Broad bean protein meat and preparation method thereof

A protein meat and broad bean technology, which is applied in the field of broad bean protein meat and its preparation, can solve the problems of not being able to satisfy consumers and the protein content of protein meat is not rich enough, and achieve the effects of enriching product types, wide application groups, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

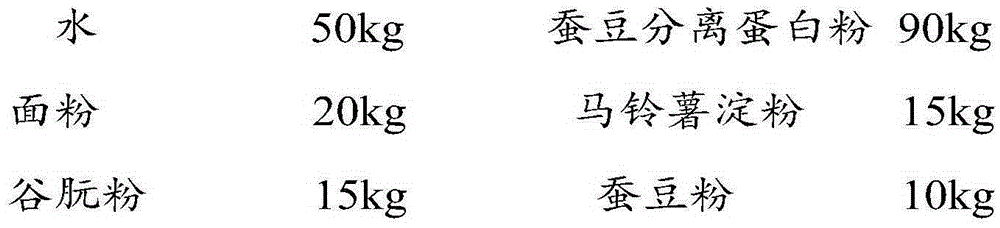

[0033] The raw material composition of broad bean protein meat is:

[0034]

[0035] The specific preparation method of broad bean protein meat is as follows:

[0036] 1) Buy fresh and high-quality broad bean protein isolate powder, flour, potato starch, gluten powder, broad bean powder and other raw materials from the market, weigh the raw and auxiliary materials according to the above ratio and mix them evenly;

[0037] 2) Use 1mol / L sodium hydroxide to adjust the pH value of the distilled water to 11, add an alkaline aqueous solution and adjust the pH value of the raw and auxiliary materials to be between 7-9, the water content to 50 wt%, and fully stir to form a ball;

[0038] 3) The raw and auxiliary materials with adjusted moisture are extruded with high moisture content through a twin-screw extruder. The barrel temperature of the extruder is between 60°C and 150°C, the screw speed is 500rad / min, and the feeding speed is 500rad / min;

[0039] 4) Press the textured pro...

Embodiment 2

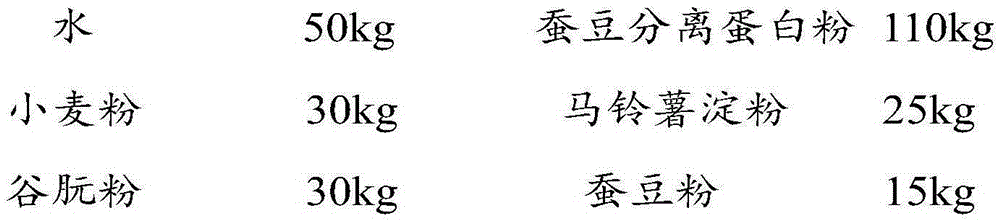

[0041] The raw material composition of broad bean protein meat is:

[0042]

[0043] The specific preparation method of broad bean protein meat is as follows:

[0044] 1) Buy fresh and high-quality broad bean protein isolate powder, flour, potato starch, gluten powder, broad bean powder and other raw materials from the market, weigh the raw and auxiliary materials according to the above ratio and mix them evenly;

[0045] 2) Use 2mol / L sodium hydroxide to adjust the pH value of the distilled water to 11, add an alkaline aqueous solution and adjust the pH value of the raw and auxiliary materials to be between 7-9, the water content to 60wt%, and fully stir to form a ball;

[0046] 3) The raw and auxiliary materials with adjusted moisture are extruded with high moisture content through a twin-screw extruder. The barrel temperature of the extruder is divided into three temperature ranges. The temperature in the first zone is 50°C, and the temperature in the second zone is 155°...

Embodiment 3

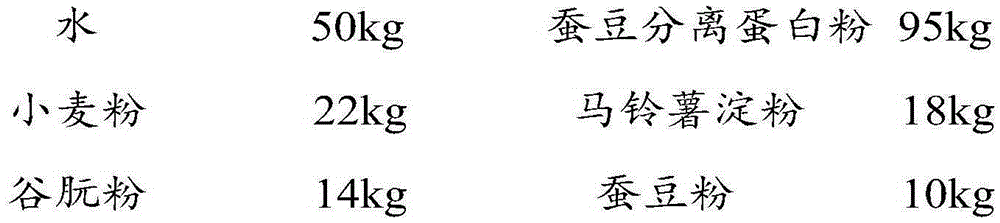

[0049] The raw material composition of broad bean protein meat is:

[0050]

[0051] The specific preparation method of broad bean protein meat is as follows:

[0052] 1) Buy fresh and high-quality broad bean protein isolate powder, flour, potato starch, gluten powder, broad bean powder and other raw materials from the market, weigh the raw and auxiliary materials according to the above ratio and mix them evenly;

[0053] 2) Use 1.5 mol / L sodium hydroxide to adjust the pH value of distilled water to 11, add alkaline aqueous solution and adjust the pH value of the raw and auxiliary materials to be between 7-9, the water content to 55 wt%, and fully stir to form a ball;

[0054] 3) The raw and auxiliary materials with adjusted moisture are extruded with high moisture content through a twin-screw extruder. The barrel temperature of the extruder is divided into three temperature ranges. The temperature in the first zone is 55°C, and the temperature in the second zone is 159°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com