Movable cantilever frame device for civil engineering construction

A kind of industrial and civil engineering, mobile technology, applied in the direction of construction, building structure, scaffolding accessories, etc., can solve the problems of poor overall use effect, automatic downward movement of the bearing plate, broken and slipped bolts, etc., to achieve convenient stability and safety. Use, prevent self-dropping, and balance the effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

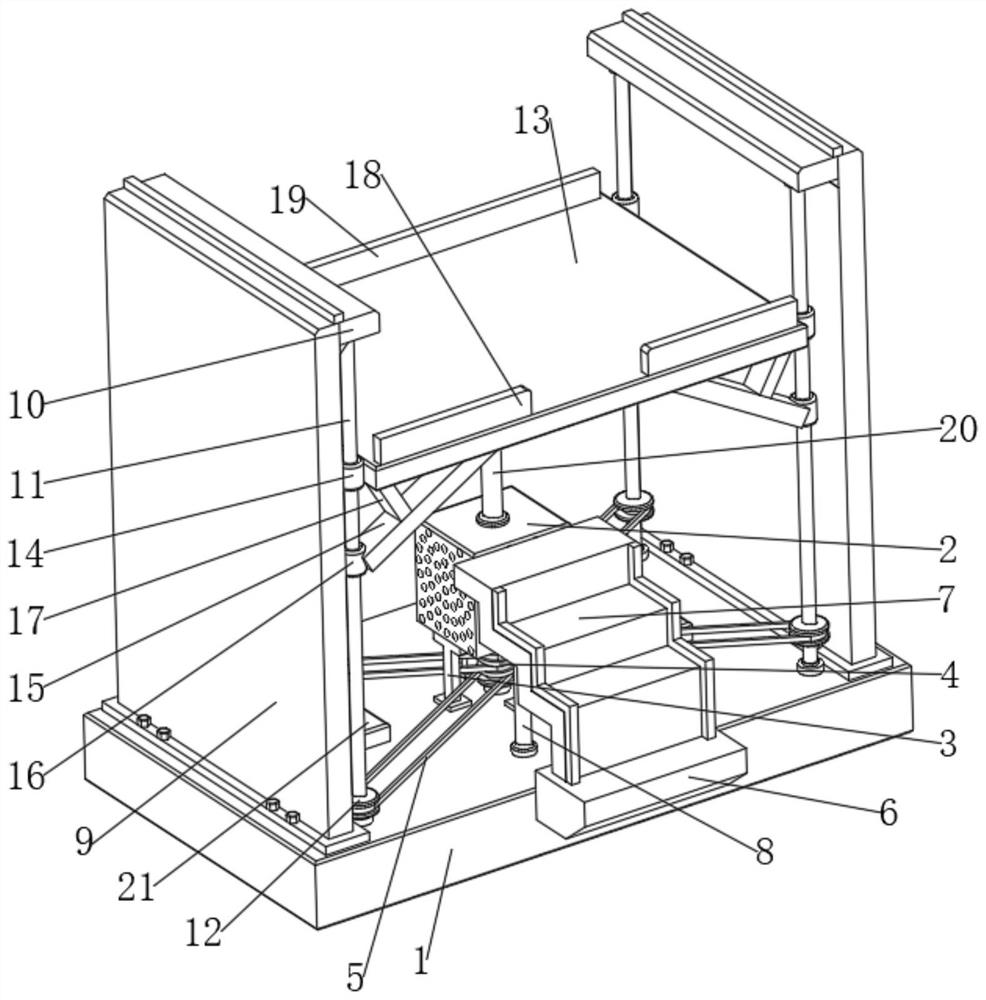

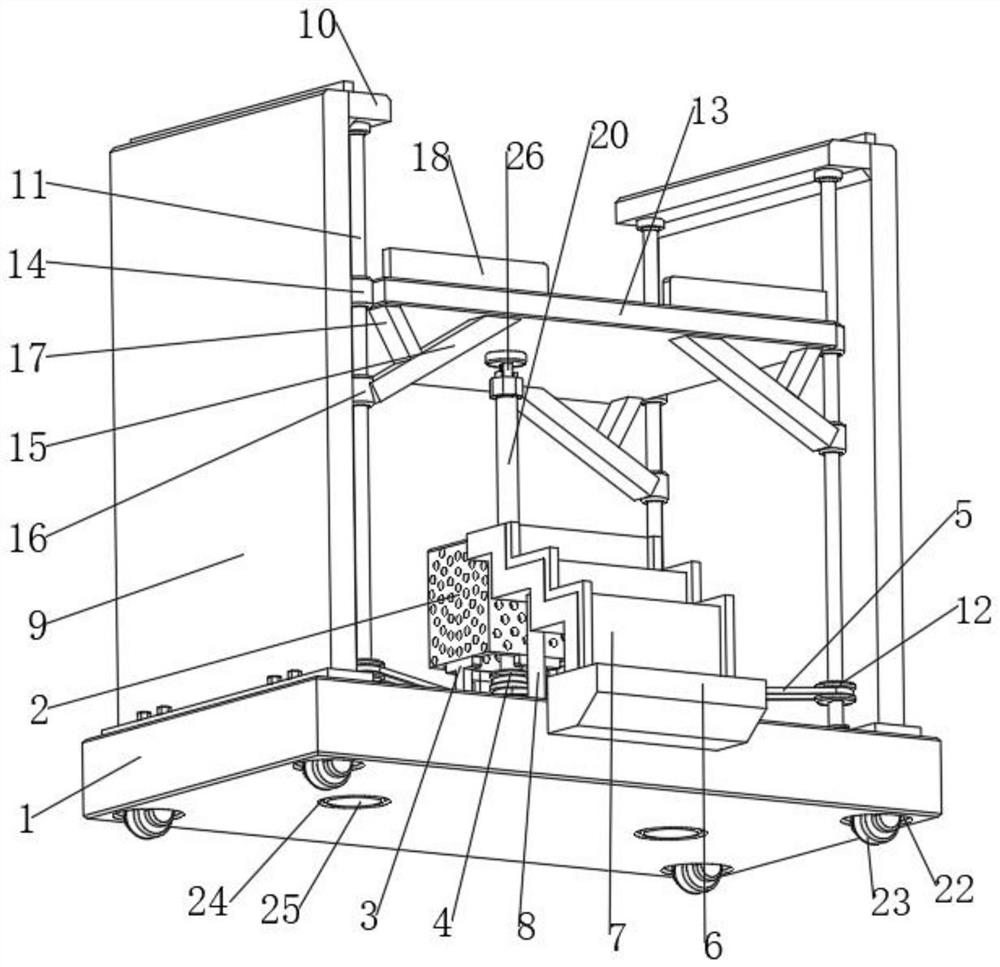

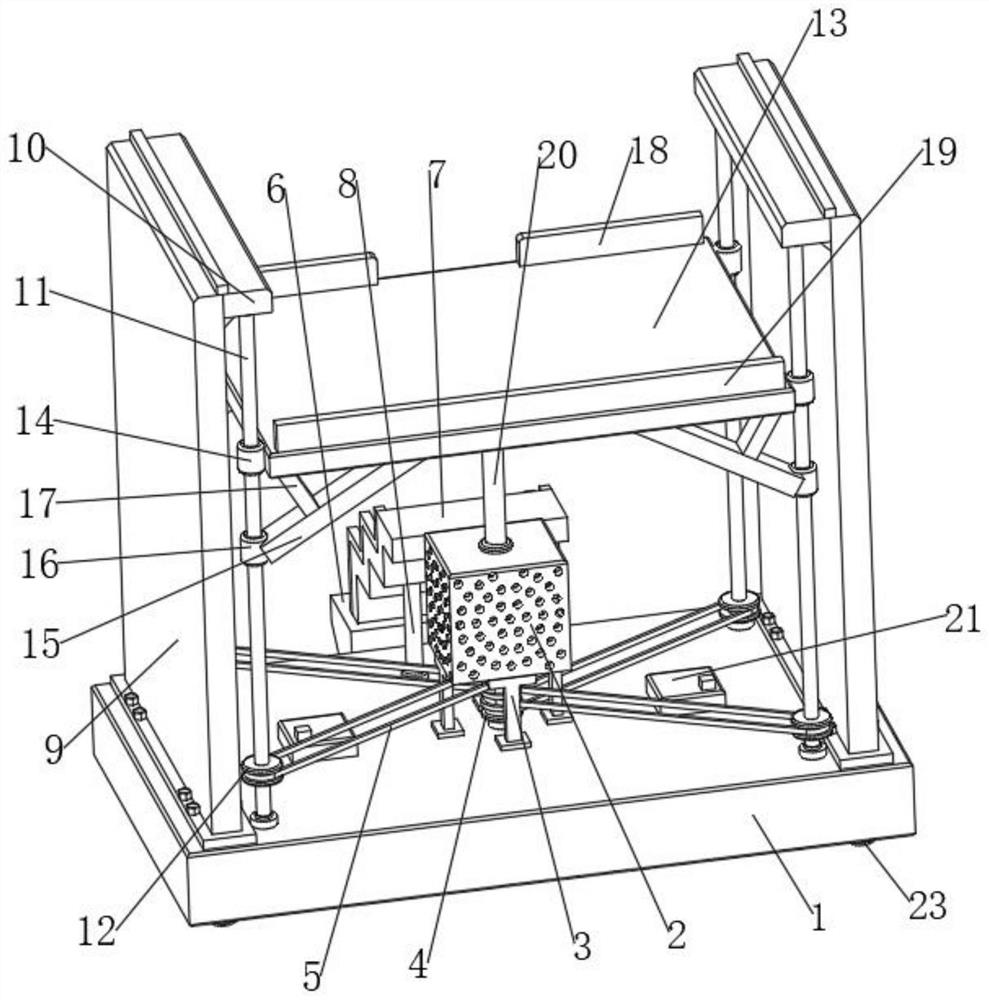

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6, the present invention provides the following technical solutions: a movable pick-up device for industrial and civil construction projects, comprising a base plate 1, a chassis 2 is arranged in the middle position of the upper end of the base plate 1, and a number of support rods are arranged around the bottom of the chassis 2. 3. The upper and lower ends of the support rod 1 3 are respectively fixedly connected with the bottom end of the chassis 2 and the upper end of the bottom plate 1, and the support rod 1 3 is a "T"-shaped structure. The inner upper end of the chassis 2 is fixed with a positive and negative motor 27, the output end of the positive and negative motor 27 is provided with a transmission shaft, and the bottom end of the transmission shaft is fixed with a main pulley 4, and the bottom end of the main pulley 4 and the upper end of the bottom plate 1 pass through The rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com