Functionally gradient glass cotton felt for high-temperature pipelines

A gradient function, glass wool felt technology, applied in the direction of pipeline protection, pipeline protection through heat insulation, heat preservation, etc., can solve the problems of insufficient maximum temperature resistance of the insulation layer module, high thermal conductivity of insulation materials, affecting the insulation performance of materials, etc., to achieve Prevent heat loss, ensure heat preservation effect, and prevent moisture accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

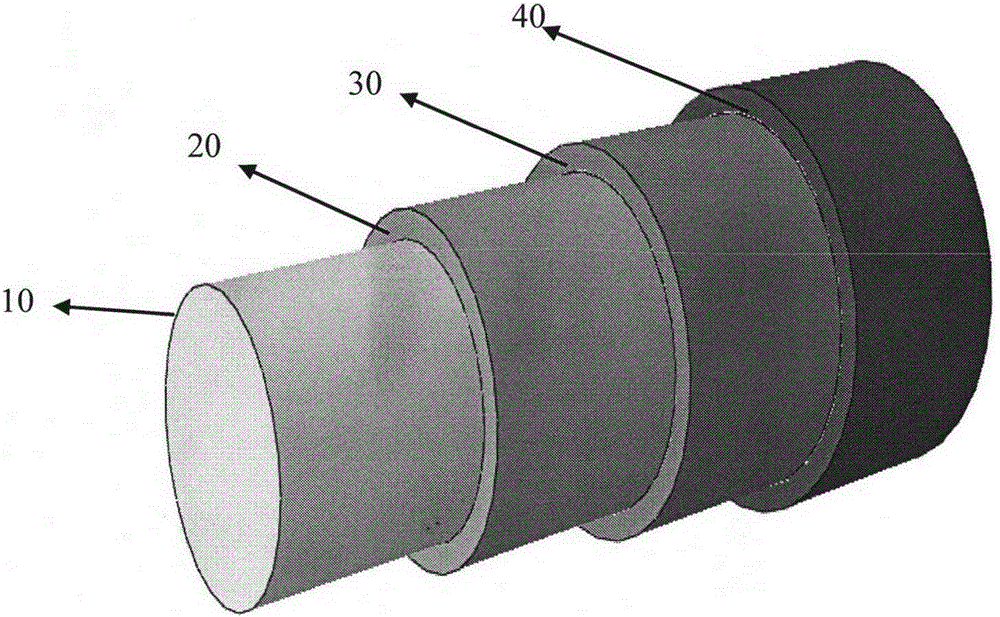

[0016] refer to figure 1 , is a structural diagram of a high-temperature pipeline that uses gradient function glass wool felt for insulation, 10 is the inner working tube, 20 is the ultrafine ceramic fiber paper layer, 30 is the ultrafine glass fiber paper layer, and 40 is the water-repellent and flame-retardant glass The fiber felt is characterized in that the gradient functional glass wool felt is composed of superfine ceramic fiber paper layers with a thickness of 2 mm from the inside to the outside, the thickness of the fiber paper is 5 microns, and zirconium silicate is filled between the paper and the paper , Silicon carbide hollow ceramic powder, the particle size of the powder is 10 nanometers, the wall thickness of the powder is 1 nanometer, and a layer of 1 micron thick stainless steel film is sandwiched every 1 millimeter; the ultrafine glass fiber paper layer with a thickness of 5 millimeters, The thickness of the fiber paper is 2 microns, the airgel is filled betw...

Embodiment 2

[0018] refer to figure 1 , is a structural diagram of a high-temperature pipeline that uses gradient function glass wool felt for insulation, 10 is the inner working tube, 20 is the ultrafine ceramic fiber paper layer, 30 is the ultrafine glass fiber paper layer, and 40 is the water-repellent and flame-retardant glass The fiber felt is characterized in that the gradient functional glass wool felt is successively composed of superfine ceramic fiber paper layers with a thickness of 4 mm from the inside to the outside, the thickness of the fiber paper is 15 microns, and zirconium silicate is filled between the paper and the paper , silicon carbide hollow ceramic powder, the particle size of the powder is 50 nanometers, the wall thickness of the powder is 3 nanometers, and a layer of 3 micron thick stainless steel film is sandwiched every 1 millimeter; the thickness of the ultrafine glass fiber paper layer is 50 millimeters, The thickness of the fiber paper is 10 microns, the airg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com