Pure aluminum surface treatment method for aluminum/nickel diffusion bonding

A technology of surface treatment and diffusion connection, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of application limitation, high surface treatment temperature, complex equipment, etc., and achieve improved connection quality, less gaps, and better welding rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

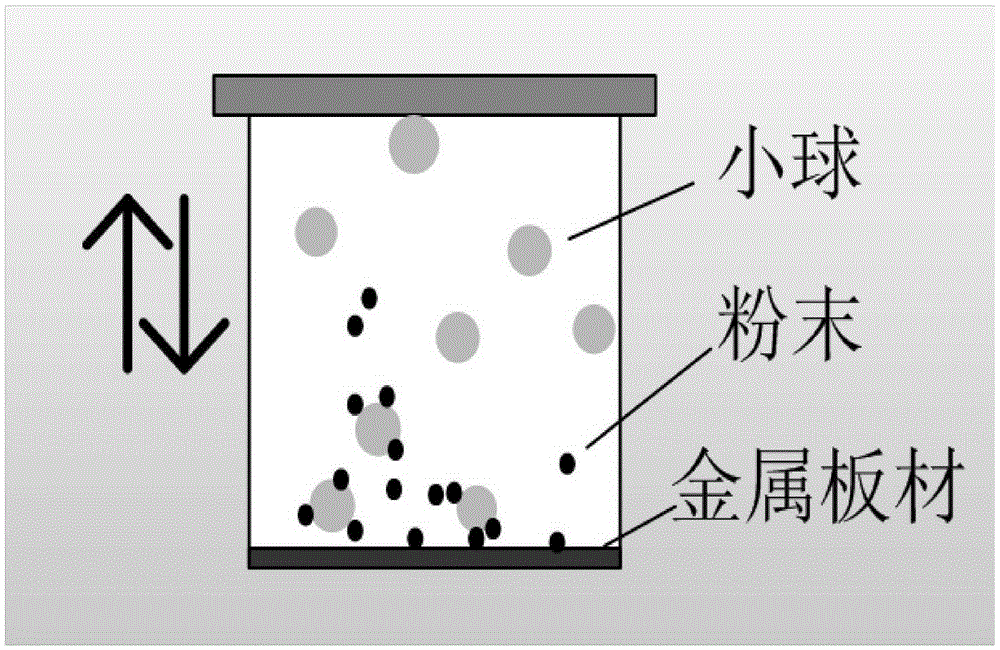

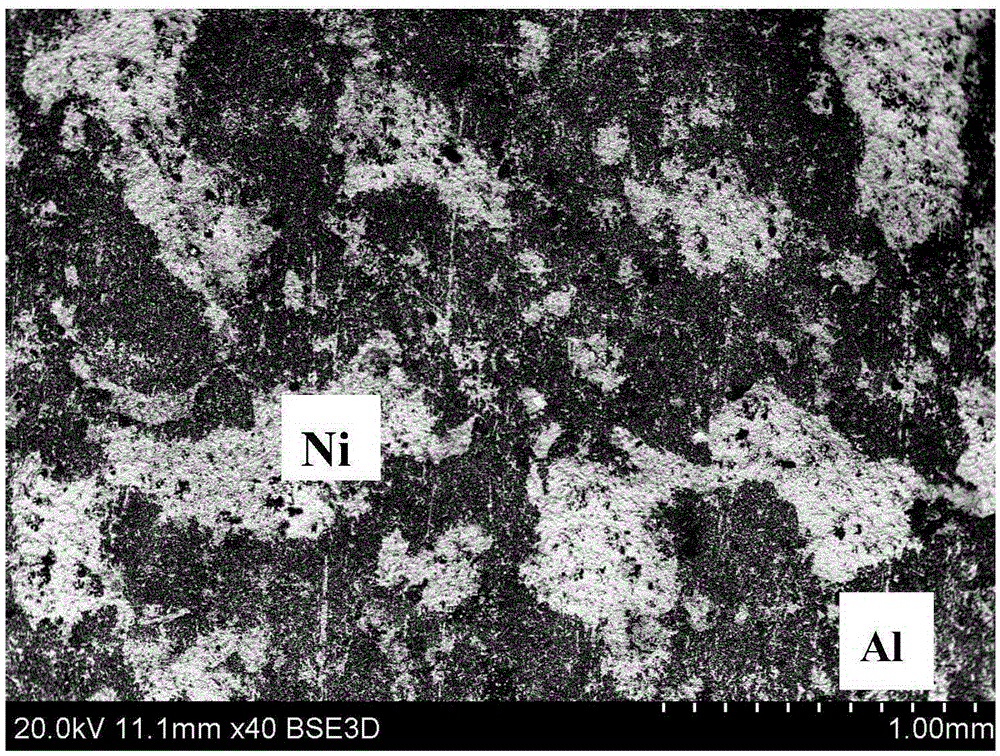

[0020] Specific embodiment one: a kind of pure aluminum surface treatment method that is used for aluminum / nickel diffusion connection of this embodiment, it is to adopt mechanical vibration surface treatment method to process pure aluminum surface; Specific treatment method is as follows:

[0021] After softening and annealing pure aluminum, stick it to the bottom of the stainless steel tank, add nickel powder and stainless steel balls into the tank, rigidly fix the stainless steel tank on a vibrating table that reciprocates up and down, and perform mechanical vibration surface treatment to complete the process. The pure aluminum surface treatment for aluminum / nickel diffusion connection described above; wherein, the mechanical vibration surface treatment conditions are: vibration time 30-60min, vibration amplitude 5mm, vibration frequency 50Hz, ball diameter 2.5-5mm, small The number of balls is 100-200; the amount of nickel powder added is 5-10g.

specific Embodiment approach 2

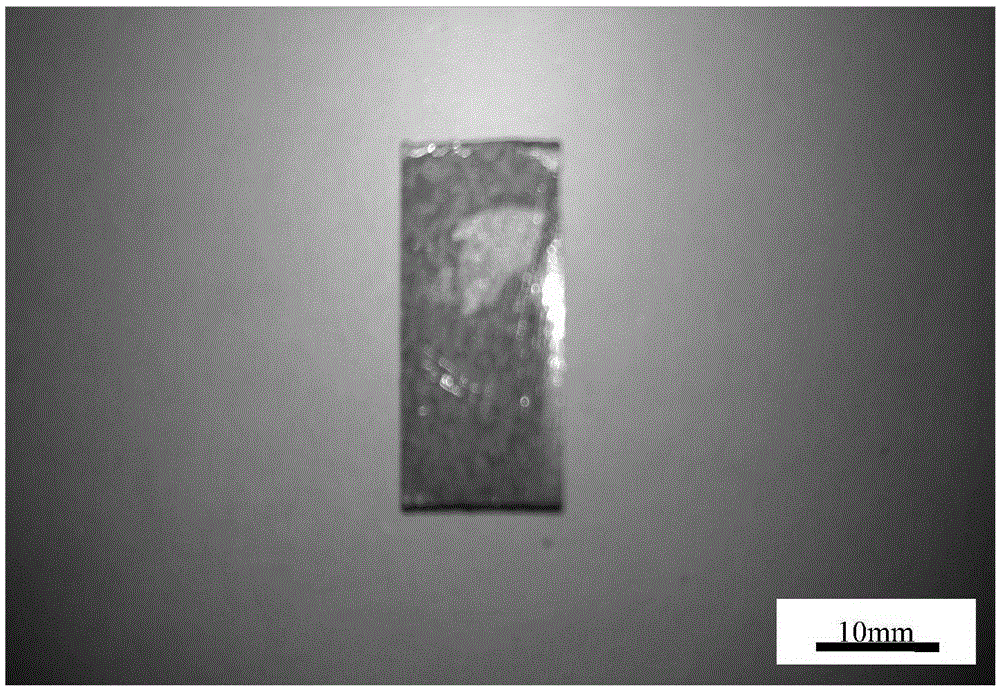

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the pure aluminum is a pure aluminum plate with a thickness of 1.5 mm, a diameter of 6 cm, and a mass purity of 99.9%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 in that the pure aluminum plate is processed into a pure aluminum plate with a thickness of 1.5 mm and a diameter of 6 cm by wire cutting before softening and annealing treatment. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com