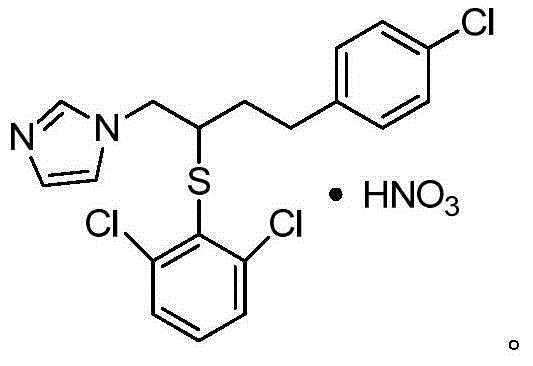

Method for industrial process production of butoconazole nitrate

A technology of butoconazole nitrate and imidazole, which is applied in the field of production technology of butoconazole nitrate, can solve the problems of complex post-processing steps, lack of impurities, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

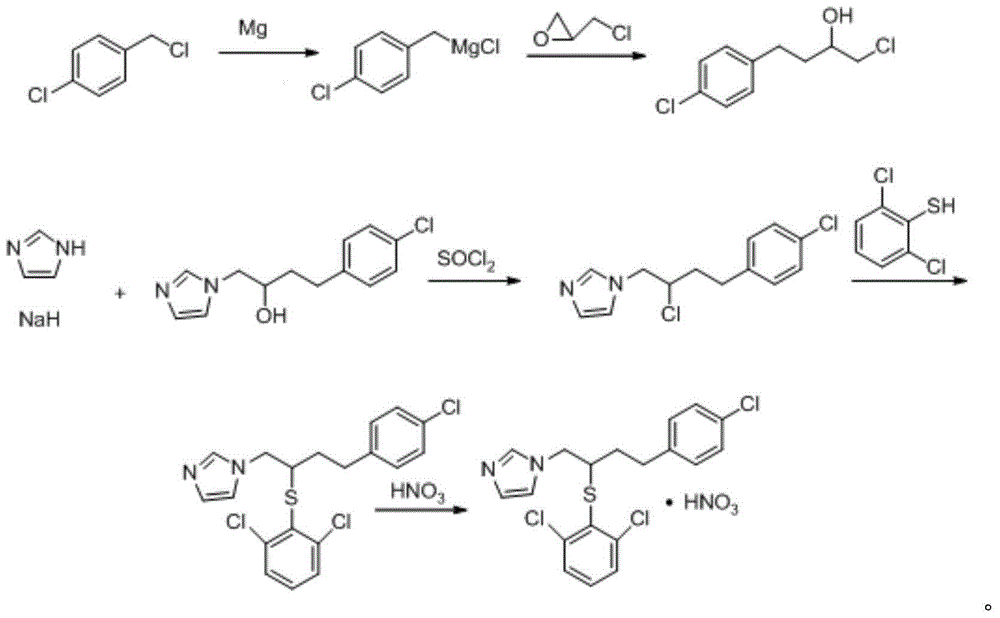

Method used

Image

Examples

Embodiment 1

[0053] Butoconazole nitrate is produced according to the following sequential steps:

[0054] (1) Get 2kg of magnesium powder, 50ml of ether and a catalytic amount of iodine, add 40kg of p-chlorobenzyl ether solution with a concentration of 0.27g / ml dropwise at a rate of 3ml / s at 35°C, and after the dripping, place the solution at 37°C React for 1 hour to obtain p-chlorobenzyl Grignard reagent; then slowly add 20 kg of epichlorohydrin ether solution with a concentration of 0.35 g / ml dropwise, and react at 37°C for 1.5 hours to obtain a reaction solution; 1. Under the condition of constant speed stirring, in the reaction solution, drip the sulfuric acid with a concentration of 25% at a speed of 2ml / s, and stop the dripping when there is no solid residue; leave standstill for 10 minutes after stirring at a constant speed for 10 minutes to make the liquid layer; discard the water phase, take the organic phase and concentrate it under the conditions of -0.01MPa and 55°C until no d...

Embodiment 2

[0061] Butoconazole nitrate is produced according to the following sequential steps:

[0062] (1) get 1.5kg magnesium powder, the iodine of the diethyl ether of initiation amount and catalytic amount, the mass volume ratio of described magnesium powder and initiation diethyl ether is 1.5kg / 50ml; Drop 35kg with the speed of 2ml / s at 30 ℃ Concentration of 0.25g / ml p-chlorobenzyl ethyl ether solution, react at 35°C for 0.5 hours after dropping to get p-chlorobenzyl Grignard reagent; then slowly add 15 parts of epoxy chloride with a concentration of 0.33g / ml Propane ether solution, react at 35 DEG C for 1 hour after dropping, to obtain the reaction liquid; in the described reaction liquid, drip the sulfuric acid with a concentration of 24% at a speed of 1 ml / s at 0 DEG C and uniform stirring condition, until no When the solid remains, stop the dropwise addition; stir at a constant speed for 5 minutes and then let stand for 8 minutes to separate the liquid; discard the water phase,...

Embodiment 3

[0070] Butoconazole nitrate is produced according to the following sequential steps:

[0071] (1) get 2.5kg magnesium powder, the iodine of the diethyl ether of initiation amount and catalytic amount, the mass volume ratio of described magnesium powder and initiation diethyl ether is 2.5kg / 50ml; Drop 45kg with the speed of 4ml / s at 40 ℃ Concentration of 0.25 ~ 0.3g / ml p-chlorobenzyl ethyl ether solution, react at 40°C for 1.5 hours after dropping to get p-chlorobenzyl Grignard reagent; then slowly add 25 kg of 0.33 ~ 0.37g / ml Epichlorohydrin ether solution, react at 40°C for 2 hours after dropping, to obtain a reaction solution; add sulfuric acid with a concentration of 26% to the reaction solution at a rate of 3ml / s at 10°C under constant stirring , stop dropping when there is no solid residue; stir at a constant speed for 15 minutes and let stand for 12 minutes to separate the liquid; discard the water phase, take the organic phase and concentrate it at 0MPa and 60°C until n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com