Mask-assisted method for preparing porous GaN layer

A mask and mask pattern technology, which is applied in the field of mask-assisted preparation of porous GaN layers, can solve the problems of rough peeling interface and unguaranteed integrity, and achieve the effects of uniform porous GaN layer and simple production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

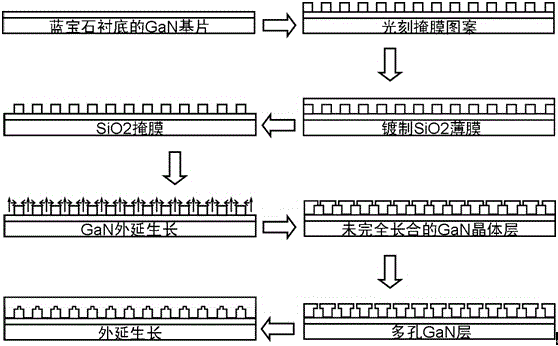

[0016] A method for mask-assisted preparation of a porous GaN layer, the process steps are:

[0017] (1) Preparation of SiO2 stripe mask on GaN substrate

[0018] a) Using HVPE equipment, grow a layer of GaN film with a thickness of about 5 μm on the 2inchc surface sapphire as the substrate,

[0019] b) Photolithographic strip mask, uniformly coat a layer of photoresist on the GaN substrate with a coating machine, then bake the glue on a heating platform at about 70°C for 10 minutes, and then use a strip mask plate on the photolithography machine Exposure, the exposure time is 25s. After the exposure is over, use KOH aqueous solution or other developer with a ratio of 1:50 to develop. The development time is controlled at about 1min. Finally, dry the glue at 70°C to obtain strip light engraved mask,

[0020] c) open the magnetron sputtering apparatus, on the GaN substrate with mask pattern by adjusting the sputtering power and sputtering time to plate a SiO2 film with a thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com