Purification salt conversion method of micafungin

A micafungin and salt conversion technology, which is applied in the field of medicinal chemistry, can solve the problems of easy hydrolysis, unfavorable product quality control, and unfavorable industrial scale-up production, etc., and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Preparation of 4-(5-(4-(pentyloxy)phenyl)isoxazol-3-yl)benzoic acid-1-benzotriazole ester

[0058]

[0059] Add 4-(5-(4-(pentyloxy)phenyl) isoxazol-3-yl) benzoic acid-1-benzoic acid 0.61kg, DMF5L, THF5L, HOBt0.35kg and EDC.HCl0.61kg, react at room temperature for 3-3.5 hours. After the reaction, 20 L of ethyl acetate and 5 L of purified water were added, filtered and dried to obtain 680 g of the white target product.

Embodiment 2

[0060] Embodiment 2: the preparation of compound II

[0061]

[0062] Add FR1796421.00kg (calculated as anhydrous matter) and DMF10L into a 30L glass reactor, stir and dissolve, and then add DIPEA (N,N-diisopropylethylamine) 0.21kg. Cool the reaction solution to 0-20°C, add the intermediate ① obtained in the previous step, and control the reaction temperature to 0-20°C.

[0063] After the reaction was completed, the reaction solution was poured into 100L of ethyl acetate, and a white solid was precipitated. The white solid was obtained by filtration and dried in vacuo to obtain 1500 g of Compound II.

Embodiment 3

[0064] Embodiment 3: conversion salt purification

[0065]

[0066] Dissolve 500g of compound II in purified water, apply the sample, and elute under the chromatographic conditions in the table below to collect the target components.

[0067]

[0068]

[0069] The prepared solution was collected and concentrated to dryness under reduced pressure to obtain the white product micafungin sodium, which was dried to obtain 235 g.

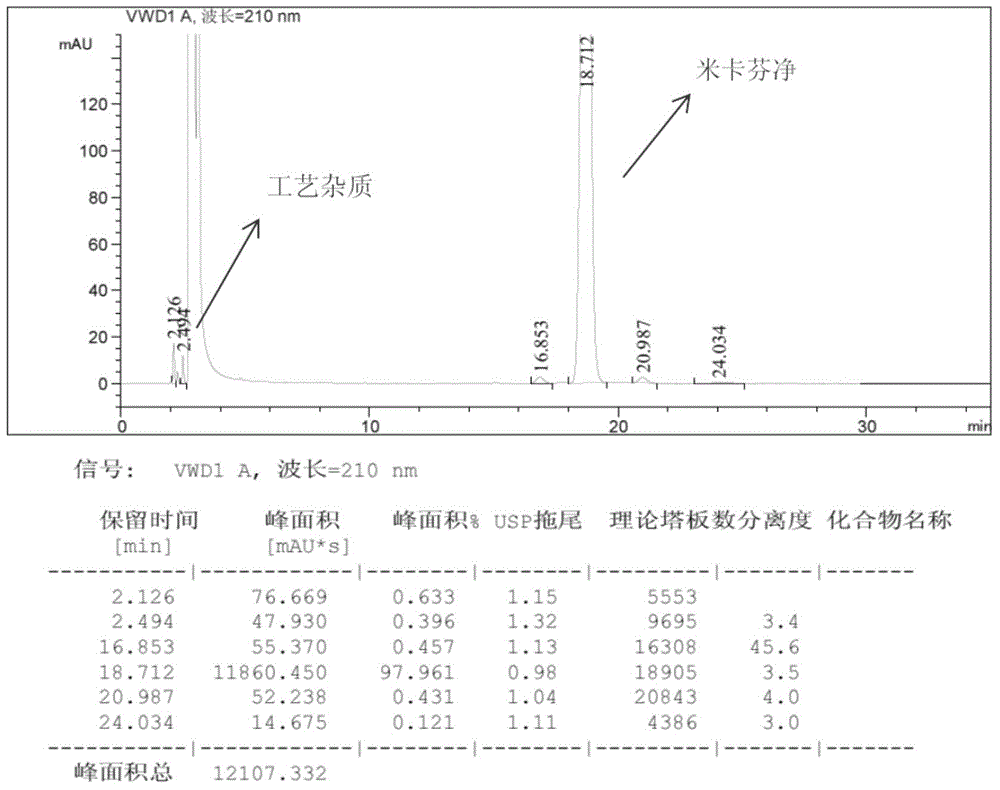

[0070] Gained sample carries out RP-HPLC detection, and purity: 99.1%, and its pattern is as follows image 3 shown.

[0071] Residue on ignition of the sample obtained: 5.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com