Novel far-infrared cotton fiber suitable for infants and children and preparation method of novel far-infrared cotton fiber

A far-infrared cotton and cotton fiber technology, applied in fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problems of fabric safety and comfort, improve anti-wrinkle and anti-shrink performance, wash resistance and durability , the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

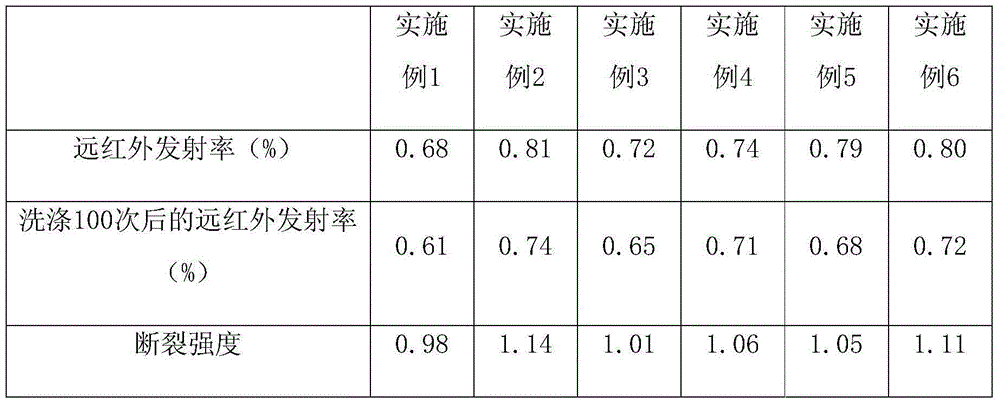

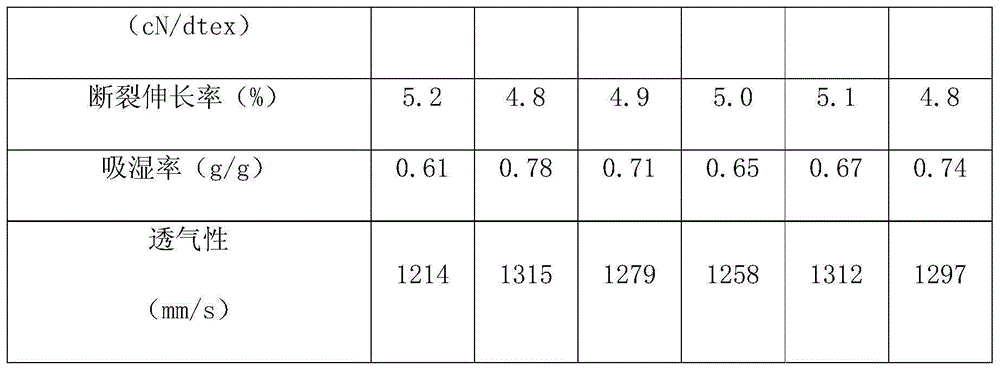

Examples

Embodiment 1

[0028] (1) Add 0.5% papain to the sericin solution with a pH value of 8 obtained after silk degumming, react at 10° C. for 1 hour, take it out and freeze-dry to obtain a sericin polypeptide hydrolyzate with a molecular weight of 2000 Da.

[0029] (2) Place the cotton fiber in a gaseous nitrogen dioxide environment to oxidize the primary hydroxyl groups of the cotton fiber in the dark for 30 minutes, take it out and leave it in a vacuum to obtain the oxidized cotton fiber.

[0030] (3) In parts by weight, dissolve 25 parts of sericin polypeptide hydrolyzate prepared in step (1) in 40 parts of deionized water, stir, add 10 parts of 500nm nano-ceramic powder and 20 parts of seaweed Na2SO4, stirred evenly to obtain the far-infrared treatment liquid containing sericin.

[0031] (4) Place the oxidized cotton fiber prepared in step (2) in the far-infrared treatment solution containing sericin prepared in step (3) with a liquor ratio of 1:20, dip and shake at 50°C for 60min, take it o...

Embodiment 2

[0033] (1) Add 1% serine protease to the sericin solution with a pH value of 9 obtained after silk degumming, react at 20° C. for 2 hours, take it out and freeze-dry to obtain a sericin polypeptide hydrolyzate with a molecular weight of 1200 Da.

[0034] (2) Place the cotton fiber in a gaseous nitrogen dioxide environment to oxidize the primary hydroxyl groups of the cotton fiber in the dark for 40 minutes, take it out and leave it in a vacuum to obtain the oxidized cotton fiber.

[0035] (3) In parts by weight, 35 parts of sericin polypeptide hydrolyzate prepared in step (1) were dissolved in 60 parts of deionized, stirred, and 15 parts of 800nm nano-ceramic powder and 40 parts of seaweed were added Na2SO4, stirred evenly to obtain the far-infrared treatment liquid containing sericin.

[0036] (4) Place the oxidized cotton fiber prepared in step (2) in the far-infrared treatment solution containing sericin prepared in step (3) with a bath ratio of 1:30, dip and shake at 60°...

Embodiment 3

[0038] (1) Add 0.7% papain to the sericin solution with a pH value of 8.5 obtained after silk degumming, react at 15° C. for 1.5 h, take it out and freeze-dry to obtain a sericin polypeptide hydrolyzate with a molecular weight of 1600 Da.

[0039] (2) Place the cotton fiber in a gaseous nitrogen dioxide environment to oxidize the primary hydroxyl groups of the cotton fiber in the dark for 35 minutes, take it out and leave it in a vacuum to obtain the oxidized cotton fiber.

[0040] (3) In parts by weight, dissolve 30 parts of sericin polypeptide hydrolyzate prepared in step (1) in 50 parts of deionized water, stir, add 12 parts of 600nm nano-ceramic powder and 30 parts of seaweed Na2SO4, stirred evenly to obtain the far-infrared treatment liquid containing sericin.

[0041] (4) Place the oxidized cotton fiber prepared in step (2) in the far-infrared treatment solution containing sericin prepared in step (3) with a bath ratio of 1:25, dip and shake at 55°C for 80min, take it out,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com