Vapor mixing device reducing NOx emission

A technology of mixing device and mist, which is applied in the transportation of non-flammable liquid/gas, combustion method, combustion equipment, etc., can solve the problems of difficulty in reducing NOx emission, high maintenance cost, and difficulty in meeting requirements, and achieves reduction of reaction probability, Simple structure and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

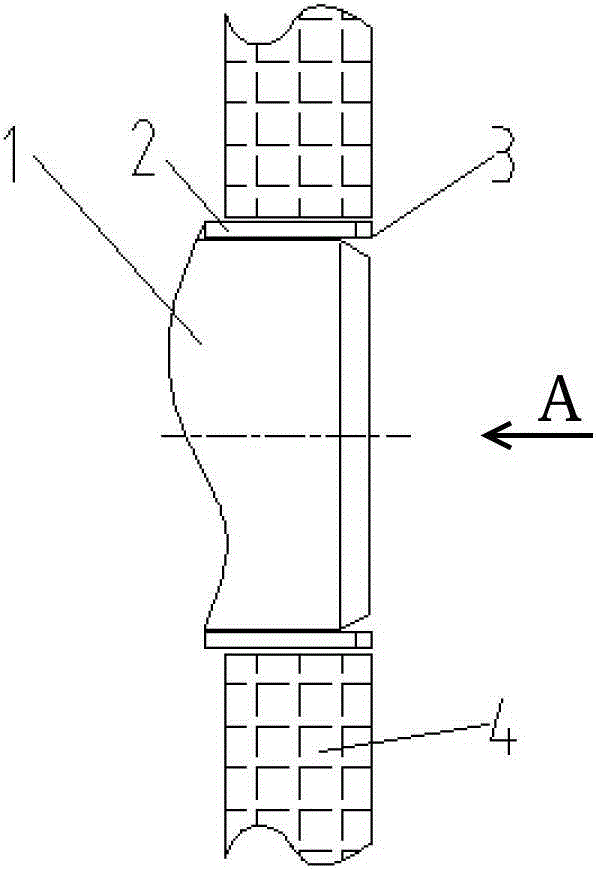

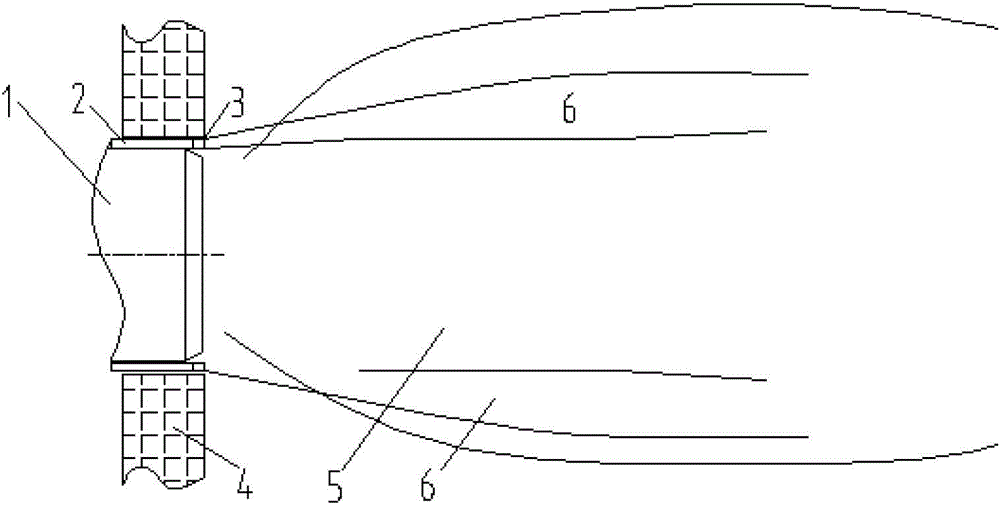

[0015] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 A schematic diagram of the structure. It can be seen from the figure that the mist-steam mixing device for reducing NOx emissions includes a burner throat and a furnace combustion chamber. The spray gun 2 is arranged in the same direction and parallel to the axis of the burner throat 1, and the end of the spray gun 2 facing the furnace combustion chamber is equipped with a spray gun head 3. The tail end of the spray gun 2 is connected to the high-pressure water / steam pipeline .

[0016] The number of the spray guns 2 is 3-20, which are evenly distributed along the outer periphery of the burner throat 1 .

[0017] When the pipeline connected to the tail end of the spray gun 2 is high-pressure water, the corresponding spray gun head 3 is a mechanical atomizing head.

[0018] When the pipes connected at the ends of the spray guns 2 contain steam, the corresponding spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com