Positioning control system for oxygen lance device

A technology of positioning control and oxygen lance, applied in the direction of manufacturing converters, etc., can solve the problem of low positioning accuracy, and achieve the effect of improving positioning accuracy, ensuring full-process accuracy, and eliminating low positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

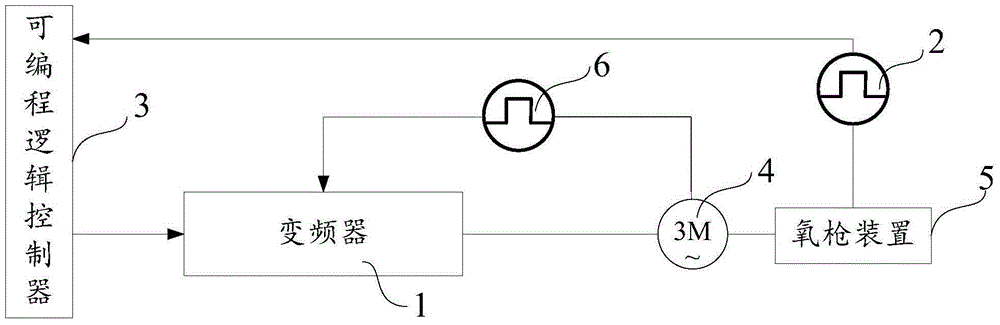

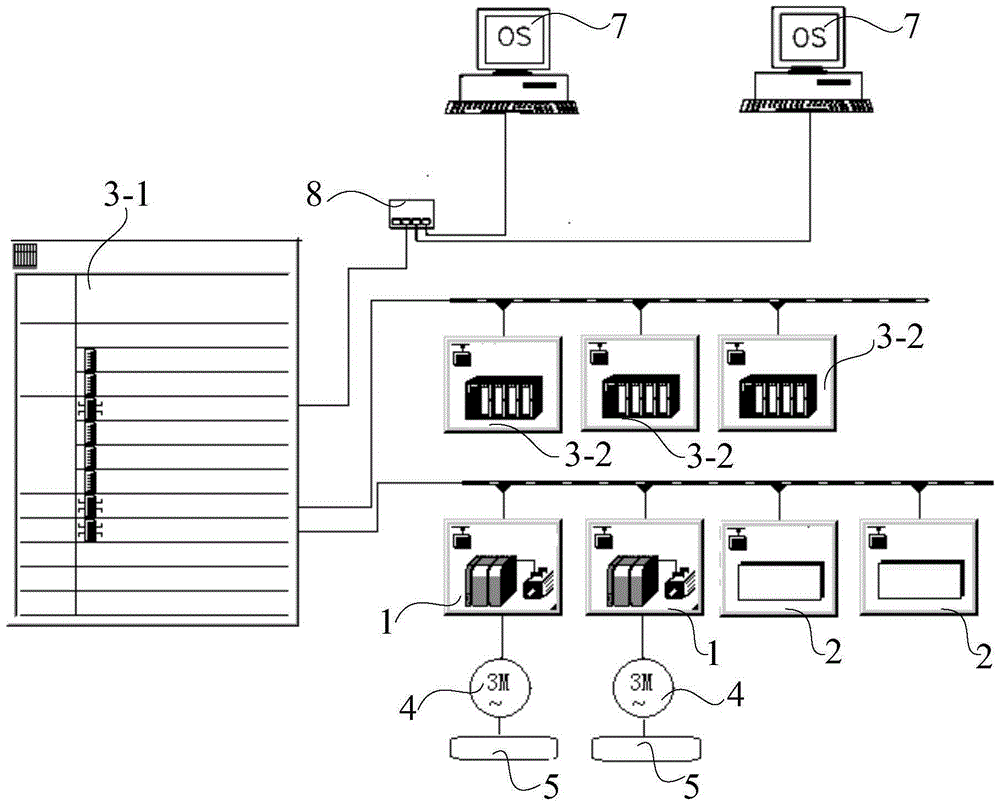

[0026] In order to solve the technical problem of low positioning accuracy of the existing oxygen lance device transmission system when approaching the target position, the embodiment of the present invention provides a positioning control system for the oxygen lance device, the general idea is as follows:

[0027] The real-time detected gun position detection value is sent back to the programmable logic controller through the position encoder. The programmable logic controller sends start-stop command and speed control command to the frequency converter through logic calculation. Then the inverter acts as the driving side to convert the fixed AC power supply into the electric energy with variable frequency and certain torque and transmit it to the oxygen lance motor according to the instructions of the programmable logic controller. The oxygen lance motor drives the oxygen lance device to move, and reaches the gun position corresponding to each gun position setting value in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com