Pre-former for steel cord or steel wire rope

A pre-deformer and steel wire rope technology, applied in the field of steel cord or steel wire rope manufacturing, can solve the problems of limited residual torsional adjustment effect of steel wire, poor glue penetration, fixed deformation, etc., to reduce strength and coating loss, and reduce friction coefficient. , the effect of improving damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

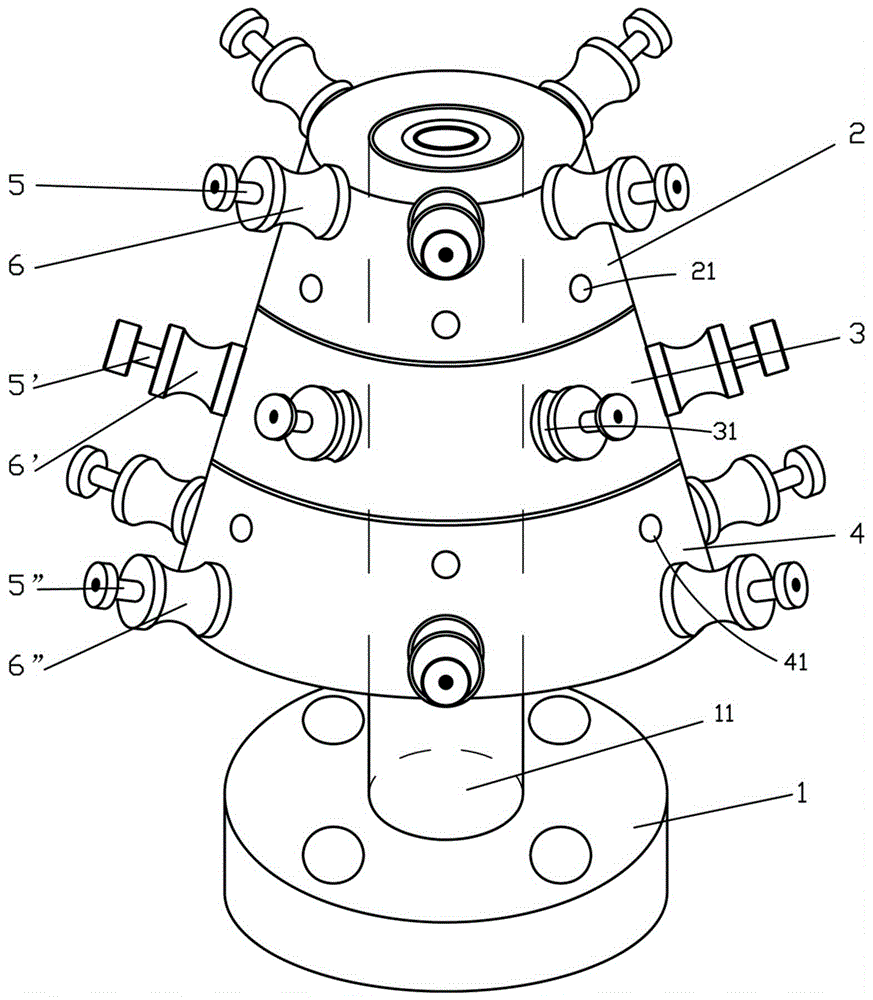

[0023] See figure 1 , A pre-deformer for steel cords or steel ropes of the present invention includes a base 1 with a through hole in the center and a hollow shaft 11 in the through hole; upper, middle, and lower adjustment discs 2, 3 , 4, respectively are round table bodies with a central hole, the outer surfaces of the three adjustment discs are in a straight line, forming a round table body structure with upper, middle and lower adjustment discs 2, 3 and 4 On the hollow shaft 11 of the base 1, the upper and lower adjustment discs 2 and 4 are fixedly connected to the hollow shaft 11, the middle adjustment disc 3 is a rotatable structure; the outer surfaces of the upper and lower adjustment discs 2, 4 are evenly provided with two rows of screw holes in the circumferential direction 21, 41, the screw holes 21, 41 on the upper and lower adjusting discs 2, 4 are arranged correspondingly, that is, on the same straight line, a row of screw holes 31 are evenly arranged on the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com