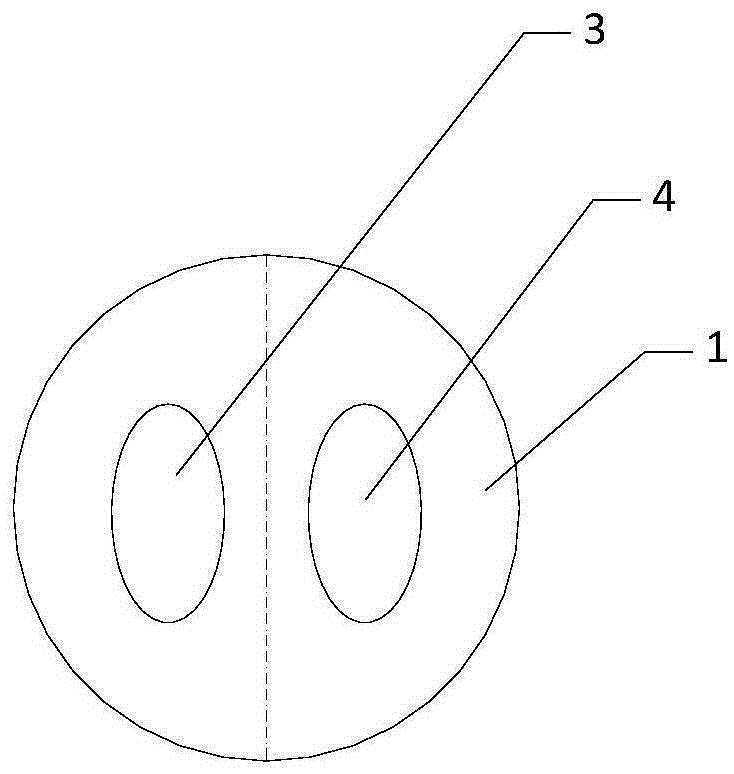

[0025] Such as figure 1 with figure 2 As shown, a RH refining device, the device includes a ladle 1 and a vacuum tank 2, and the ladle 1 and the vacuum tank 2 are communicated through a parallel rising dipping pipe 3 and a descending dipping pipe 4, characterized in that the The cross sections of the ascending dipping pipe 3 and the descending dipping pipe 4 are both elliptical.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a RH refining device which comprises a steel ladle (1) and a vacuum slot (2), wherein the steel ladle (1) and the vacuum slot (2) communicate through an ascending impregnation tube (3) and a descending impregnation tube (4) which are parallel; and cross sections of the ascending impregnation tube (3) and the descending impregnation tube (4) are oval. According to the device, by changing the shapes of the sections of the impregnation tubes, equivalent diameters of the RH impregnation tubes are increased, so that the problem that loop flow of molten steel is difficult to increase is radically solved.

Description

technical field [0001] The invention belongs to the field of RH refining production, in particular, the invention relates to an RH refining device. Background technique [0002] The RH refining process is named after the two German companies Ruhstahl and Heraeus that first developed this process. It is a secondary refining process for molten steel used to produce high-quality steel. The entire molten steel metallurgical reaction is carried out in a vacuum tank lined with refractory lining. The lower part of the vacuum tank is two dipping tubes with refractory lining, and the upper part is equipped with a hot bend. The gas flows from the hot bend and water-cooled bend to the vacuum pump system through the gas cooler. Before the molten steel is treated, the dipping tube is immersed in the ladle molten steel to be treated. When the vacuum tank is evacuated, the pressure difference between the atmospheric pressure on the surface of the molten steel and the pressure in the vacu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C7/10

Inventor 刘美倪培亮张学民张佩杨州韩杰

Owner SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com