Graphene-based air filter material and preparation method thereof

A graphene-based, graphene-based technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of inability to filter adsorption materials, three-dimensional graphene has no flexibility, easy to break and deform, etc., and achieve enhanced adsorption effect , good mechanical properties and processing performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The embodiment of the present invention prepares the technological process of three-dimensional graphene, comprises the following steps:

[0031] The first step is to prepare graphene oxide: the average particle size of graphite powder in this example is 5000 mesh. Graphene oxide (GO) was synthesized by the Hummers method. 2g graphite powder, 1gNaNO 3 Mix well with 230ml concentrated sulfuric acid in an ice-water bath, slowly add 6gKMnO 4 . Then the temperature was raised to 35°C, and after stirring for 30 minutes, 92ml of deionized water was added, and the temperature was raised to 98°C for 15 minutes to react. After that, add 280ml of water to it to dilute and wash with 5ml of 30% H 2 o 2 Neutralize excess KMnO 4 . The color of the mixed solution was brownish yellow, filtered while hot, washed repeatedly with deionized water until neutral, and dispersed by ultrasonic to obtain GO.

[0032] The second step is to synthesize three-dimensional graphene: take 200ml...

Embodiment 2

[0037] The embodiment of the present invention prepares the technological process of three-dimensional graphene, comprises the following steps:

[0038] The first step is to prepare graphene oxide: the average particle size of graphite powder in this example is 10000 mesh. The synthesis steps are the same as in Example 1.

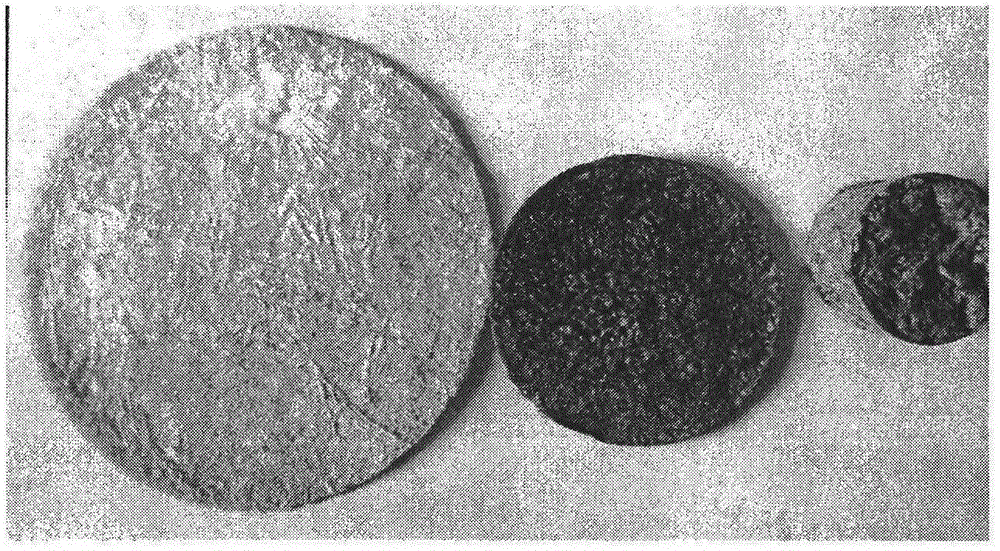

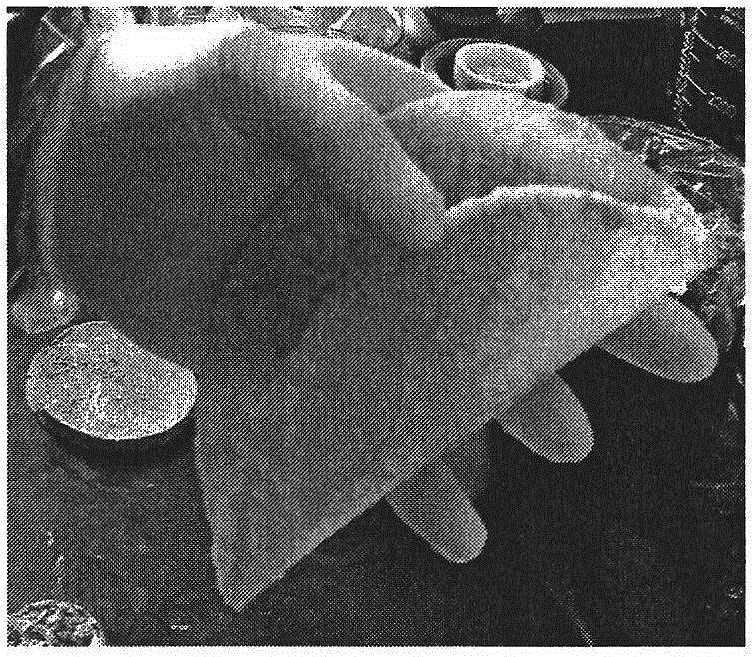

[0039] The second step is to synthesize three-dimensional graphene: take 200ml of graphene oxide solution with a mass fraction of 5mg / ml and pour it into a disc-shaped reaction vessel with a diameter of 25cm and a height of 2cm, add 0.5g of sodium polyacrylate and stir to make it fully mixed, and then Add 100ml of toilet paper pulp. Stir to combine and then freeze into chunks. The graphene sponge was then subjected to vacuum freeze-drying to obtain a flexible three-dimensional graphene structure.

[0040]In summary, the three-dimensional sponge-like graphene structure has a pore size ranging from 100 nm to 1 μm and a specific surface area of about 800 ...

Embodiment 3

[0043] The embodiment of the present invention prepares the technological process of three-dimensional graphene, comprises the following steps:

[0044] The first step is to prepare graphene oxide: the average particle size of graphite powder in this example is 500 mesh. The synthesis steps are the same as in Example 1.

[0045] The second step is to synthesize three-dimensional graphene: take 200ml of graphene oxide solution with a mass fraction of 5mg / ml and pour it into a disc-shaped reaction vessel with a diameter of 25cm and a height of 2cm, add 0.5g of polyethylene glycol and stir to make it fully mixed, Then 100ml of mechanical pulp was added. Stir to combine and then freeze into chunks. The graphene sponge was then subjected to vacuum freeze-drying to obtain a flexible three-dimensional graphene structure.

[0046] In summary, the three-dimensional sponge-like graphene structure has a pore size ranging from 100 nm to 1 μm and a specific surface area of about 200 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com