Mechanical dust removal device capable of separating out impurities conveniently for seed processing

A mechanical dust removal and seed technology, applied in grain processing and other directions, can solve the problems of low work efficiency, insufficient vibration and dust removal of seeds, and fast falling speed of seeds, so as to achieve complete and comprehensive dust removal effect and improve removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

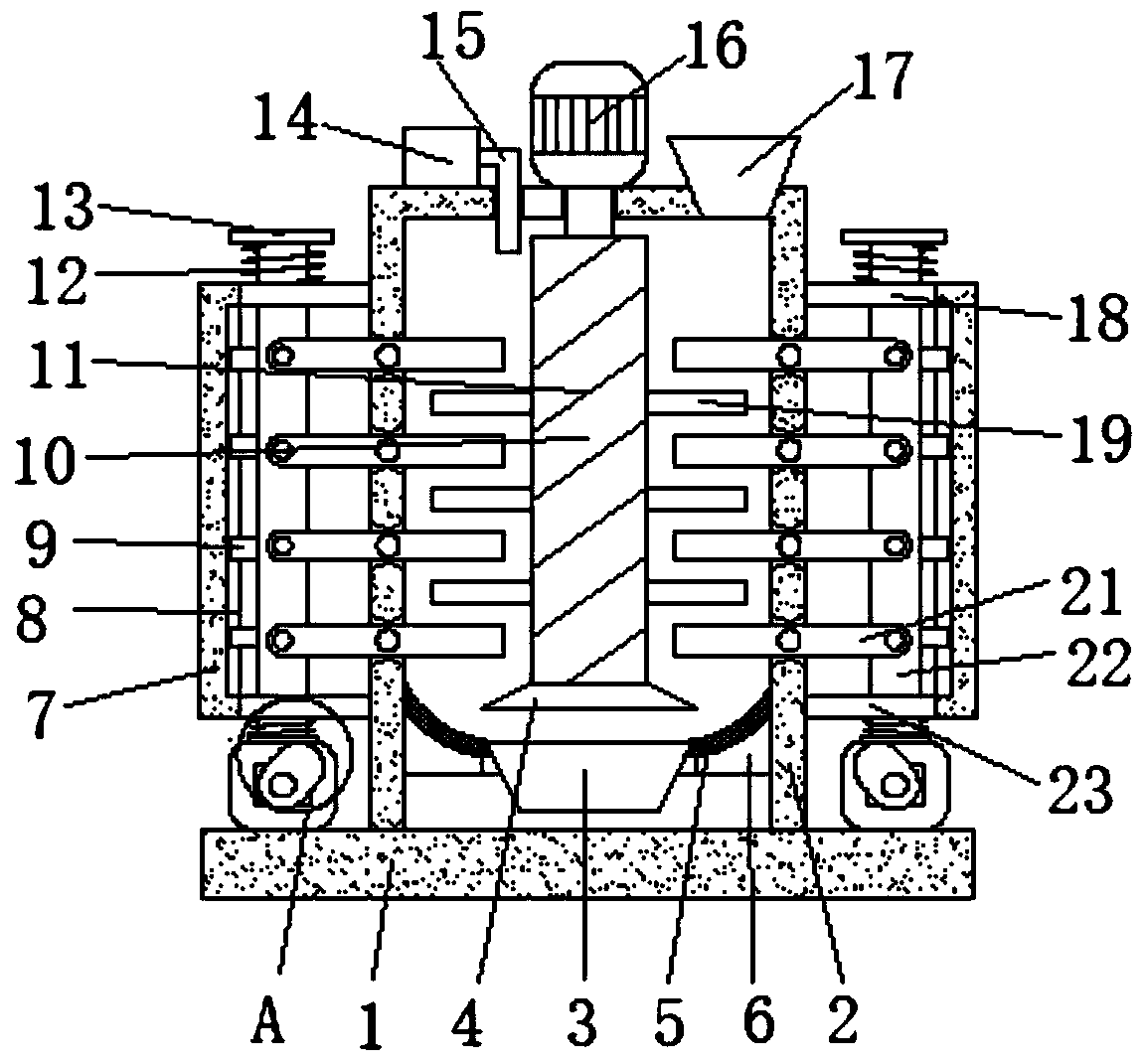

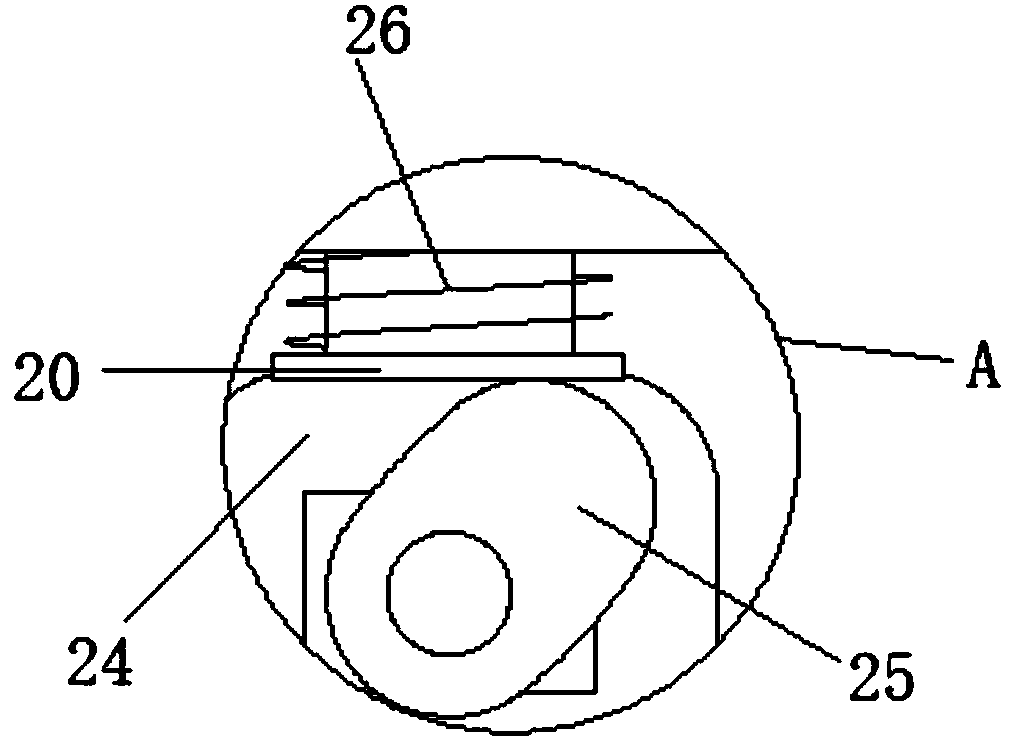

[0018] Reference Figure 1-2 , A mechanical dust removal device for seed processing that facilitates the separation of impurities, comprising a bottom plate 1, the upper end of the bottom plate 1 is provided with a casing 2, and the upper end of the casing 2 is respectively provided with a suction fan 14, a first motor 16 and a feed pipe 17, A suction pipe 15 is connected to the suction fan 14. The suction pipe 15 penetrates the outer wall of the housing 1 and extends into the inner cavity. The output shaft of the first motor 16 penetrates the outer wall of the housing 1 and extends into the inner cavity and is connected with a long shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com