Preparation method of N-doped SiC nanoneedle flexible field emission cathode material

A field emission cathode and nanoneedle technology, which is applied in the preparation of SiC flexible field emission cathode materials and the preparation field of N-doped SiC nanoneedle flexible field emission cathode materials, can solve the problem that no atomic-doped SiC nanostructure flexible cathode materials are disclosed. preparation and other issues to achieve the effect of stabilizing the electron emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

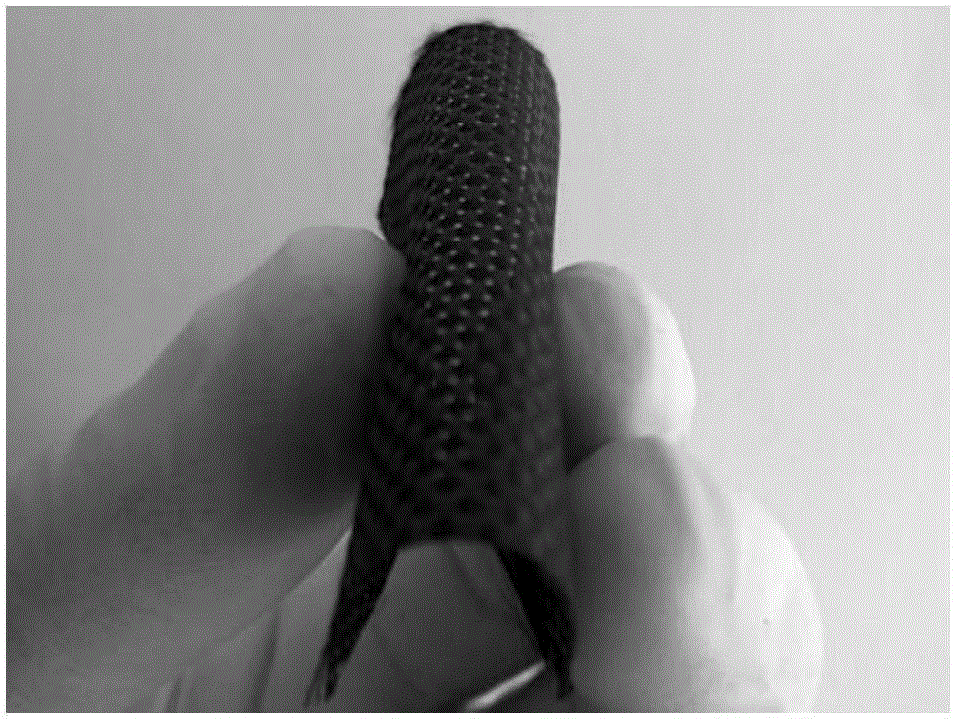

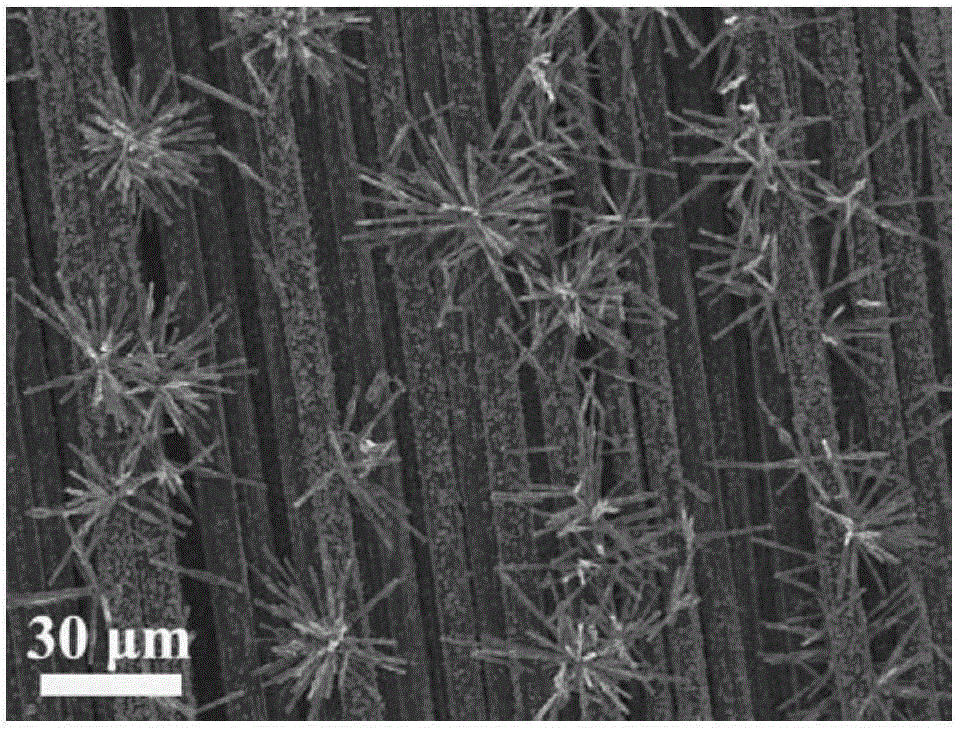

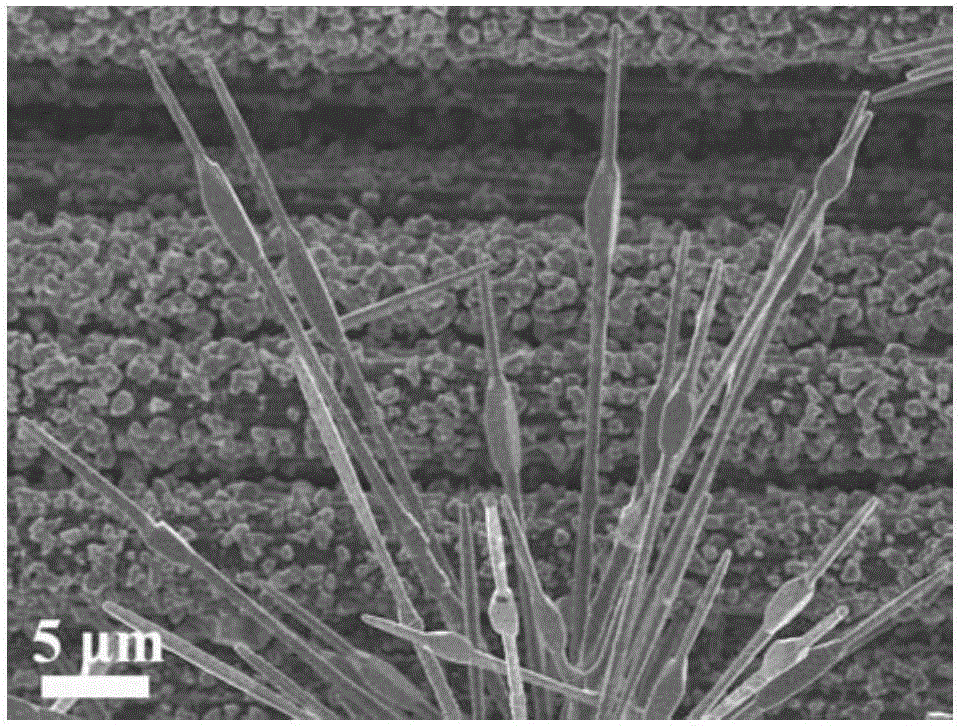

Embodiment 1

[0034] The initial raw material is polysilazane, in N 2 Under the protection of the atmosphere, heat preservation at 260°C for 30 minutes for thermal crosslinking and curing. Put the solidified SiCN solid into a nylon resin ball mill tank, and ball mill it into powder. Weigh 300 mg of polysilazane powder and place it at the bottom of the graphite crucible container. Cut carbon fiber cloth 5×5cm (length×width), and spray a layer of 10nm thick Au film on its surface as a catalyst. Arrange the Au-sprayed carbon fiber on the top of the graphite crucible container, and place it in an atmosphere sintering furnace heated by graphite resistance. The atmosphere furnace is first evacuated to 10 -4 Pa, refill N 2 :Ar=5:95 mixed gas (purity is 99.99%), until the pressure is one atmosphere (~0.11Mpa), and then the pressure is constant. Then heat up rapidly from room temperature to 1750°C at a rate of 30°C / min for pyrolysis, then cool down to 1100°C at a rate of 16°C / min, and finally c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com