Building ground lightweight dry mixed material, and preparation and application method thereof

A dry mix and ground technology, applied in the field of building materials, can solve the problems of not being able to meet large-scale engineering construction, insufficient sources of alternative materials, and difficulty in mastering the ratio of workers, so as to achieve excellent crack resistance, save material consumption and cost, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]A method for making a ground cushion, the dosage ratio of polystyrene aggregate to powder is 1L of polystyrene aggregate: 1000g of powder; the powder is ordinary Portland cement;

[0050] Including the following steps:

[0051] (1) Ground base treatment: remove loose parts on the ground base;

[0052] (2) The design with anti-seismic pads and the ground with a one-way size greater than 5m are laid with an alkali-resistant glass fiber mesh cloth with an aperture of 10mm×10mm×80g (mass per square meter);

[0053] (3) Find the horizontal control line of the elevation elastic;

[0054] (4) Stir the powder and water into a uniform slurry with a mass ratio of about 1:0.6, then add polystyrene aggregates for secondary stirring to form a uniform mixture, and obtain a lightweight slurry for the building floor;

[0055] (5) Laying and compacting: Lay the obtained lightweight slurry on the building floor on the base layer, and use a shovel or plank to compact it as it is laid to ...

Embodiment 2

[0069] Adopt the same method as embodiment 1 to make a kind of ground cushion, difference is:

[0070] The dosage ratio of polystyrene aggregate to powder is 1L polystyrene aggregate: 800g powder; the mass ratio of ordinary Portland cement and sand in the powder is ordinary Portland cement: sand = 100:400;

[0071] The thickness of the light layer on the building ground obtained is 30 mm.

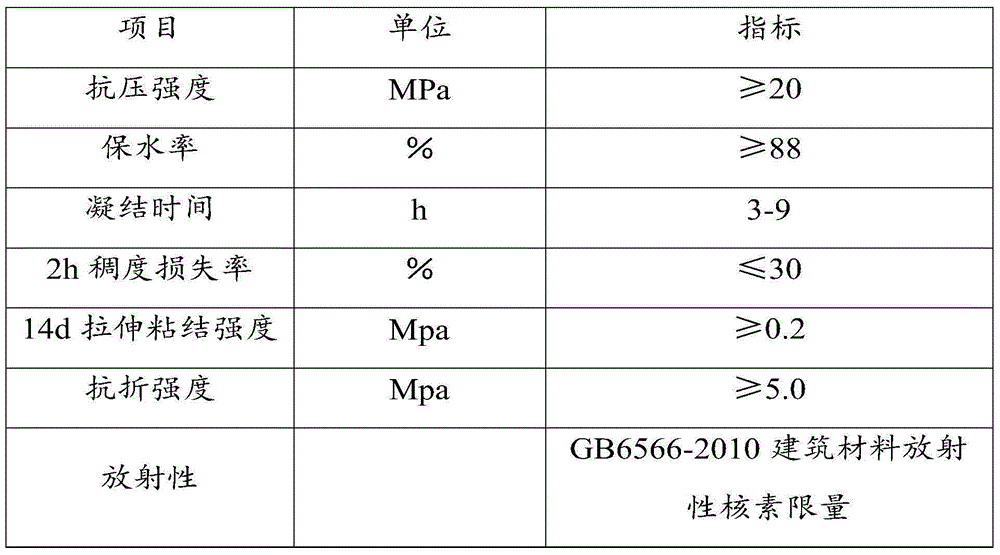

[0072] The strength, combustion performance and radioactivity of the light layer on the ground of the building obtained were tested, and the results obtained are as follows:

[0073] Table 3 The detection result of the light layer on the building ground obtained in Example 2 of the present invention

[0074] project

[0075] It can be drawn from Table 3 that the radioactivity of the light layer on the building ground obtained in Example 2 of the present invention meets the requirements of the GB6566-2010 "Limited Radionuclide Limits for Building Materials" standard, and the comb...

Embodiment 3

[0077] Adopt the same method as embodiment 1 to make a kind of ground cushion, difference is:

[0078] The dosage ratio of polystyrene aggregate to powder is 1L polystyrene aggregate: 700g powder; the mass ratio of ordinary Portland cement and S95 grade mineral powder in the powder is ordinary Portland cement: S95 grade mineral powder =100:200;

[0079] The thickness of the lightweight layer on the building ground obtained was 40 mm.

[0080] The strength, combustion performance and radioactivity of the light layer on the ground of the building obtained were tested, and the results obtained are as follows:

[0081] Table 4 The detection result of the light layer on the building ground obtained in Example 3 of the present invention

[0082] project

[0083] It can be drawn from Table 4 that the radioactivity of the lightweight layer on the building ground obtained in Example 3 of the present invention meets the requirements of the GB6566-2010 "Limited Radionuclide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com