Servo pump control hydraulic system

A hydraulic system and servo pump technology, applied in servo motors, servo motor components, fluid pressure actuating devices, etc., can solve the problems of low efficiency of hydraulic systems, large throttling losses, and difficulty in further improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

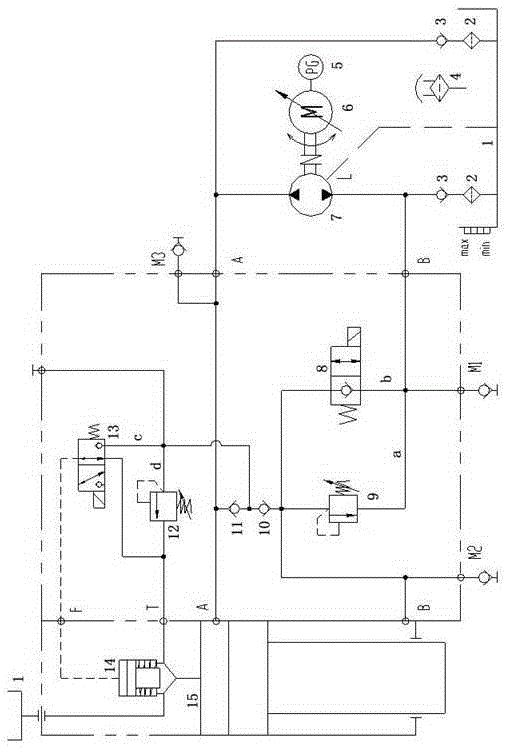

[0017] In order to clearly illustrate the technical features of the present solution, the present solution will be described below through specific embodiments and in conjunction with the accompanying drawings.

[0018] A servo pump-controlled hydraulic system includes an oil cylinder 15 and a bidirectional hydraulic pump 7 driven by a servo motor 6. The output shaft of the servo motor 6 is connected with the drive shaft of the hydraulic pump 7, and the servo motor 6 drives the hydraulic pump 7 clockwise or counterclockwise. Clock operation and stop of hydraulic pump 7 . The servo motor 6 has a built-in encoder 5, which is used to measure the angular displacement and rotational speed of the servo motor 6, and feed back the corresponding signal to the servo motor driver to form a closed-loop control loop, which improves the efficiency of the servo motor 6 to drive the hydraulic pump 7. control precision. Relying on the displacement sensor measuring the position of the piston r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com