Liquid piston device with internal temperature control for gas isothermal scaling based on gas storage unit

A liquid piston and gas storage technology, which is applied in the direction of machines/engines, non-volume pumps, mechanical equipment, etc., can solve the problems of large energy loss and achieve the effects of improving efficiency, reducing pollution, and basically stabilizing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments will be described in detail below in conjunction with the accompanying drawings.

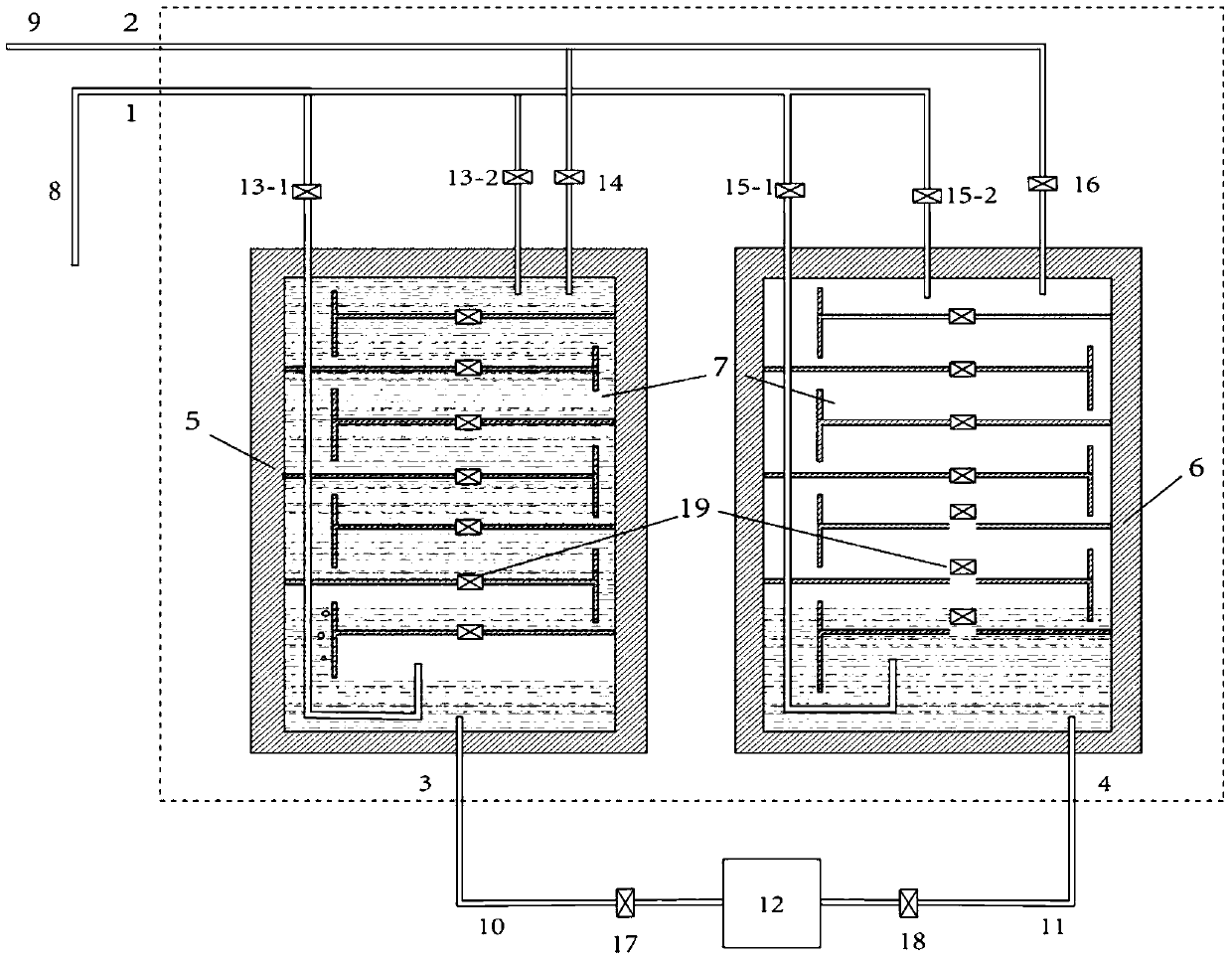

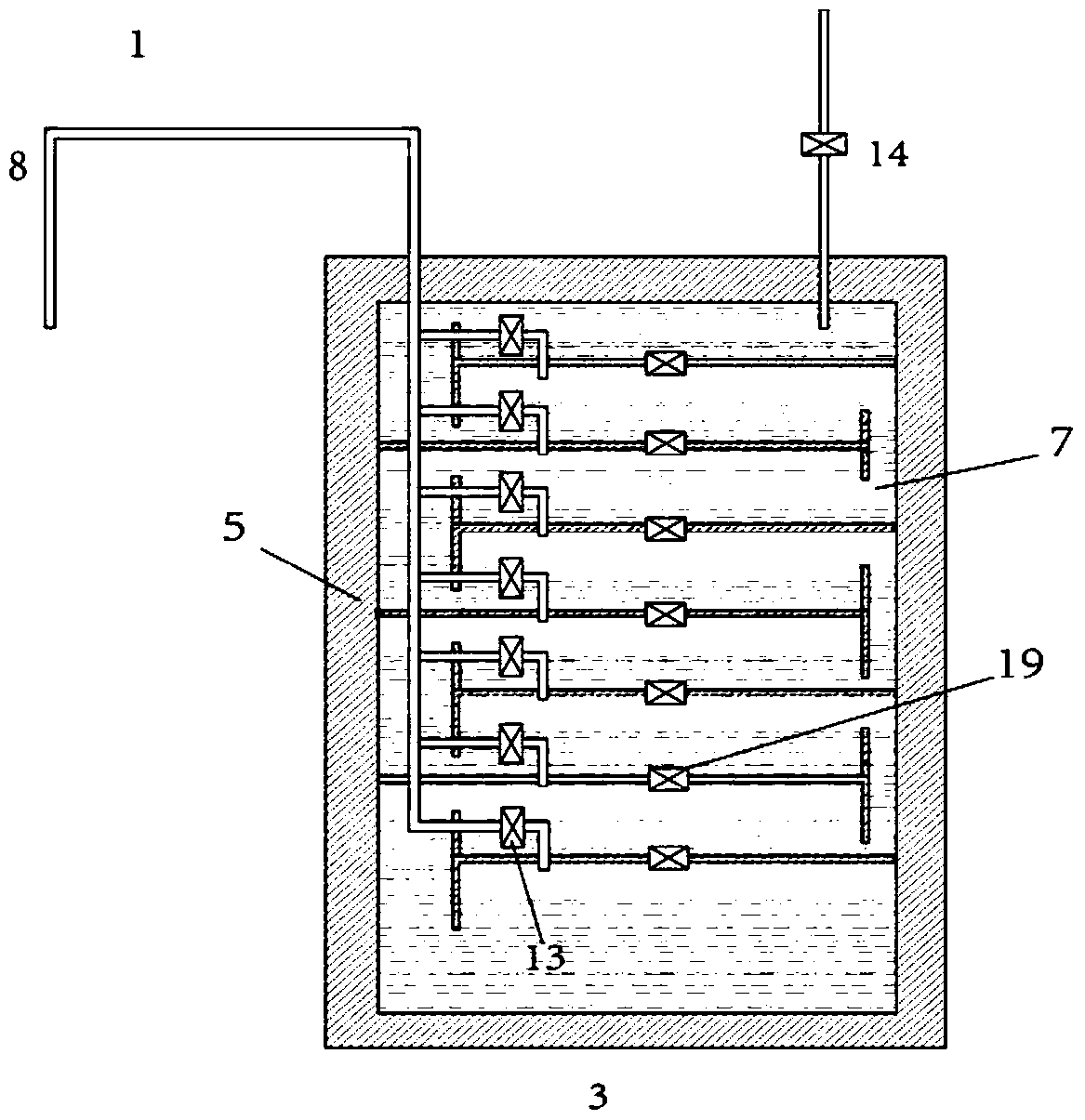

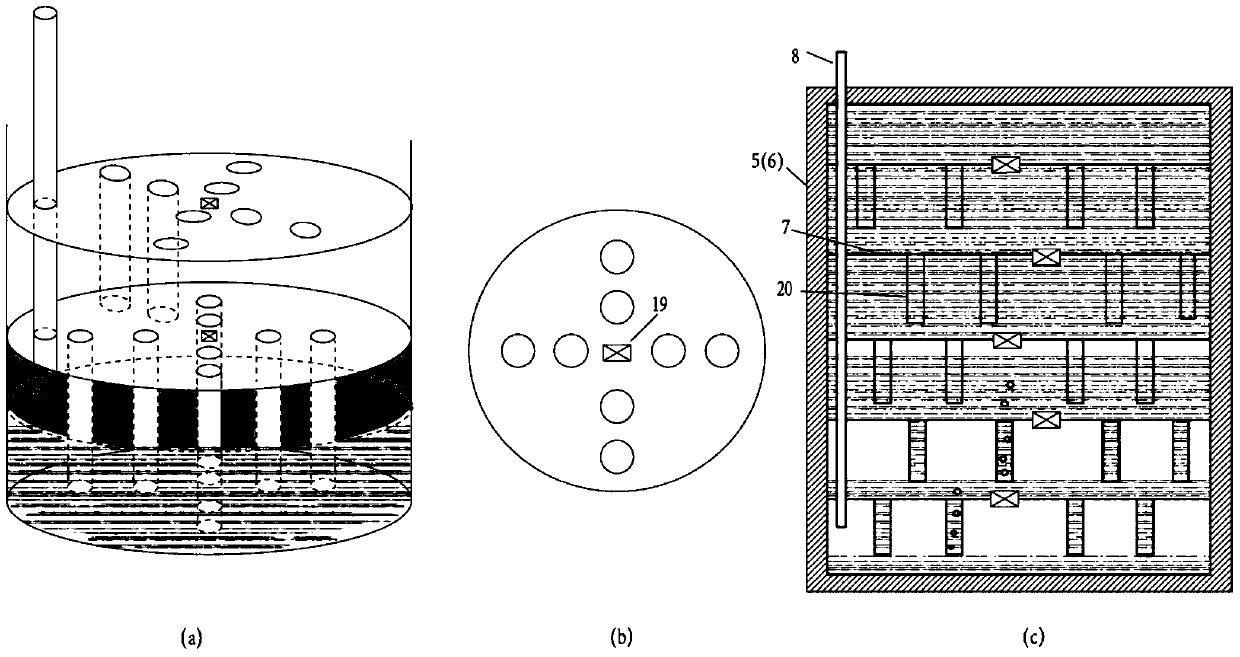

[0032] figure 1 It is a scheme of an internal temperature-controlled liquid piston device that realizes gas isothermal scaling. The device is composed of a first liquid piston chamber 5, a second liquid piston chamber 6, several gas storage units 7 in the chamber, a high-pressure gas pipeline 8, a low-pressure gas pipeline 9, a first liquid pipeline 10, a second liquid pipeline 11, and a gas valve. 13-16, liquid valves 17-18, and the isolation valve 19 of the gas storage unit; wherein the first liquid piston chamber 5 is connected to the high-pressure gas pipeline 8 and the The low-pressure gas pipeline 9 is connected, and the second liquid piston chamber 6 is respectively connected with the high-pressure gas pipeline 8 and the low-pressure gas pipeline 9 through gas valves 15 and 16; multiple chambers are respectively arranged in the first liquid piston chamber 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com