Application of porous ion conducting membrane in lithium-sulfur battery

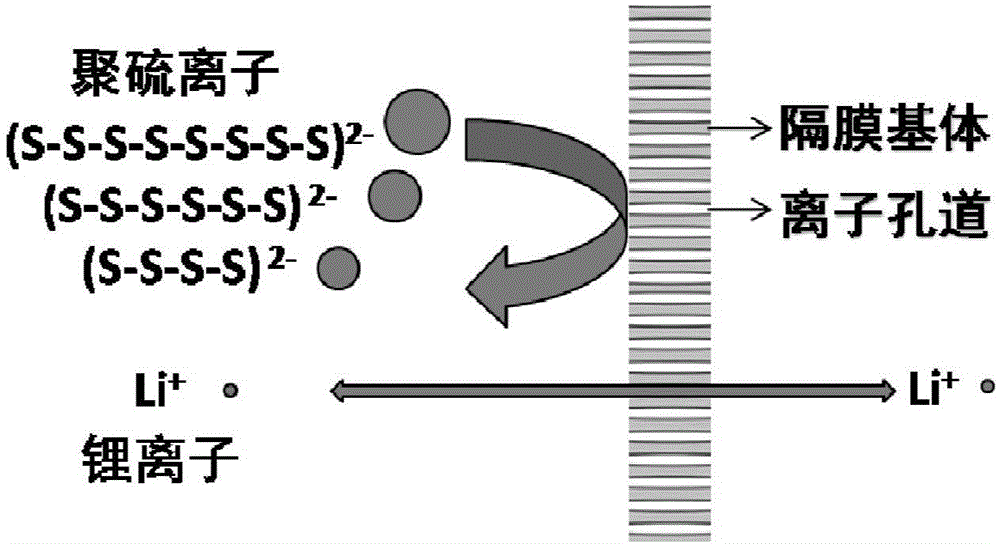

A technology of ion-conducting membranes and lithium-sulfur batteries, which is applied to battery components, circuits, electrical components, etc., can solve the problems of difficulty, limitation, and poor fluidity in the preparation of nanofiltration and below membranes, and achieve high energy conversion efficiency and Cycling stability, achieving controllability, broadening the effect of diaphragm materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

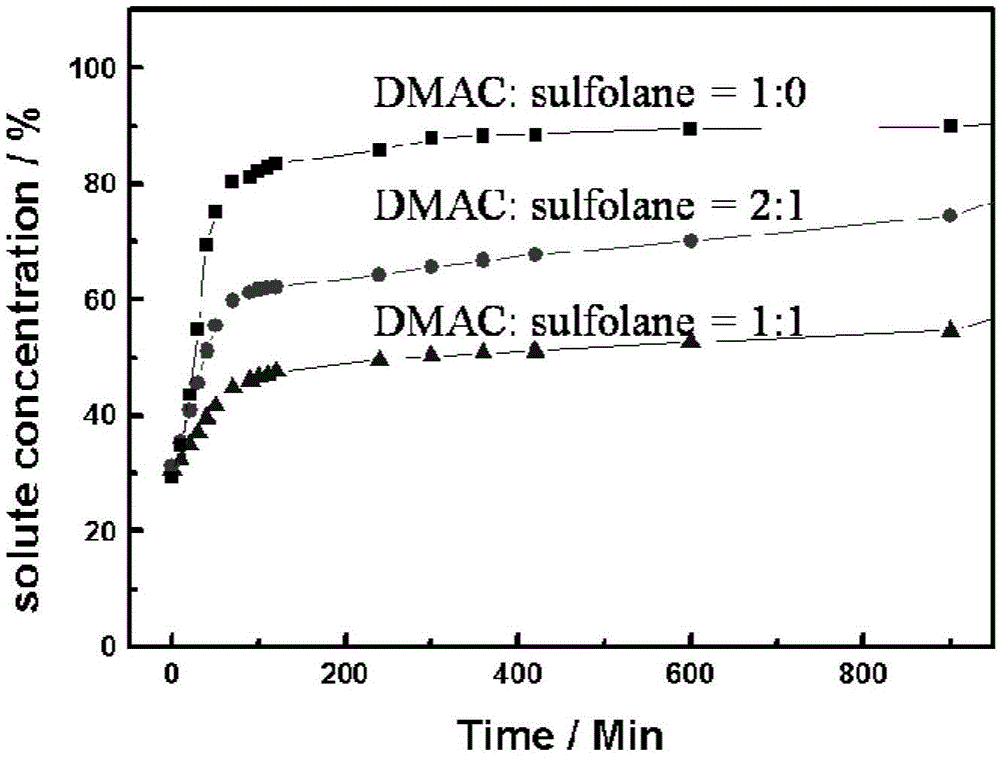

[0027] 1.8 grams of polyvinylidene fluoride with a weight average molecular weight of 50,000 was dissolved in a mixed solvent of 5 ml DMAC and 5 ml sulfolane, and stirred for 12 hours to form a polymer solution, which was spread on a glass plate to form a liquid film. Volatilize the liquid film together with the glass plate on a hot stage at 30°C for 2 hours to remove DMAC. Then the liquid membrane was quickly immersed in 5L of water, and solidified in about 1 minute to form a porous ion-conducting membrane.

[0028] The structure of the membrane is a typical asymmetric porous membrane, which is composed of a dense skin layer and a macroporous support layer. The pore diameter of the membrane skin is about 8-10nm, the porosity is 70%, and the thickness is 20 microns. The macroporous support layer is 40 microns thick, with an average pore size of 5 microns and a porosity of 80%.

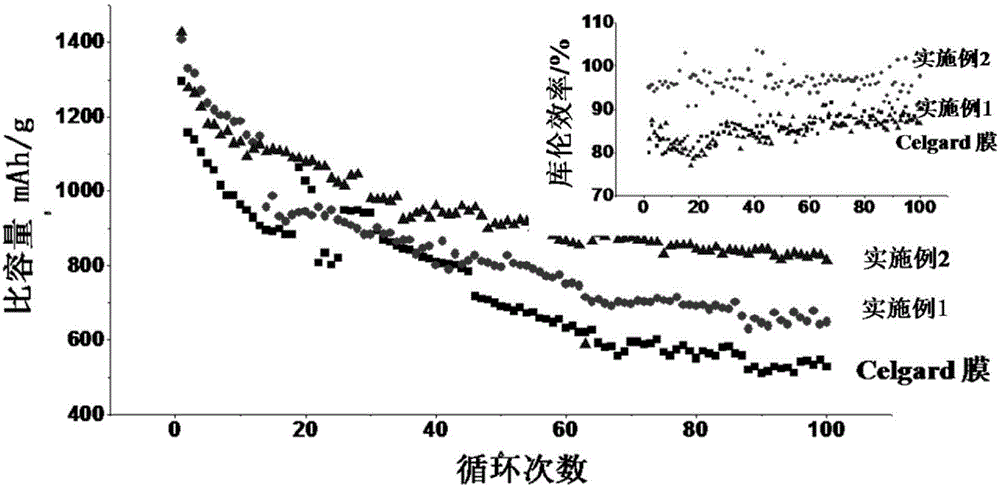

[0029] The prepared porous separation membrane was used to assemble a lithium-sulfur battery. The...

Embodiment 2

[0031] Dissolve 2.1 g of polyacrylonitrile in 3 ml of DMAC and 3 ml of sulfolane, stir for 12 hours, spread the resulting polymer solution on a glass plate to form a liquid film, and volatilize the liquid film together with the glass plate on a hot stage at 30°C for 2 hours to remove DMAC. Then quickly immersed in 5L of water to solidify to form a porous ion-conducting membrane.

[0032] The pore diameter of the membrane skin is about 40nm, the porosity is 80%, and the thickness is 60 microns.

[0033] The prepared porous separation membrane was used to assemble a lithium-sulfur battery. The commercial carbon-sulfur composite was used as the positive electrode, the metal lithium sheet was used as the negative electrode, and the tetraglyme solution of 1M lithium trifluoromethanesulfonimide was used as the electrolyte solution. The effective area is 9cm -2 , The discharge rate is 0.05C. The assembled lithium-sulfur secondary battery has a current efficiency of 98% and an energ...

Embodiment 3

[0035] Dissolve 2.3 grams of polysulfone and 0.7 grams of sulfonated polyetheretherketone in 10ml of DMAC, stir for 12 hours, spread the formed polymer solution on a glass plate, and volatilize the liquid film together with the glass plate on a hot stage at 30°C for 2 hours. DMAC. Then quickly immersed in 5L of water, solidified, forming a porous separation membrane. The pore diameter of the membrane skin is about 30nm, the porosity is 80%, and the thickness is 80 microns. The prepared porous separation membrane was used to assemble a lithium-sulfur battery. The commercial carbon-sulfur composite was used as the positive electrode, the metal lithium sheet was used as the negative electrode, and the tetraglyme solution of 1M lithium trifluoromethanesulfonimide was used as the electrolyte solution. The effective area is 9cm -2 , The discharge rate is 0.05C. The assembled lithium-sulfur secondary battery has a current efficiency of 95% and an energy efficiency of 88%. The cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com