Method and detector for detecting grouting fullness of reinforcement sleeve of prefabricated concrete structure

A concrete structure and steel sleeve technology, applied in the field of construction quality inspection, can solve problems such as inability to carry out effective inspection, and achieve the effect of fast testing speed, high precision, and efficient testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

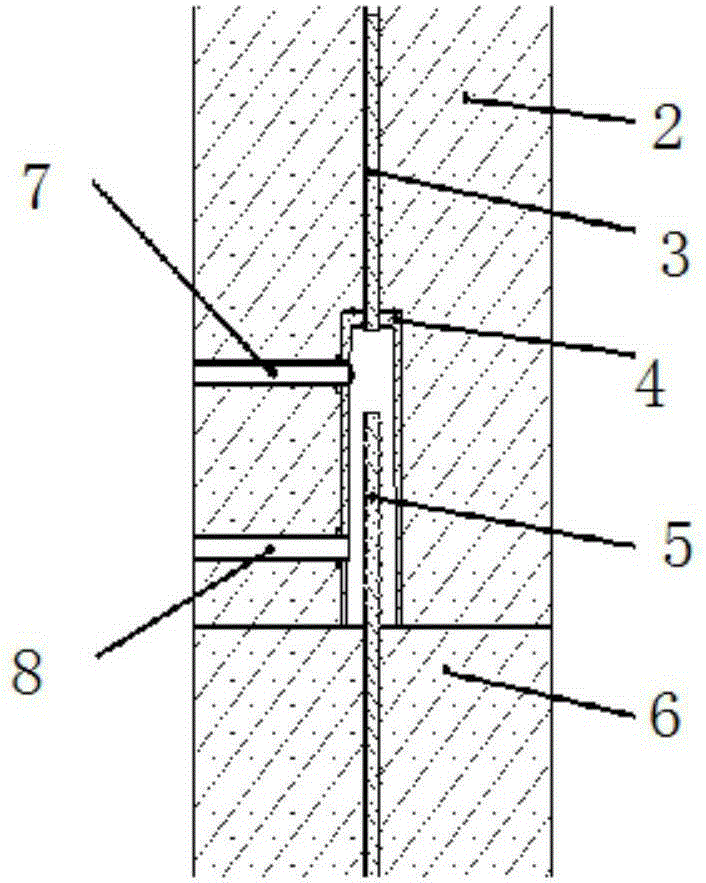

[0032] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

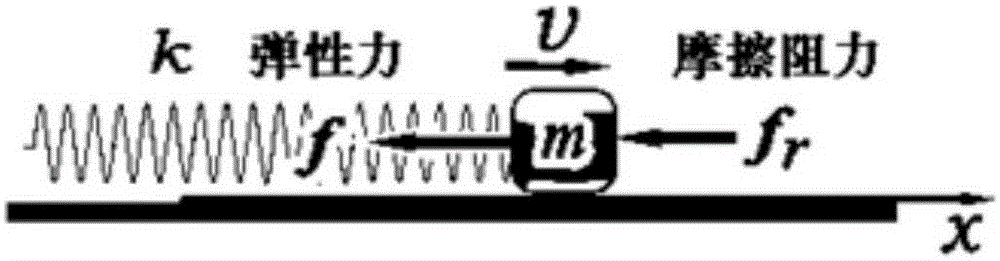

[0033] Equations available for any mechanical vibration: to represent, where x is the amplitude, A 0 is the initial amplitude, t is the time, ω is the natural angular frequency of the vibration system, and β is the damping coefficient. The amplitude of the vibration decays exponentially. When the vibration body is constant and the amplitude and frequency of the initial vibration after excitation are constant, the greater the elastic modulus of the medium around the vibration body, the greater the damping coefficient. Therefore, the medium around the vibration body is air, The damping coefficients of water, flowing mortar, and solidified mortar increase sequentially, and the corresponding amplitude attenuation will increase sharply. To this end, design a vibration sensor and a corresponding detector that can generate vibration th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com