Energy-saving apparatus used for catalytic synergy of natural gas

An energy-saving device, natural gas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve problems such as unsatisfactory stability, and achieve the effects of suppressing side reactions, improving energy efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

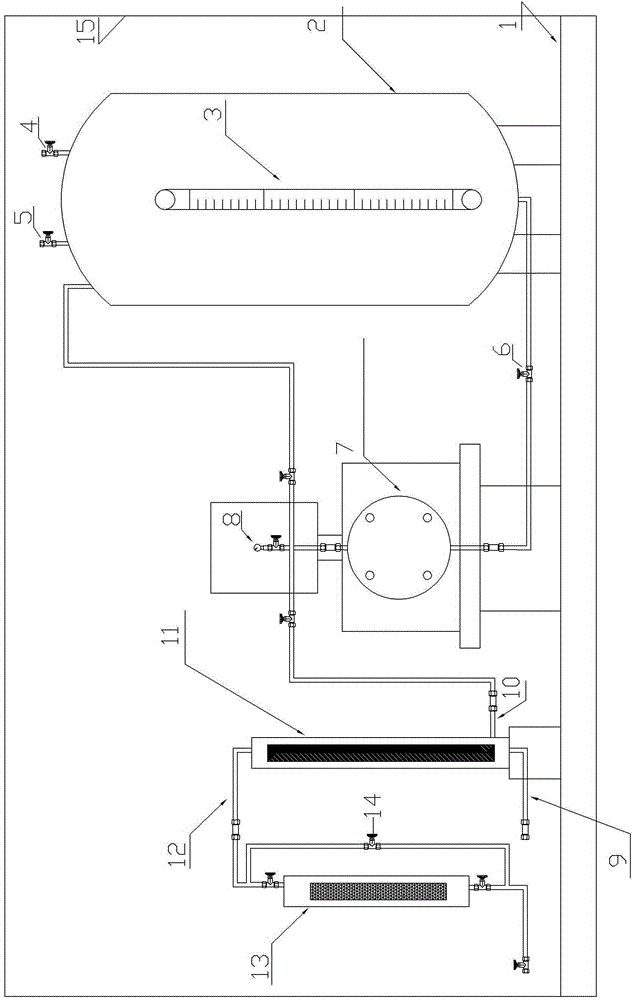

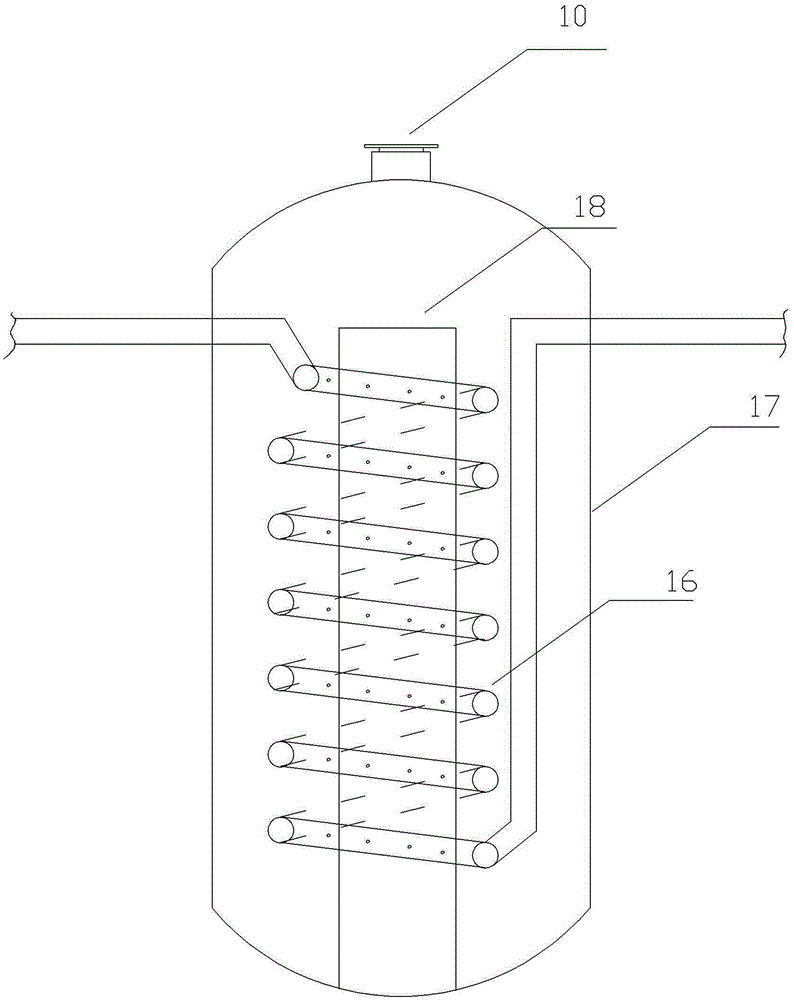

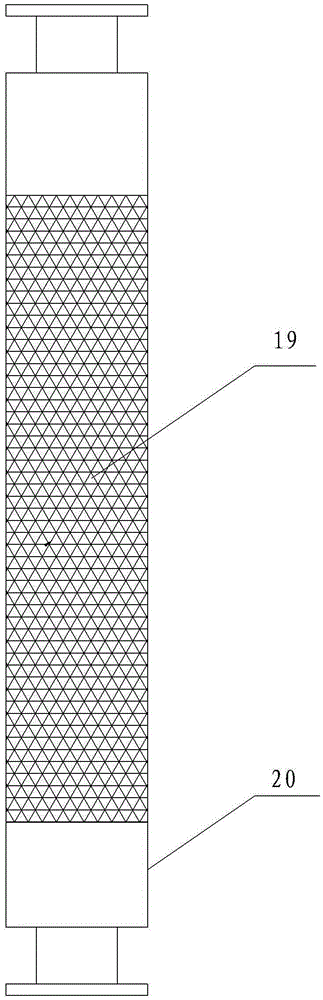

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the synergist includes the following steps.

[0053] 1) Nanoscale Ni and Cu-Zn alloy, Fe 3 o 4 、TiO 2 、AL 2 o 3 , SiO 2 Dissolve in No. 120 mineral spirits to obtain a mixed solution.

[0054] 2) Use an ultrasonic pulverizer to further disperse the components of the mixed solution, and then heat it to 40-45°C and stir, then add n-octyl ferrocene, heat it to 40-45°C again, and grind it with a grinder for 100- After 120 minutes, it is packed into galvanized packaging barrels.

Embodiment 1

[0056] The energy-saving additive for natural gas combustion comprises the following components in parts by weight.

[0057] n-octyl ferrocene 2g

[0058] Nanoscale Ni and Cu-Zn alloy 2g

[0059] Fe 3 o 4 3g

[0060] TiO 2 3g

[0061] AL 2 o 3 3g

[0062] SiO 2 0.5g

[0063] No. 120 mineral spirits 45g.

Embodiment 2

[0065] The energy-saving additive for natural gas combustion includes the following components in parts by weight.

[0066] n-octyl ferrocene 4g

[0067] Nanoscale Ni and Cu-Zn alloy 4g

[0068] Fe 3 o 4 6g

[0069] TiO 2 6g

[0070] AL 2 o 3 6g

[0071] SiO 2 2g

[0072] Isopropanol 5g

[0073] No. 6 solvent naphtha 55g.

[0074] A kind of efficiency-enhancing and energy-saving additive for improving the combustion efficiency of natural gas and its preparation method, comprising the following steps: nano-scale material Ni and Cu-Zn alloy, Fe 3 o 4 、TiO 2 、AL 2 o 3 , SiO 2 1. Dissolve isopropanol in No. 6 solvent oil and use an ultrasonic pulverizer to further disperse the nano-metal material. After heating to 40-45°C and stirring, add n-octyl ferrocene, and heat again to 40-45°C , Grind with a grinder for 100-120 minutes, then pack into special galvanized packaging barrels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com