Thermal spraying coating layer antireflection layer suitable for solar selective absorption and preparation method thereof

A technology of thermal spraying and anti-reflection layer, applied in the direction of coating, metal material coating process, liquid chemical plating, etc., can solve the problem of reducing the service life and optical performance of the coating, increasing the infrared emissivity, and increasing the surface stress and other problems, to achieve excellent optical selectivity, improve the absorption-emission ratio, and relieve the effect of stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

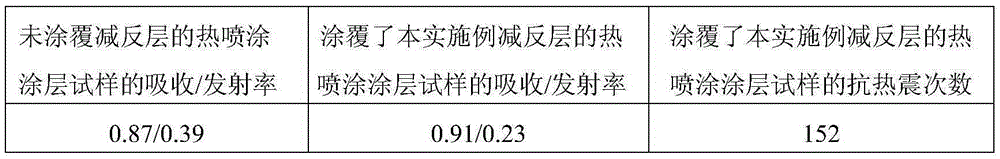

Embodiment 1

[0030] A thermal spray coating anti-reflection layer suitable for selective absorption of solar energy is prepared by the following method:

[0031] (1)CuMnO x Preparation of composite sol:

[0032] a. Preparation of CuMnO by sol-gel method x Sol: Weigh 5.1144g CuCl respectively 2 , 7.3527gMn(CH 3 COO) 2 and 12.6084g citric acid, measure 100ml ethanol, the CuCl 2 and Mn(CH 3 COO) 2 Add it into ethanol, magnetically stir until completely dissolved, and prepare a mixed solution A of 0.3mol / L; measure 100ml of ethanol, add the weighed citric acid into ethanol, magnetically stir until completely dissolved, and prepare solution B; Slowly add solution B to mixed solution A to obtain solution C, adjust the temperature of the water bath to 60°C, stir at constant temperature for 2 hours, add ammonia water with a concentration of 0.5mol / L dropwise during the stirring process, adjust the pH value of the solution to 6.5, and continue stirring until Stop when the solution volume is...

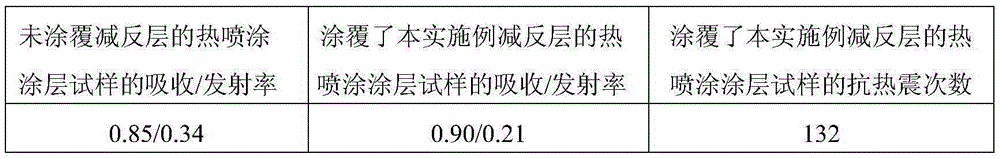

Embodiment 2

[0039] A thermal spray coating anti-reflection layer suitable for selective absorption of solar energy is prepared by the following method:

[0040] (1)CuMnO x Preparation of composite sol:

[0041] a. Preparation of CuMnO by sol-gel method x Sol: Weigh 6.8192g CuCl respectively 2 , 9.8036gMn(CH 3 COO) 2 and 16.8112g citric acid, measure 100ml ethanol, the CuCl 2 and Mn(CH 3 COO) 2 Add it into ethanol, magnetically stir until completely dissolved, and prepare a mixed solution A of 0.4mol / L; measure 100ml of ethanol, add the weighed citric acid into ethanol, magnetically stir until completely dissolved, and prepare solution B; Slowly add solution B to mixed solution A to obtain solution C, adjust the temperature of the water bath to 60°C, stir at constant temperature for 2 hours, add ammonia water with a concentration of 0.5mol / L dropwise during the stirring process, adjust the pH value of the solution to 6.5, and continue stirring until Stop when the solution volume is...

Embodiment 3

[0049] A thermal spray coating anti-reflection layer suitable for selective absorption of solar energy is prepared by the following method:

[0050] (1)CuMnO x Preparation of composite sol:

[0051] a. Weigh 5.6268g Cu (NO 3 ) 2 , 7.3527gMn(CH 3 COO) 2 and 12.6084g citric acid, measure 100ml ethanol, the Cu(NO 3 ) 2 and Mn(CH 3 COO) 2 Add it into ethanol, magnetically stir until completely dissolved, and prepare a mixed solution A of 0.3mol / L; measure 100ml of ethanol, add the weighed citric acid into ethanol, magnetically stir until completely dissolved, and prepare solution B; Slowly add solution B to mixed solution A to obtain mixed solution C. Adjust the temperature of the water bath to 60°C and stir at a constant temperature for 2 hours. During the stirring process, add ammonia water with a concentration of 0.5mol / L dropwise, adjust the pH value of the solution to 6.5, and continue stirring Stop when the volume of the solution is 100ml to obtain CuMnO x Sol;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com