A system for parallel co-production of lpg by low-temperature dry distillation of coal gas to natural gas

A dry distillation technology of coal gas and natural gas, applied in the field of natural gas, can solve the problems of low methane content, waste of resources, high process cost, etc., and achieve the effects of improving thermal stability, reducing carbon load, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

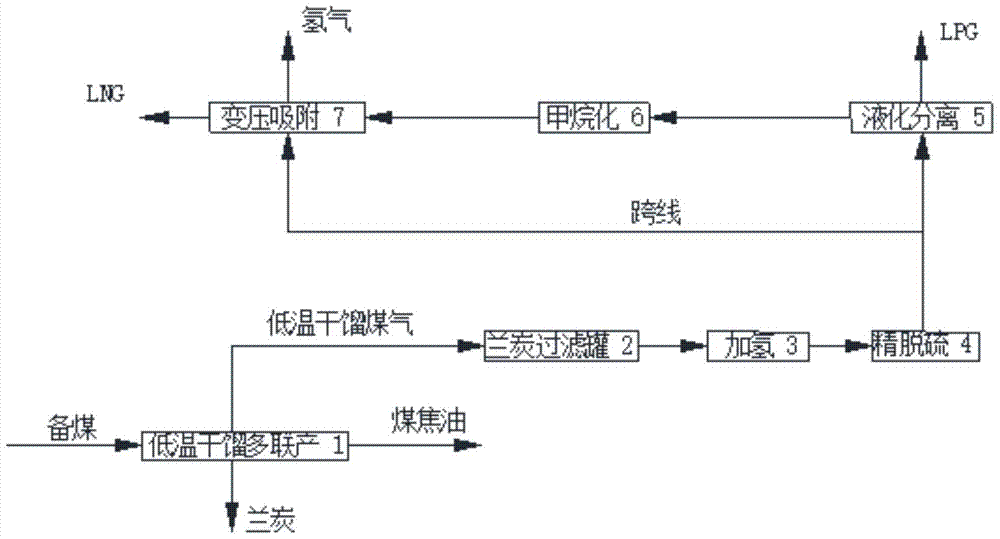

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] With reference to the accompanying drawings, a system for parallel production of LPG from low-temperature carbonization gas to natural gas comprises a low-temperature carbonization polygeneration unit 1, and the carbonization gas outlet of the low-temperature carbonization polygeneration unit 1 is connected to the gas inlet of the semi-coke filter tank unit 2, The gas outlet of the semi-coke filter tank unit 2 is connected to the gas inlet of the hydrogenation unit 3, the gas outlet of the hydrogenation unit 3 is connected to the gas inlet of the fine desulfurization unit 4, and the gas outlet of the fine desulfurization unit 4 is connected to the gas of the liquefaction separation unit 5. The inlet is connected, and a high-concentration LPG product is prepared through the liquefaction separation unit 5. The outlet of the liquefaction separation unit 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com