Hydraulic Control Main Valve for Energy Regeneration

A hydraulic and energy technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as piston stalling and falling, cylinder rod chamber insufficient oil supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

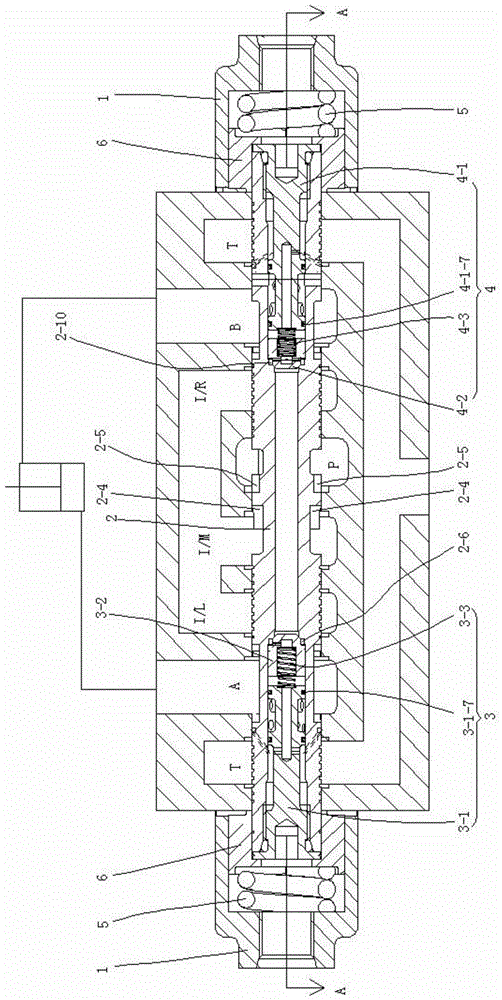

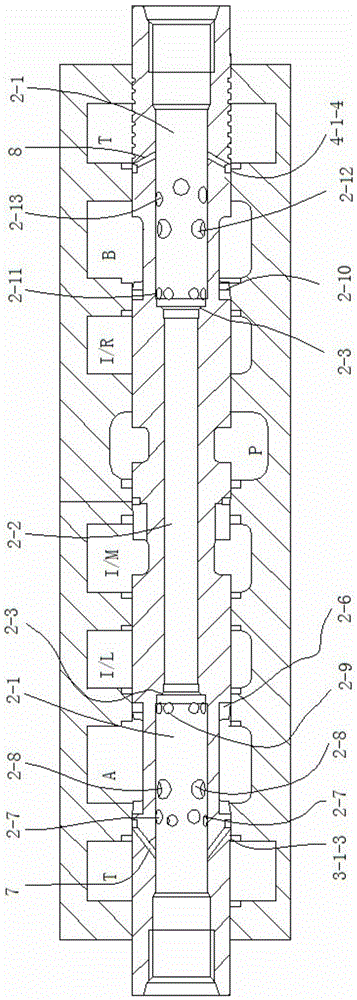

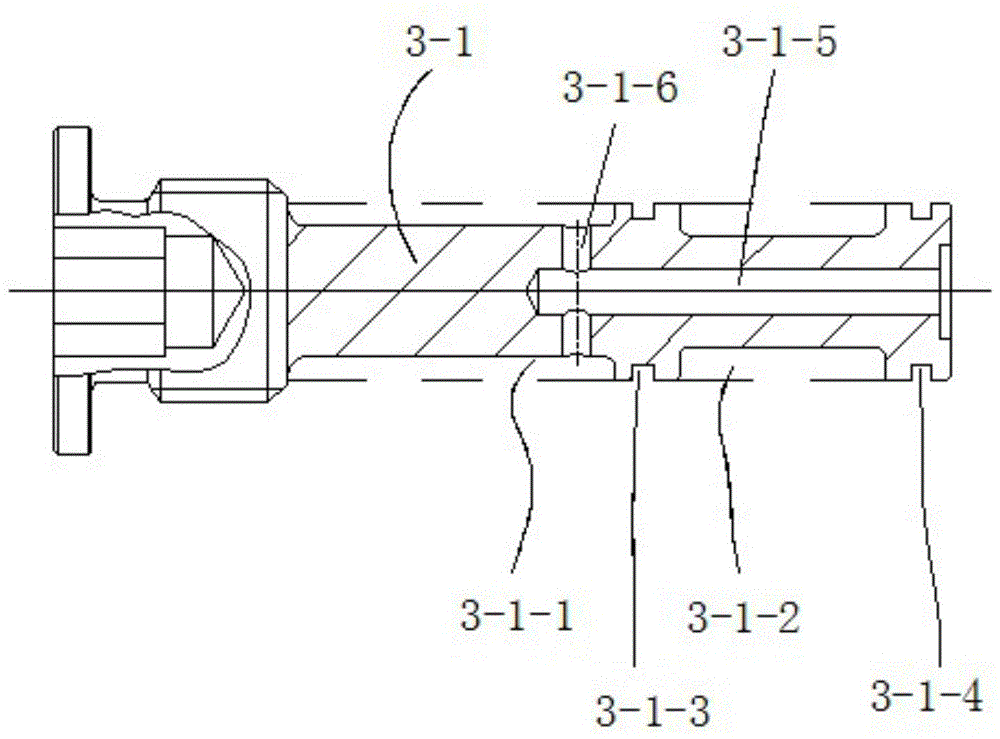

[0023] See figure 1 , a hydraulically controlled main valve for energy regeneration and utilization, has an end cover 1, a valve core 2, a left check valve 3 and a right check valve 4; There are left oil port T, oil port A, oil port I / L, oil port I / M, oil port I / R, oil port B, right oil port T and oil port P; There are springs 5 and spring seats 6 between them; the left and right ends of the valve core 2 are respectively embedded with a left check valve 3 and a right check valve 4; the left check valve 3 is composed of a left valve seat 3-1, a left cone valve core 3-2 and the left spring 3-3; the conical surface of the left cone spool 3-2 is closely attached to the left conical surface of the spool 2 through the action of the left spring 3-3; the right one-way valve 4 is formed by the right valve seat 4-1, right cone spool 4-2 and right spring 4-3 are formed; the cone surface of right cone spool 4-2 is close to the right cone surface of spool 2 by the effect of right spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com