A kind of method for preparing high-purity chlorogenic acid from crude extract of Eucommia ulmoides leaves

A technology of crude extract and Eucommia ulmoides leaves, applied in the field of preparing high-purity chlorogenic acid, can solve problems such as no reports, and achieve the effects of promoting rational utilization, expanding raw material sources, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

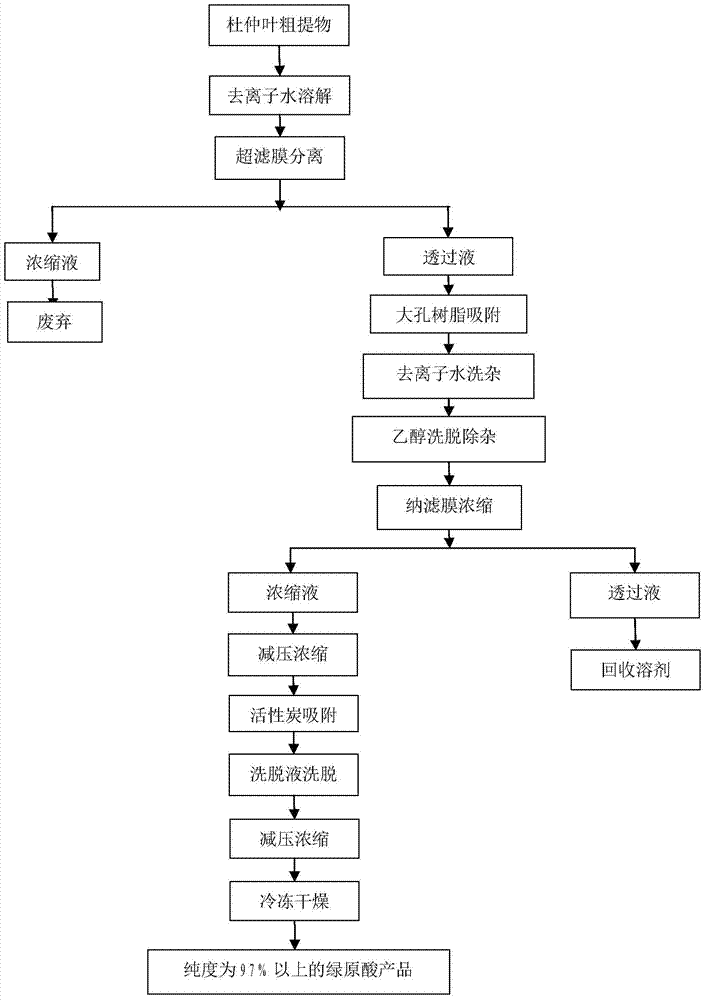

Method used

Image

Examples

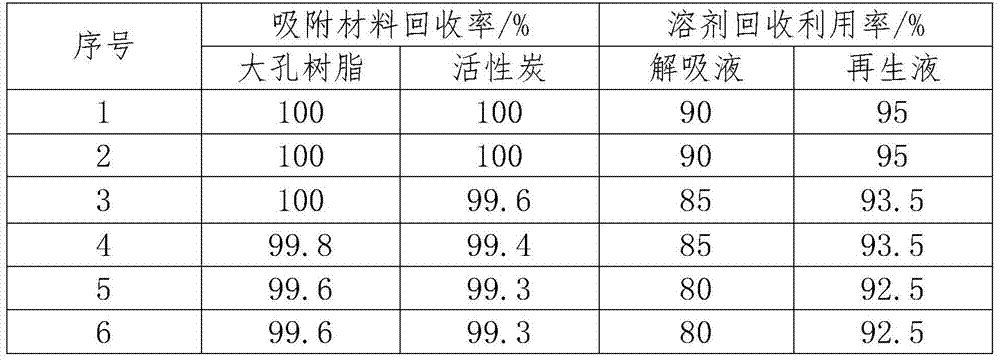

Embodiment 1

[0033] Add 100g Eucommia leaves crude extract, add 500ml water to fully dissolve, stir and prepare the Eucommia leaves crude extract aqueous solution, adjust the pH of the aqueous solution to 4 with a pH meter, first pass the above aqueous solution through an ultrafiltration membrane with a molecular weight cut-off of 1000 for membrane separation, collect Permeate, pass the permeate through NKA-9 macroporous resin at a flow rate of 10BV / h to fully absorb to saturation, and rinse the above macroporous resin column with deionized water at a flow rate of 3BV / h until the effluent is colorless At this time, the NKA-9 type macroporous resin A column and the ADS-8 type macroporous resin B column are connected in series, and then 60% ethanol solution is used to pass through the A column and the B column at a flow rate of 8BV / h for elution and removal. impurity, collect the eluate obtained after impurity removal to high performance liquid chromatography (HPLC) to detect that there is no...

Embodiment 2

[0035]Add 400g of eucommia leaf crude extract, add 4000ml of deionized water to fully dissolve, stir and prepare an aqueous solution of eucommia leaf crude extract, use a pH meter to adjust the pH of the aqueous solution to 4, and pass the above aqueous solution through an ultrafiltration membrane with a molecular weight cut-off of 1000 for membrane separation , collect the permeate, pass the permeate through the ADS-7 macroporous resin at a flow rate of 8BV / h for dynamic adsorption to saturation, and rinse the above macroporous resin column with deionized water at a flow rate of 2BV / h to the effluent Colorless, at this time, connect ADS-7 type macroporous resin column and HPD-300 type macroporous resin column in series first, then use ethanol solution with a volume fraction of 50% to flow through the adsorption column ADS-7 at a flow rate of 7BV / h Type macroporous resin column and impurity removal column HPD-300 type macroporous resin column for elution and impurity removal, c...

Embodiment 3

[0037] 1000g Eucommia leaf crude extract, add 10000ml deionized water to fully dissolve, stir to prepare the Eucommia leaf crude extract aqueous solution, adjust the pH of the aqueous solution to 4 with a pH meter, and pass the above aqueous solution through an ultrafiltration membrane with a molecular weight cut-off of 1000 for membrane separation , collect the permeate, pass the permeate through the ADS-F8 macroporous resin at a flow rate of 5BV / h to absorb to saturation, rinse the above macroporous resin column with deionized water at 6BV / h until the effluent is colorless, At this time, the ADS-F8 type macroporous resin column and the BS-65 type macroporous resin are connected in series, and then the ethanol solution with a volume fraction of 60% is used to pass through the above-mentioned series of columns successively at a flow rate of 8BV / h for elution and removal of impurities. , collect the ethanol eluate and carry out membrane concentration through a nanofiltration mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com