Universal chassis for instrumentation

A technology of instrumentation and chassis, which is applied in the field of general instrumentation chassis, can solve the problems of unreasonable material structure of the chassis, difficulty in changing the overall size and shape, and large deviation of the shape of the chassis, etc., to achieve easy mass production capacity, easy size change, The effect of high overall strength coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

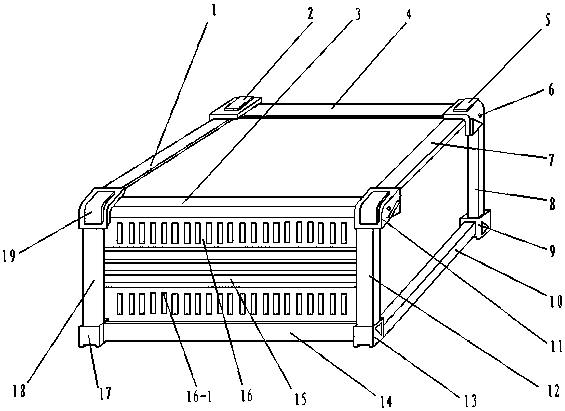

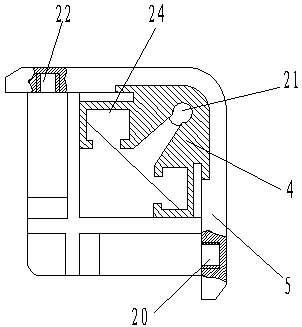

[0018] exist Figure 1~4 Among them, it is a general-purpose chassis for instruments and meters consisting of a front frame, a rear frame, side ribs, side panels, tension ribs, upper and lower covers, and front and rear panels. The upper ends of the left and right columns (12, 8) of the front frame are plugged into The left and right upper corners (11, 5), the lower ends of which are respectively plugged into the left and right lower corners (13, 9) of the front frame, and bolts are screwed into the side rib fixing holes (21) to fix the left and right ribs of the front frame ; The left ends of the upper and lower transverse ribs (7, 10) of the front frame are respectively plugged into the left upper and lower corners (11, 13) of the front frame left column (12), and inserted into the front panel, and the right ends are plugged in respectively In the right upper and lower corners (5, 9) of the front frame right upright column (8), screw the screws into the nuts embedded in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com