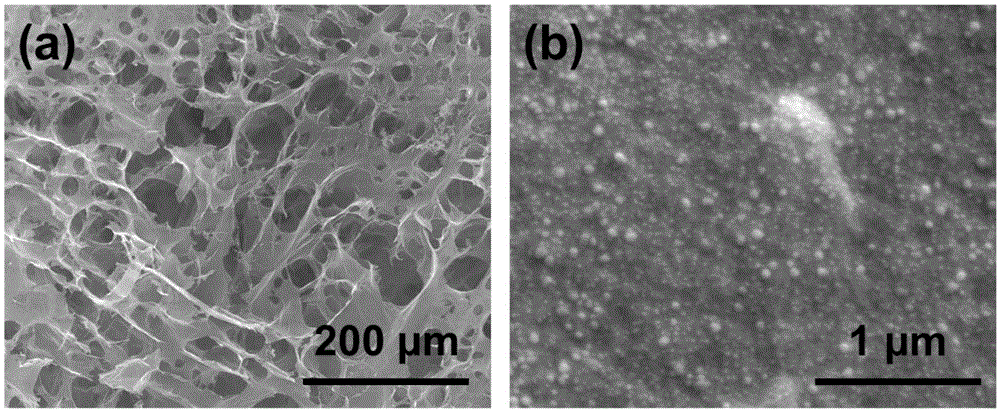

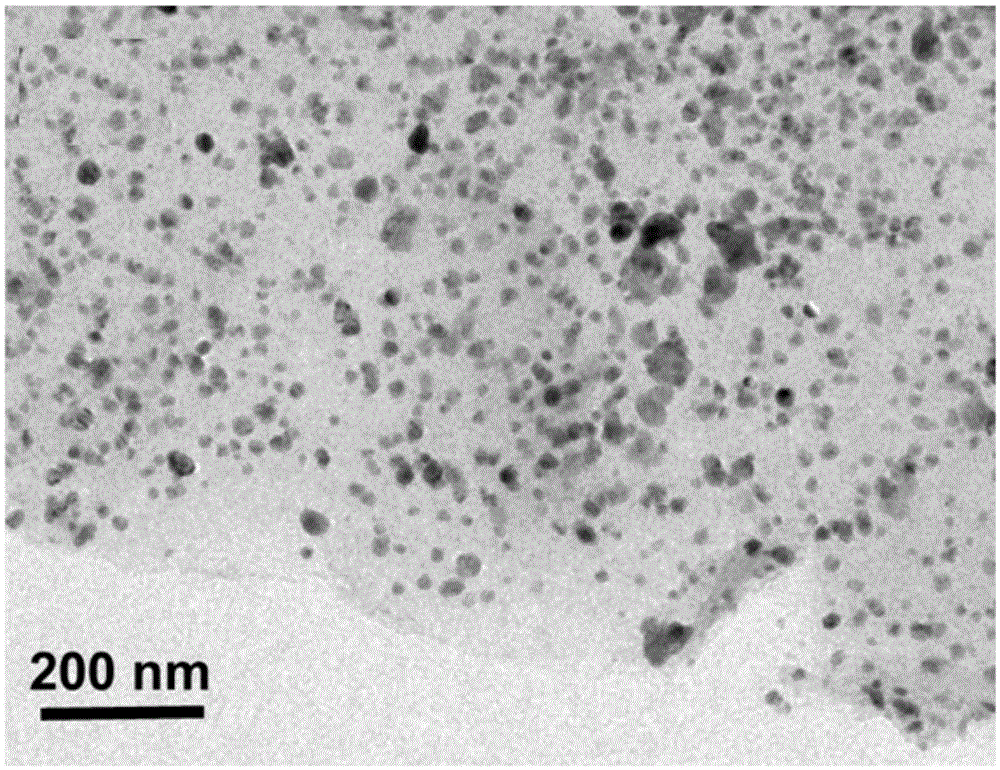

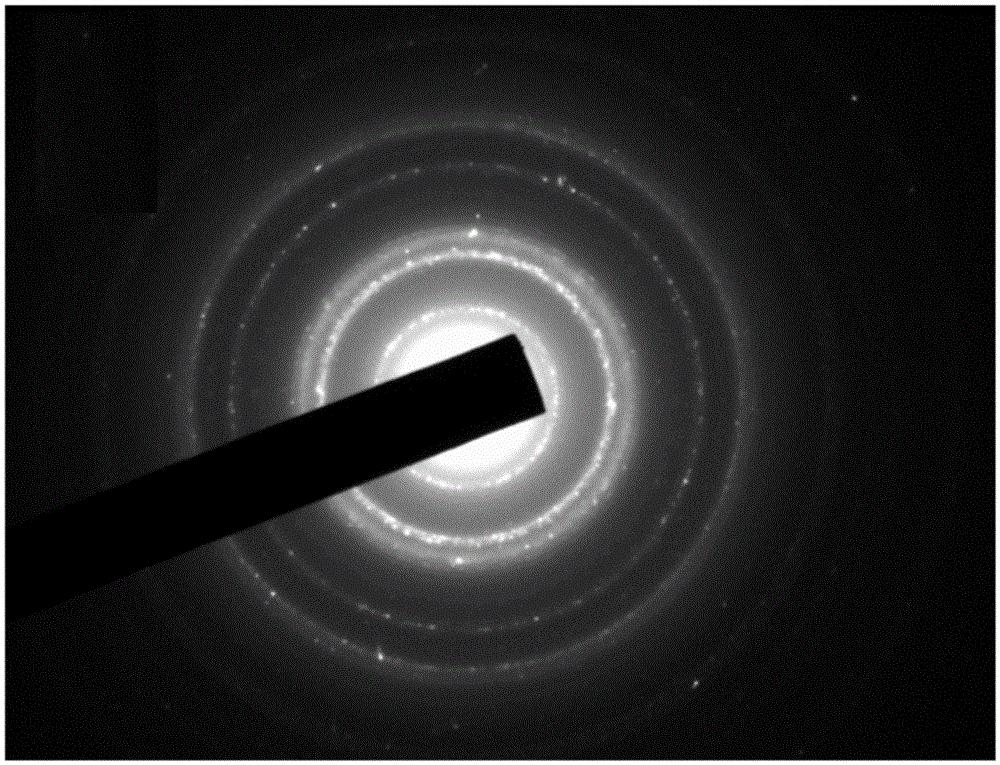

Reduction-oxidation graphene/nanometer metallic silver aerogel with three-dimensional structure and preparation method

A technology of nano-metallic silver and three-dimensional structure, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc. Complicated problems, to achieve good catalytic performance, simple preparation process, and increase the effect of reactive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The first step is to prefabricate graphene oxide. The graphene oxide is prepared in the following way: add 1gNaNO to 40ml of concentrated sulfuric acid solution in a water bath at 10°C 3 and 2g flake graphite; stir at 10°C for 0.5h, and at 15°C for 3.5h; cool to room temperature, dilute with deionized water, separate the supernatant after settling, and dry to obtain graphite after centrifugal filtration; Add 40ml of anhydrous concentrated sulfuric acid and 3g of potassium permanganate to the dried graphite, raise the temperature to 35°C and keep the reaction for 2h; stop heating, add 40ml of deionized water, stir for 1h; add 5ml of 30% hydrogen peroxide solution, and let stand overnight; 5% dilute nitric acid solution was washed several times, and then centrifugally filtered with deionized water several times to obtain the required graphite oxide dispersion.

[0034] In the second step, the above-mentioned graphene oxide solution is diluted to 1 mg / mL graphene oxide aqu...

Embodiment 2

[0039] The first step is to prefabricate graphene oxide. The graphene oxide is prepared in the following way: 1.2g KNO is added to 45ml of concentrated sulfuric acid solution in a water bath at 10°C 3 and 2.4g of graphite flakes; stirred at 11°C for 0.5h, and at 24°C for 3.5h; cooled to room temperature, diluted with deionized water, left to settle, then separated the supernatant, centrifuged and dried to obtain graphite; in a water bath at 15°C, to Add 45ml of anhydrous concentrated sulfuric acid and 4g of potassium permanganate to the above-mentioned dried graphite, heat up to 36°C and keep the reaction for 2h; stop heating, add 44ml of deionized water, stir for 1h; add 7ml of 30% hydrogen peroxide solution, and let stand overnight; Wash with 5% dilute nitric acid solution for several times, and then centrifugally filter with deionized water for several times to obtain the desired graphite oxide dispersion.

[0040] In the second step, the above-mentioned graphene oxide solu...

Embodiment 3

[0045] The first step is to prefabricate graphene oxide, and the graphene oxide is prepared by adding 1.4g KNO to 50ml of concentrated sulfuric acid solution in a water bath at 10°C 3 and 2.8g of graphite flakes; stirred at 12°C for 0.5h, and at 33°C for 3.5h; cooled to room temperature, diluted with deionized water, left to settle, then separated the supernatant, centrifuged and dried to obtain graphite; in a water bath at 15°C, to Add 50ml of anhydrous concentrated sulfuric acid solution and 6g of potassium permanganate to the above-mentioned dried graphite, heat up to 37°C and keep the reaction for 2h; stop heating, add 48ml of deionized water, stir for 1h; add 9ml of 30% hydrogen peroxide solution, and let stand overnight ; wash with 5% dilute nitric acid solution for many times, and then centrifugally filter with deionized water for many times to obtain the required graphite oxide dispersion.

[0046] In the second step, the above-mentioned graphene oxide solution is dilu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com