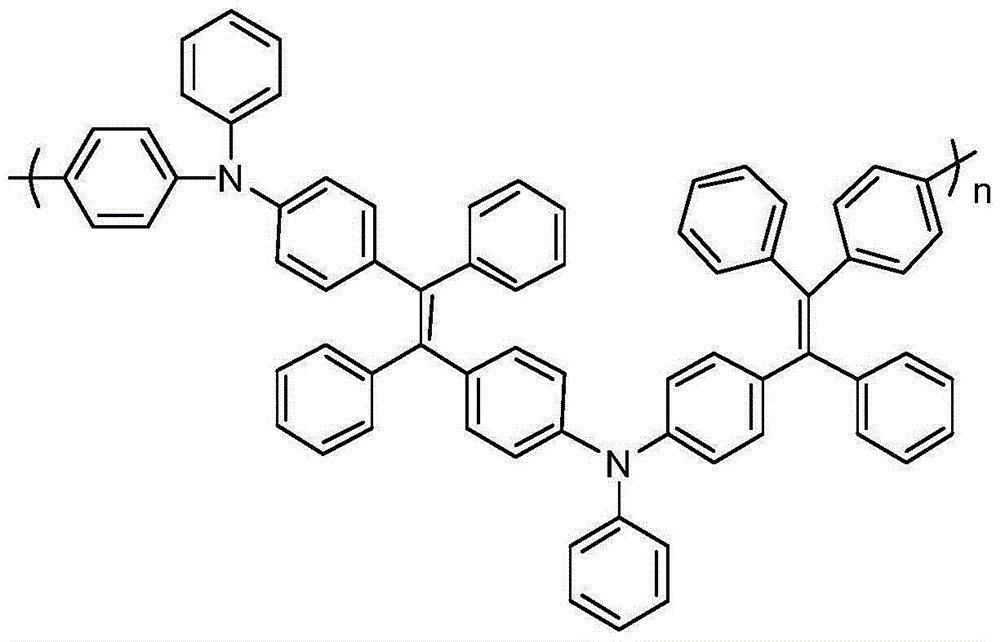

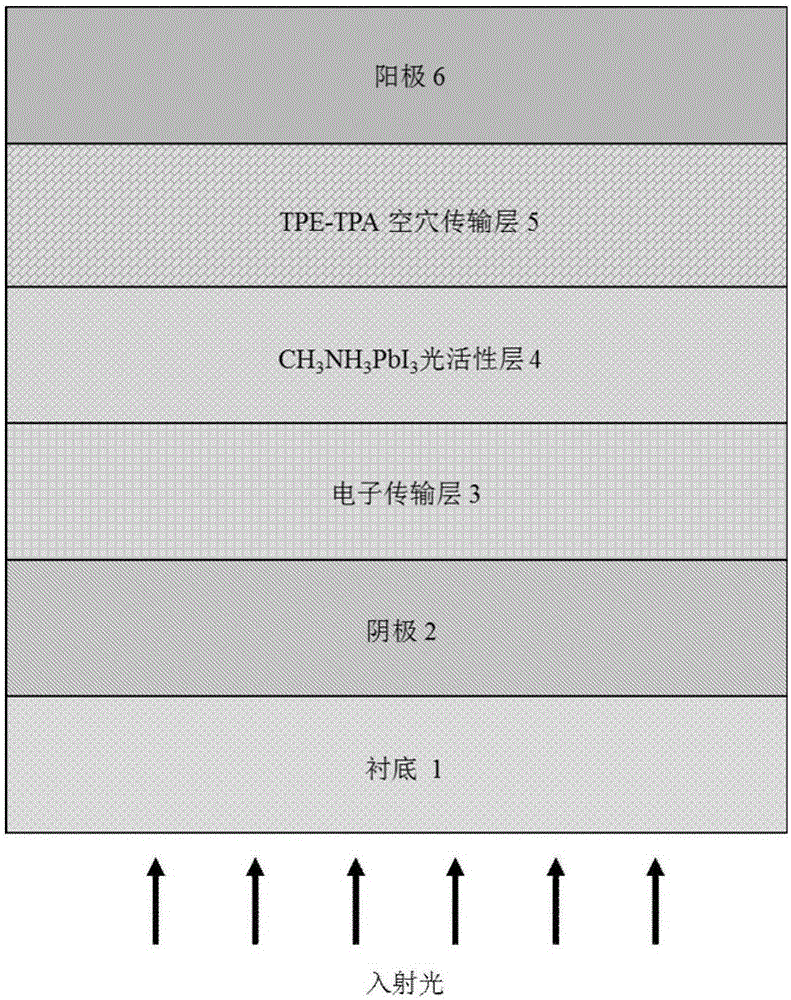

Tetraphenyl ethylene polymer hole transport layer-based perovskite solar cell

A technology of hole transport layer and solar cell, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems that restrict the commercial production of perovskite solar cell efficiency, low carrier mobility, and unstable properties. Achieve high yield, simple synthesis steps and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

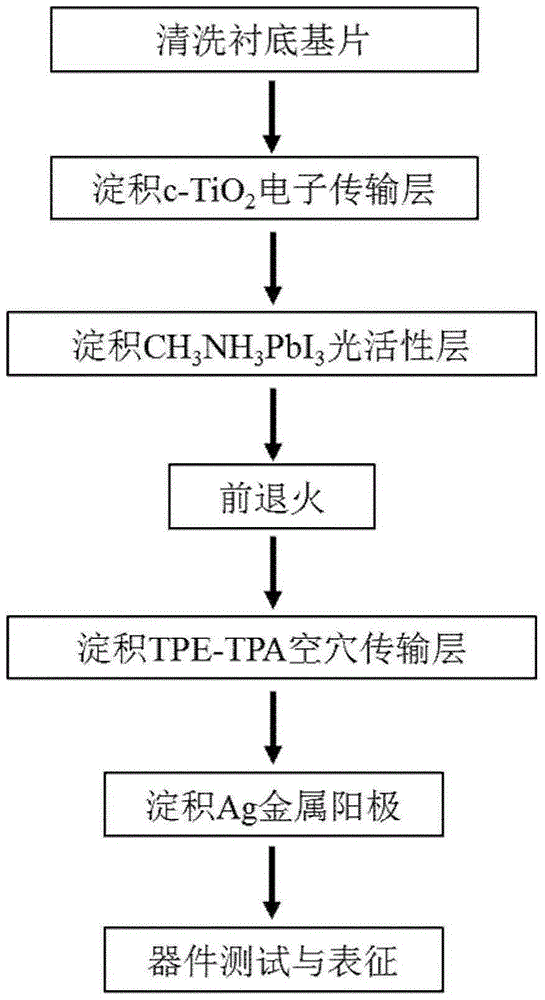

[0055] Example 1, making a solar cell with a TPE-TPA hole transport layer thickness of 80 nm.

[0056] Step 1, cleaning the substrate substrate.

[0057] The 1.9mm glass substrate with fluorine-doped tin oxide FTO was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 15 minutes, and dried with a nitrogen gun after cleaning.

[0058] Step 2, depositing c-TiO on the cleaned substrate 2 electron transport layer.

[0059] 2a) Preparation of precursor solution:

[0060] Take 1.464mL of 75% mass fraction of diisopropyl diacetylacetonate titanate TiAc solution, add 18.536mL of 1-butanol to the solution for dilution, and ultrasonicate the diluted solution for 15min to obtain 0.15M / L c-TiO 2 Precursor solution;

[0061] 2b) Spin coating c-TiO 2 Precursor solution:

[0062] Spin-coat c-TiO on the cleaned substrate 2 Precursor solution, spin-coating speed is 5000r / min, spin-coating time is 50s, and annealed on a hot stage at a temperatur...

Embodiment 2

[0080] Example 2, making a solar cell with a TPE-TPA hole transport layer thickness of 100 nm.

[0081] Step 1: Place the 1.9 mm quartz substrate containing fluorine-doped tin oxide FTO in deionized water, acetone, absolute ethanol and deionized water for 15 minutes for ultrasonic cleaning, and dry it with a nitrogen gun after cleaning.

[0082] Step 2, depositing c-TiO on the cleaned substrate 2 electron transport layer.

[0083] 2.1) Preparation of precursor solution:

[0084] The concrete realization of this step is identical with step 2a) of embodiment 1;

[0085] 2.2) Spin coating c-TiO 2 Precursor solution:

[0086] Spin-coat c-TiO on the cleaned substrate 2 The precursor solution was spin-coated at a speed of 4000r / min for 50s, and annealed on a hot stage at a temperature of 500°C for 15min to obtain c-TiO with a thickness of 90nm 2 electron transport layer.

[0087] Step 3, on c-TiO 2 CH deposition on the electron transport layer 3 NH 3 PB 3Photoactive layer...

Embodiment 3

[0101] Example 3, making a solar cell with a TPE-TPA hole transport layer thickness of 200 nm.

[0102] Step A, cleaning the substrate substrate.

[0103] The 1.9 mm glass substrate containing fluorine-doped tin oxide FTO was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 15 minutes, and dried with a nitrogen gun after cleaning.

[0104] Step B, depositing c-TiO on the cleaned substrate 2 electron transport layer.

[0105] B1) Preparation of precursor solution:

[0106] The concrete realization of this step is identical with step 2a) of embodiment 1;

[0107] B2) Spin-coating c-TiO 2 Precursor solution:

[0108] Spin-coat c-TiO on the cleaned substrate 2 solution, spin-coated at a speed of 3000r / min for 50s, and annealed on a hot stage at a temperature of 500°C for 15min to obtain c-TiO with a thickness of 100nm 2 electron transport layer.

[0109] Step C, on c-TiO 2 CH deposition on the electron transport layer 3 NH 3 P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com