Sintered neodymium-iron-boron magnet and preparing method thereof

A technology of NdFeB magnets, which is applied in the direction of magnetic objects, inductors/transformers/magnet manufacturing, magnetic materials, etc., can solve the problems of reduced magnetic properties of sintered NdFeB magnets, save preparation costs, solve stacking problems, reduce The effect of performance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

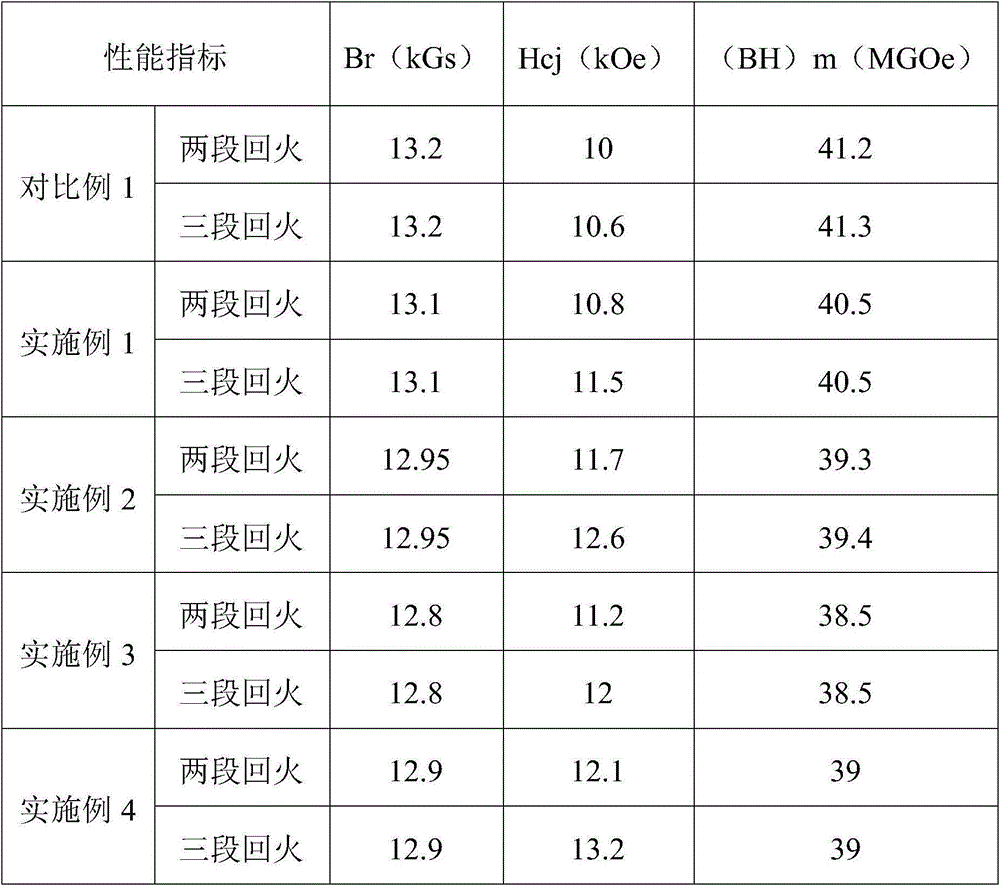

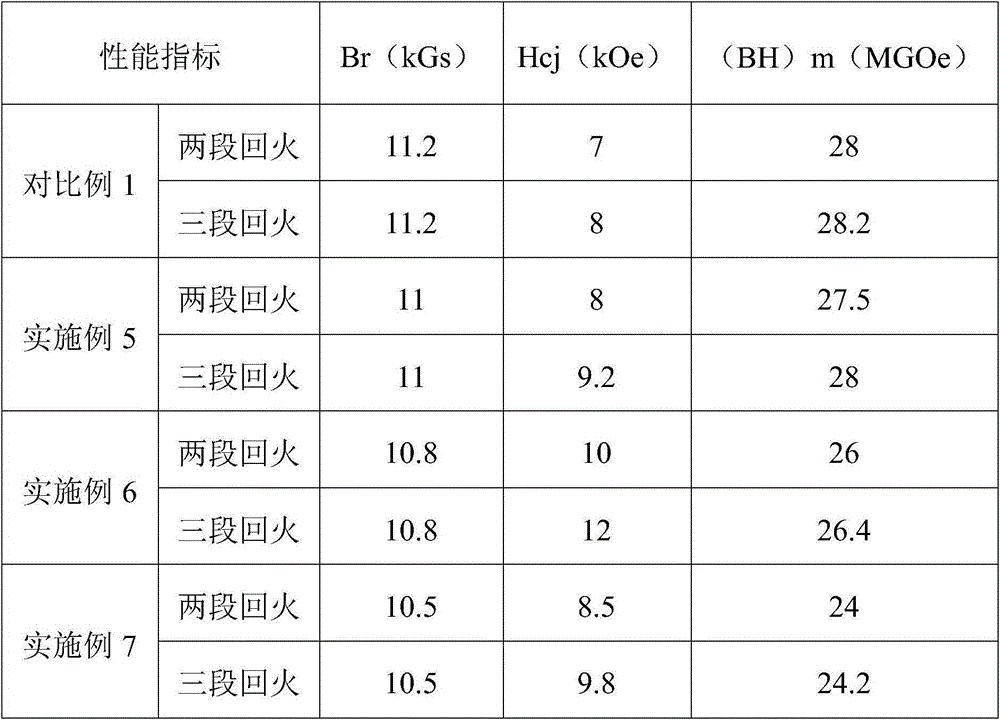

Embodiment 1

[0023] Supplementary phase CeH y It is directly obtained by crushing pure cerium metal with hydrogen absorption and jet milling, and the average particle size of the powder is 1.5 μm. 1wt% CeH y Incorporation (Ce 0.2 Nd 0.8 ) 31 Fe 67.7 al 0.1 Cu 0.1 Zr 0.1 B Jet mill powder, mixed evenly, oriented in a magnetic field to form a rough magnet, put it into a vacuum sintering furnace for sintering at 1020°C, 880°C + 500°C two-stage tempering treatment; and sintering at 1020°C, 880°C ℃+500℃+350℃ three-stage tempering treatment to prepare sintered NdFeB magnets, the magnetic properties are shown in Table 1.

Embodiment 2

[0025] Auxiliary phase PrNdH y It is directly obtained by hydrogen absorption crushing of praseodymium and neodymium metal, and jet milling powder, with an average particle size of 1.5 μm. 2wt% PrNdH y Incorporation (Ce 0.2 Nd 0.8 ) 31 Fe 67.7 al 0.1 Cu 0.1 Zr 0.1 B Jet mill powder, mixed evenly, oriented in a magnetic field to form a rough magnet, placed in a vacuum sintering furnace for sintering at 1010°C, 860°C+490°C two-stage tempering treatment; and sintering at 1010°C, 860°C ℃+490℃+320℃ three-stage tempering treatment to prepare sintered NdFeB magnets, the magnetic properties are shown in Table 1.

Embodiment 3

[0027] Supplementary phase CeH y It is directly obtained by crushing pure cerium metal with hydrogen absorption and jet milling, and the average particle size of the powder is 1.5 μm. 3wt% CeH y Incorporation (Ce 0.2 Nd 0.8 ) 31 Fe 67.7 al 0.1 Cu 0.1 Zr 0.1 B Jet mill powder, mixed evenly, oriented in a magnetic field to form a rough magnet, put it into a vacuum sintering furnace for sintering at 980°C, 850°C + 480°C two-stage tempering treatment; and sintering at 1050°C, 850°C ℃+480℃+280℃ three-stage tempering treatment to prepare sintered NdFeB magnets, the magnetic properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com