A translational titanium gypsum calcination equipment

A titanium gypsum, translational technology, applied in the field of translational titanium gypsum calcining equipment, can solve the problems of low product quality, air pollution, and high maintenance costs, achieve uniform humidity inside and outside, improve product quality, and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

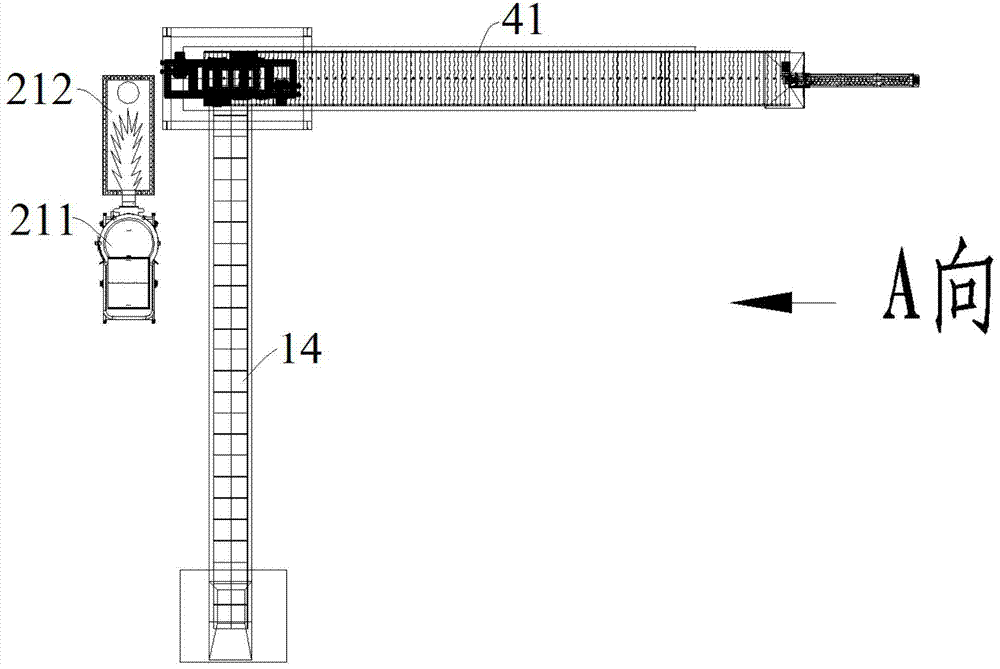

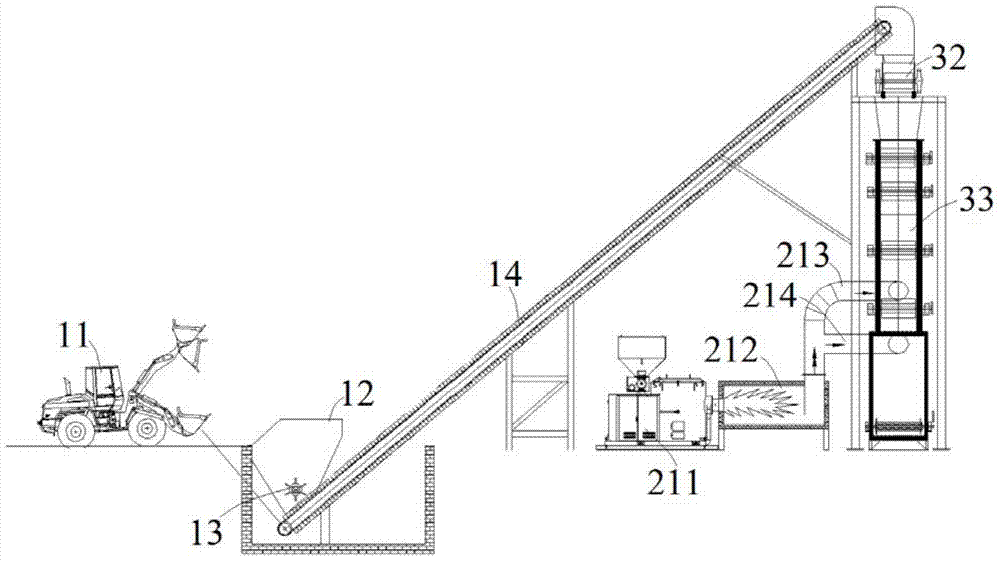

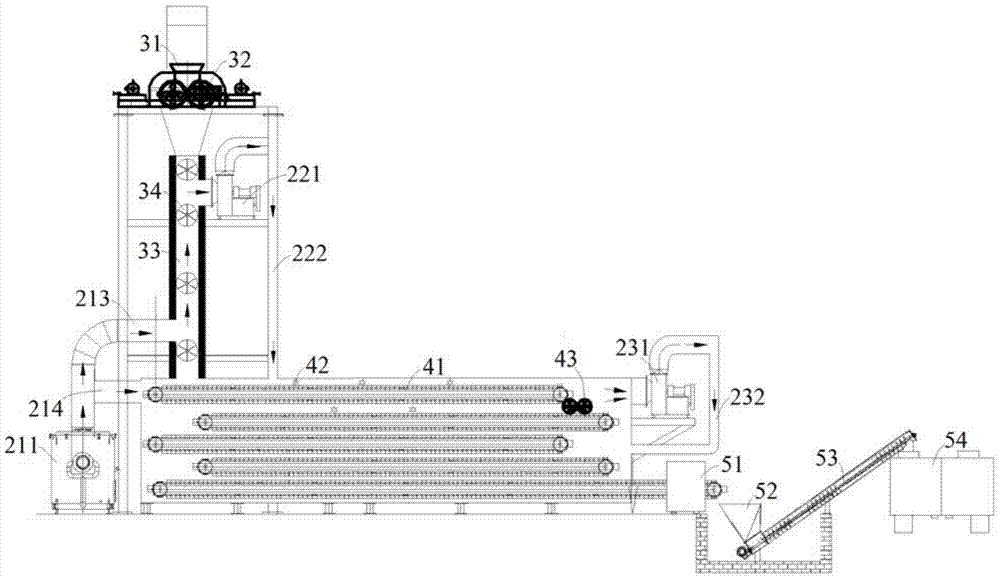

[0039] see figure 1 , figure 2 and image 3 , a translational titanium gypsum calcination device in this embodiment, including a feeding mechanism, a high-temperature calcination mechanism, a translational drying mechanism, a hot air circulation supply mechanism, and a discharging mechanism.

[0040] Wherein, the feeding mechanism includes a feeding cart 11, a feeding bin 12, a feeding breaker 13 and a feeding belt 14, the feeding belt 14 is arranged obliquely, and one end of the feeding belt 14 is aligned with the discharge of the feeding bin 12. The other end of the feeding belt 14 is arranged directly above the feeding port 31 of the high temperature calcination mechanism. The feeding truck 11 pours the titanium gypsum with high water content and high viscosity into the feeding bin 12, then falls onto the feeding belt 14, and is sent into the high-temperature calcination mechanism by the feeding belt 14. In view of the very high viscosity of the raw material titanium gy...

Embodiment 2

[0055] A kind of translational titanium gypsum calcining equipment of this embodiment is basically the same as that of Embodiment 1, the difference is that: three air lock feeders 34 of this embodiment are arranged along the length direction of the high-temperature pipeline 33, and they are translated and dried The mechanism is provided with 4 layers of translation conveyor belts 41 along the vertical direction.

Embodiment 3

[0057] A kind of translational titanium gypsum calcining equipment of this embodiment is basically the same as that of Embodiment 1, and its difference is that: the air lock feeder 34 of this embodiment is provided with 5 along the length direction of high-temperature pipeline 33, and translational drying The mechanism is provided with 6 layers of translation conveyor belts 41 along the vertical direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com