Clean production method of hydrocalumite

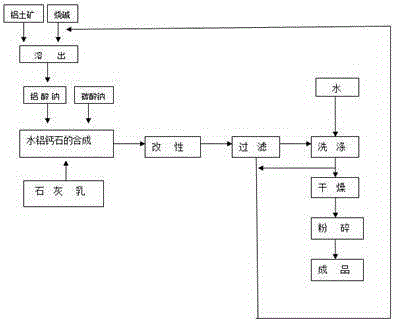

A clean production and hydrocalumite technology, which is applied in the field of fine chemicals, can solve the problems of high cost, production scale and application impact, increase the production cost of hydrocalumite, etc., achieve low production costs, avoid waste water and other pollution, and prepare short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

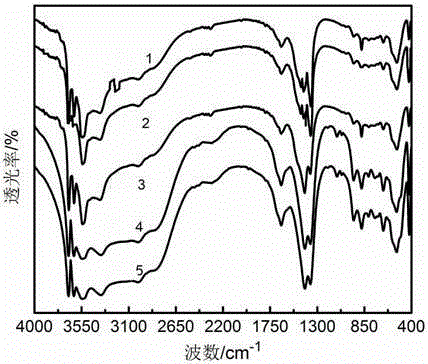

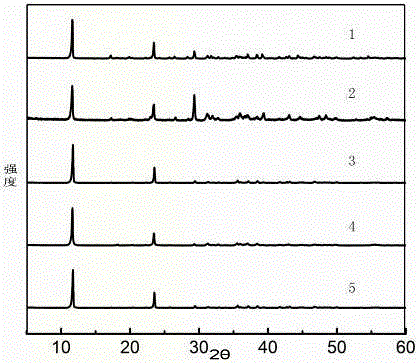

Embodiment 1

[0018] Example 1: Bauxite is pulverized, and caustic soda (NaOH) solution is added to dissolve alumina in bauxite under high temperature and high pressure to obtain crude sodium aluminate solution. Then further purify, filter and concentrate to obtain a saturated solution of sodium aluminate. Weigh Ca(OH) according to the ratio of substance ratio of 4:2:1 2 , NaAlO 2 and Na 2 CO 3 , placed in the reactor, and excess deionized water was added to the reactor. After continuous stirring at room temperature, in an autoclave at 90 o C and keep it warm for 12 hours to age and grow crystals of the product. After taking out and cooling down to room temperature, the supernatant was poured off, the product obtained was rinsed with deionized water to neutrality and suction filtered, and the filter cake was placed at 60 o C dried in a vacuum oven to obtain solid hydrocalumite sample 1.

Embodiment 2

[0019] Embodiment 2: Bauxite is pulverized, and caustic soda (NaOH) solution is added to dissolve alumina in bauxite under high temperature and high pressure to obtain crude sodium aluminate solution. Then further purify, filter and concentrate to obtain a saturated solution of sodium aluminate. Weigh Ca(OH) according to the ratio of substance ratio of 3.5:2:1 2 , NaAlO 2 and Na 2 CO 3 , placed in the reactor, and excess deionized water was added to the reactor. After continuing to stir at room temperature for 5h, transfer to 160 o C aging in a high-pressure reactor for 6 hours to age and grow crystals of the product. After taking out and cooling down to room temperature, the supernatant was poured off, the product obtained was rinsed with deionized water to neutrality and suction filtered, and the filter cake was placed at 60 o C dried in a vacuum oven to obtain solid hydrocalumite sample 2.

Embodiment 3

[0020] Embodiment 3: Bauxite is pulverized, and caustic soda (NaOH) solution is added to dissolve alumina in bauxite under high temperature and high pressure to obtain crude sodium aluminate solution. Then further purify, filter and concentrate to obtain a saturated solution of sodium aluminate. Weigh Ca(OH) according to the ratio of substance ratio of 5:3:1 2 , NaAlO 2 and Na 2 CO 3 , placed in the reactor, and excess deionized water was added to the reactor. After continuous stirring at room temperature for 20h, transfer to 160 o C aging in a high-pressure reactor for 6 hours to age and grow crystals of the product. After taking out and cooling down to room temperature, the supernatant was poured off, the product obtained was rinsed with deionized water to neutrality and suction filtered, and the filter cake was placed at 60 o C dried in a vacuum oven to obtain solid hydrocalumite sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com