Multi-longitudinal-vortex sine/cosine-line enhanced heat transferring tube

A longitudinal vortex, heat transfer tube technology, applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low comprehensive heat transfer performance, small application range, uncontrollable eddy current, etc., to improve the flow field and The degree of synergy of the temperature field, the effect of flexible use, and high-intensity fluid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

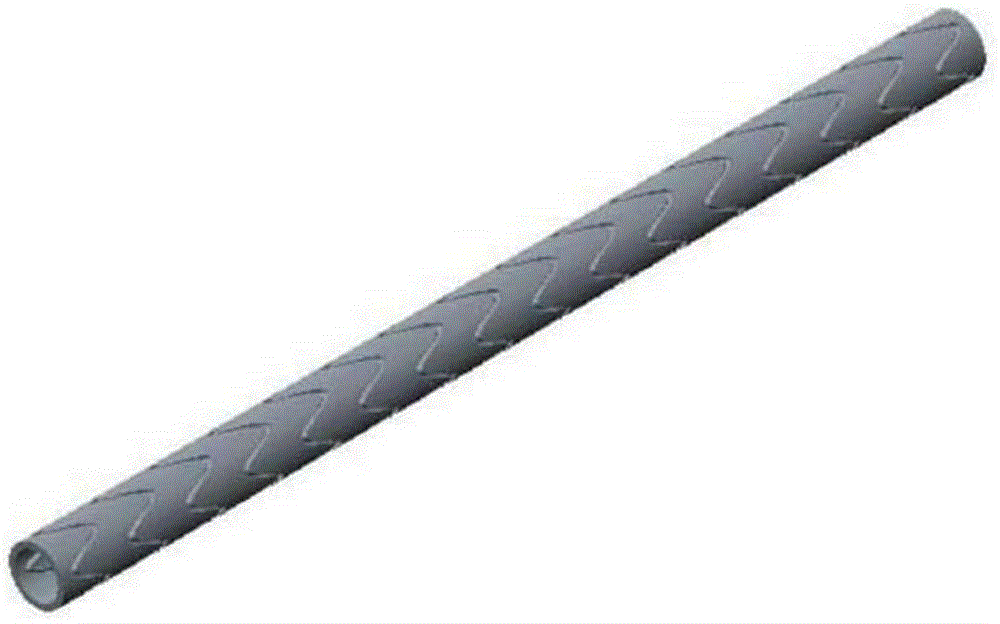

Embodiment 1

[0040] as attached Figure 3~5 As shown, the body rib pitch of the sine (co)sine pattern enhanced heat transfer tube with multiple longitudinal vortices L =20mm, rib amplitude A =12mm, the number of ribs in the circumferential direction n =2, outer diameter d =19mm, wall thickness t =2mm, rib height e =0.8mm, when applied, leave a certain distance between the two ends of the enhanced heat transfer tube, and then insert it into the tube sheet of the shell-and-tube heat exchanger, and use the method of expansion joint or welding or expansion welding to enhance heat transfer Tube fixation. In use, the fluid enters from one end of the tube, and under the induction of positive (cosine) strings, multiple longitudinal vortices along the flow direction are generated, forming radial fluid flow impacting the tube wall and radial fluid flow leaving the tube wall, reducing The angle between the velocity vector and the temperature gradient vector in the tube is reduced, which is lowe...

Embodiment 2

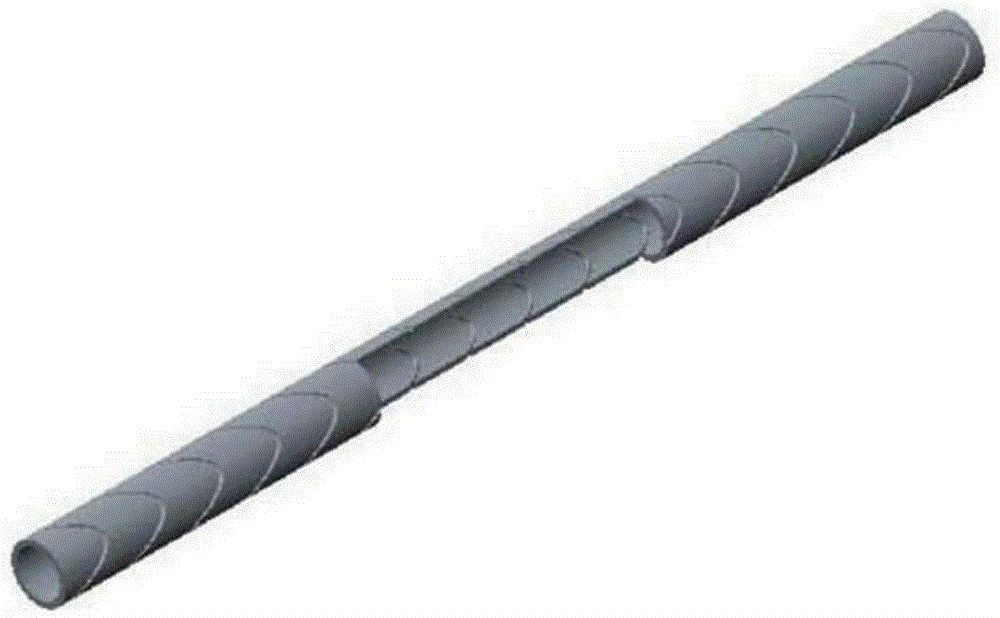

[0042] as attached Figure 6~8 As shown, the body rib pitch of the sine (co)sine pattern enhanced heat transfer tube with multiple longitudinal vortices L =30mm, rib amplitude A =16mm, the number of circumferential ribs n =4, outer diameter d =32mm, wall thickness t =3mm, rib height e =0.8mm, under common working conditions, the heat transfer rate is more than 50% higher than that of smooth tubes. Under the same power consumption, compared with smooth tubes, the maximum comprehensive heat transfer performance exceeds 1.2. Application method is the same as embodiment 1.

Embodiment 3

[0044] as attached Figure 9~11 As shown, the body rib pitch of the sine (co)sine pattern enhanced heat transfer tube with multiple longitudinal vortices L =25mm, rib amplitude A =12mm, the number of circumferential ribs n =6, outer diameter d =57mm, wall thickness t =3.5mm, rib height e =1.5mm, under common working conditions, the heat transfer rate is at most 1.3 times higher than that of smooth tubes, and under the same power consumption, compared with smooth tubes, the overall heat transfer performance is at most more than 1.4. Application method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com