A kind of preparation method of antibacterial silicone rubber

A technology of silicone rubber and antibacterial agent, which is applied in the field of preparation of antibacterial silicone rubber, can solve the problems of easy change of mechanical properties of silicone rubber, short antibacterial duration, complex preparation process, etc., to protect the human body, with promising application prospects and simple process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

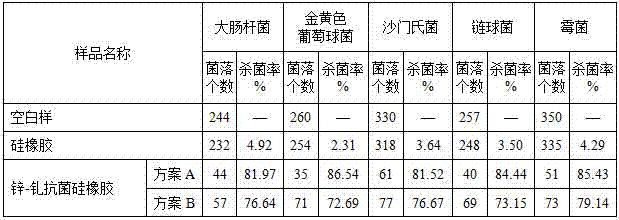

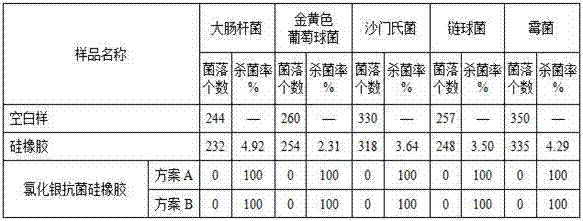

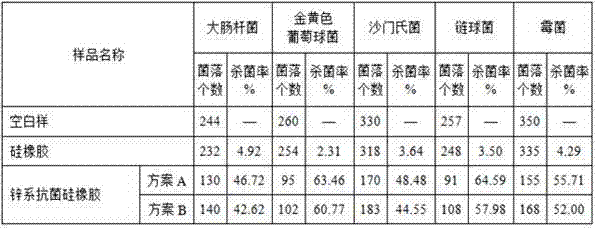

Examples

Embodiment 1

[0028] Embodiment 1: The preparation method of this zinc series antibacterial silicone rubber is as follows:

[0029] (1) Set up a constant temperature stirring reaction device (can be vacuumed), the temperature of the water bath is 90°C, preheat the water glass solution and the baking soda solution to 90°C respectively, and inject them into the reactor at a volume ratio of 1:1.25 for mixing. Fully stir the reaction at 400 rpm for 15 min, wherein the concentration of water glass solution is 15 wt%, and the concentration of baking soda solution is 10 wt%;

[0030] (2) Measure water glass solution and baking soda solution according to the volume ratio of 1:1.25, and preheat them to 90°C respectively, then pour the preheated water glass solution into step (1) under stirring condition of 150 rpm Add sodium bicarbonate solution dropwise to the reactant, react at 90°C for 15 min after the dropwise addition, adjust the pH value to 5 with sulfuric acid, then add 0.5 mol / L zinc sulfate...

Embodiment 2

[0045] Embodiment 2: the preparation method of this zinc series antibacterial silicone rubber is as follows:

[0046] (1) Set up a constant temperature stirring reaction device (can be vacuumed), the temperature of the water bath is 85°C, preheat the water glass solution and the baking soda solution to 85°C respectively, and inject them into the reactor at a ratio of 1:1.3 by volume. Fully stir the reaction at 450 rpm for 15 min, wherein the concentration of water glass solution is 12 wt%, and the concentration of baking soda solution is 9 wt%;

[0047] (2) Take the water glass solution and the baking soda solution respectively according to the volume ratio of 1:1.3, and preheat them to 85°C respectively, then pour the preheated water glass solution into step (1) under the stirring condition of 100 rpm Add sodium bicarbonate solution dropwise to the reactant, react at 85°C for 20 min after the dropwise addition, adjust the pH value to 6 with sulfuric acid, then add 0.8 mol / L z...

Embodiment 3

[0058] Embodiment 3: the preparation method of this copper series antibacterial silicone rubber is as follows:

[0059] (1) Preheat the water glass solution and the baking soda solution to 80°C respectively, inject them into the reactor at a ratio of 1:1.5 by volume and mix them, and fully stir and react at 80°C and 400 rpm for 15 minutes. The concentration of the water glass solution is 20 wt%, and the concentration of baking soda solution is 10 wt%;

[0060] (2) Take the water glass solution and the baking soda solution respectively according to the volume ratio of 1:1.5, and preheat them to 80°C respectively, and then pour the preheated water glass solution into the step (1) under the stirring condition of 200 rpm Add sodium bicarbonate solution dropwise to the reactant. After the dropwise addition, react at 80°C for 15 min, adjust the pH value to 5 with sulfuric acid, and then add 0.05 mol / L copper sulfate solution to react for 2.5 h to obtain a gel Antibacterial agent, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com