Three-dimensional printing photosensitive resin material containing modified butadiene rubber and preparation method

A photosensitive resin and 3D printing technology, which is applied in the field of photosensitive resin materials for 3D printing, can solve problems such as compatibility and toughness, and achieve the effect of improving compatibility and solving brittleness problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

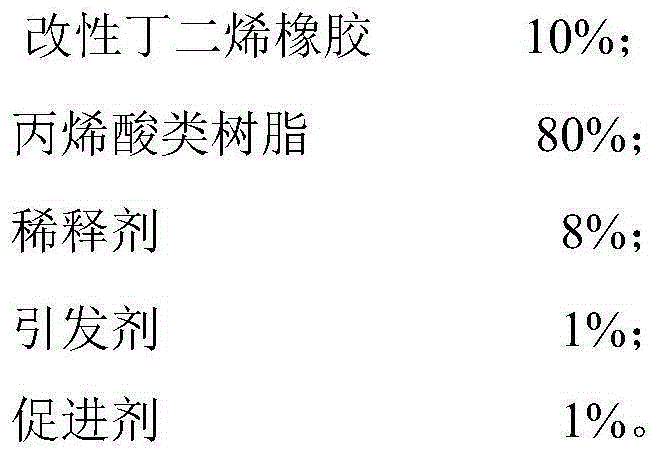

[0028] 1. Proportion according to mass percentage:

[0029]

[0030] 2. Preparation method:

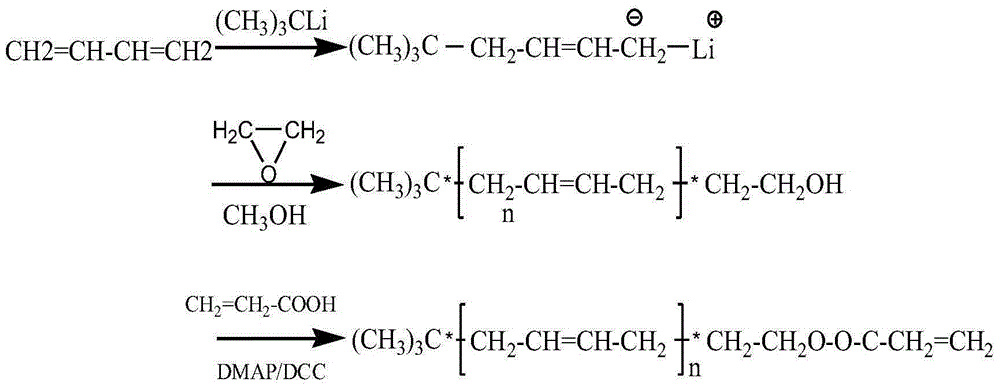

[0031] (1) Preparation of modified butadiene rubber: with (CH 3 ) 3 With CLi as the initiator and cyclohexane as the solvent, butadiene undergoes anionic polymerization and is capped with ethylene oxide and methanol at a temperature of 40-50°C for 1-2 hours to obtain polybutadiene with terminal hydroxyl groups. Diene telechelic polymer with a molecular weight of 1000-10000 is esterified with low-molecular-weight acrylic acid at 120-150°C using triethylenediamine as a catalyst for 8 hours to introduce double bond groups, wherein the mass ratio of the (CH 3 ) 3 CLi: cyclohexane: butadiene: ethylene oxide: methanol = (1-2.5): 30: (1.5-2.5): (1.5-2.5): 1, the polybutadiene telechelic polymer: Acrylic acid: triethylenediamine = 1:1: (0.01-0.05).

[0032] (2) Weigh 40g, 30g, 10g, 8g of acrylic resin, urethane acrylate resin, epoxy acrylate resin and trihydroxyacrylate respectively,...

Embodiment 2

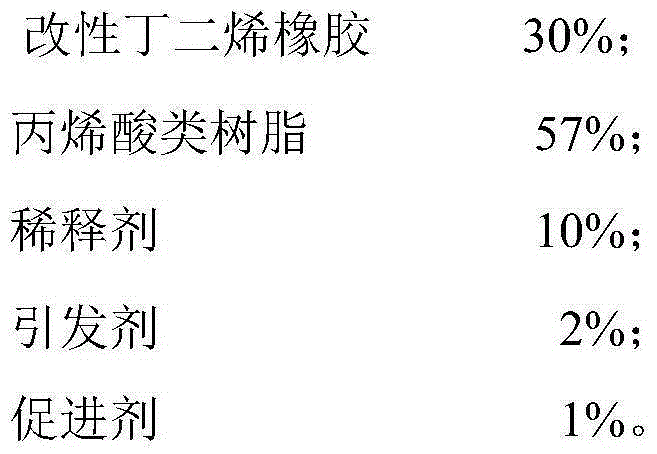

[0037] 1. Proportion according to mass percentage:

[0038]

[0039] 2. Preparation method:

[0040] (1) The preparation of modified butadiene rubber is the same as in Example 1.

[0041] (2) Take by weighing acrylic resin, urethane acrylate resin, epoxy acrylate resin and 1,6-hexanediol diacrylate 20g, 10g, 27g, 10g respectively, and weigh 30g of prepared modified butadiene rubber , weigh 2g of UV-1173 and 1g of phosphate methacrylate, put them into a mixer, set the speed at 300r / min, and take 10-20min to obtain a photosensitive resin material;

[0042] (3) After the photosensitive resin material obtained in step (2) is left to stand for 15 minutes, it is coated on a surface-treated iron sheet, and the iron sheet is placed in a light curing machine for curing. The light curing wavelength is set to 350-400nm, and the light curing machine The conveyor belt speed is 1.5cm / s, and the curing time is 60s.

[0043] Three, the effect of this embodiment:

[0044] A universal te...

Embodiment 3

[0046] 1. Proportion according to mass percentage:

[0047]

[0048]

[0049] 2. Preparation method:

[0050] (1) The preparation of modified butadiene rubber is the same as in Example 1.

[0051](2) Weigh acrylic resin, urethane acrylate resin, epoxy acrylate resin and styrene 10g, 10g, 10g, 40g respectively, weigh 26g of prepared modified butadiene rubber, weigh 2g2,2-diene Methoxy-2-phenylacetophenone and 2g methacrylic acid phosphate, put into the mixer and stir, set the speed at 300r / min, the time is 10-20min, let it stand for 15min and coat it on the surface-treated iron sheet, Place the iron sheet in the light curing machine for curing, set the light curing wavelength to 350-400nm, the speed of the light curing machine conveyor belt to 1.5cm / s, and the curing time to 30s.

[0052] 3. The effect of this embodiment: the mechanical properties of the composite resin were tested by a universal testing machine, the impact strength was 374J / M, the tensile strength was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com