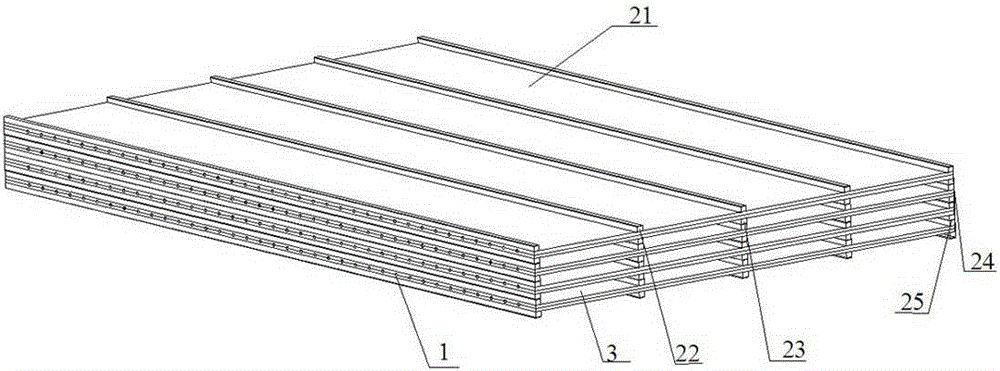

Plate type heat exchanger with gas phase and liquid phase heat exchange and resistance to high pressure

A plate heat exchanger, high-pressure resistant technology, applied in the field of gas-phase and liquid-phase heat exchange high-pressure resistant plate heat exchangers, to achieve the effect of improving heat transfer effect, improving heat transfer efficiency, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

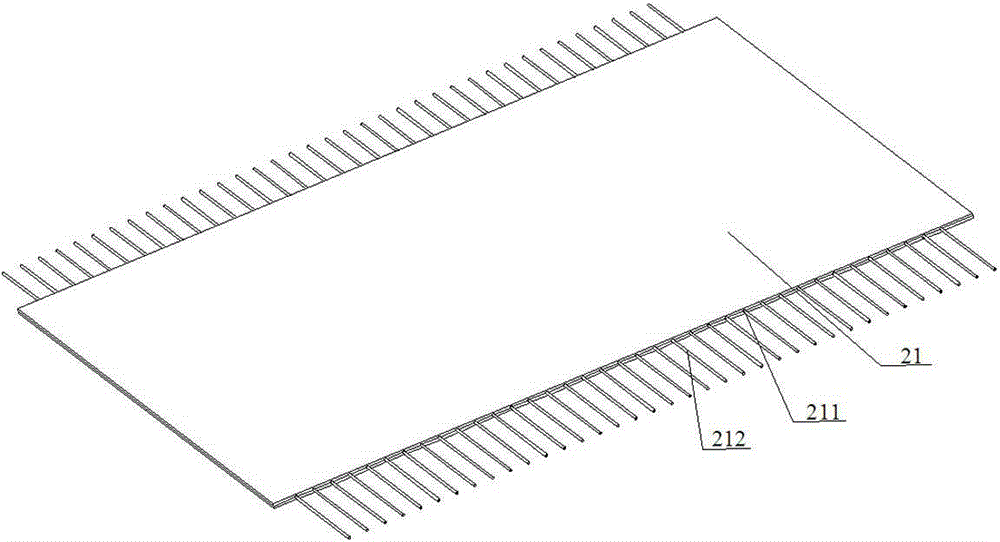

[0040] Such as figure 2 As shown, the heat exchange plate assembly 21 is composed of two non-metallic heat exchange plates, and the non-metallic heat exchange plates are provided with straight-through grooves, and the straight-through groove surfaces of the two non-metallic plates are bonded to form a channel 211 , a cooling pipe 212 is arranged in the passage to form a liquid-phase medium passage 1 . The cross section of the through groove is semicircular or rectangular.

Embodiment 2

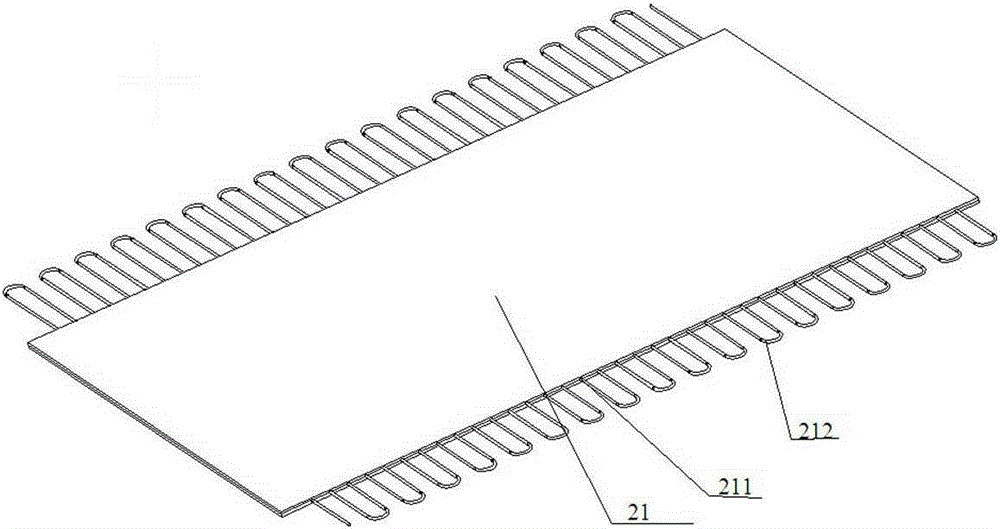

[0042] Such as image 3 As shown, the heat exchange plate assembly is composed of two non-metallic heat exchange plates, and the non-metallic heat exchange plates are provided with straight-through grooves, and the straight-through groove surfaces of the two non-metallic plates are bonded to form a channel 211 , a serpentine cooling pipe 212 is arranged in the passage to form a liquid medium passage 1 .

Embodiment 3

[0044] Such as Figure 4 As shown, the heat exchange plate assembly is composed of two non-metal heat exchange plates sandwiching a metal heat exchange plate, the non-metal heat exchange plate and the metal heat exchange plate are bonded, and the metal heat exchange plate is equipped with channel (such as Figure 5 shown), which is the liquid medium channel 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com