Stepped horizontal subsurface flow constructed wetland combined system and application thereof

A horizontal subsurface flow and artificial wetland technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of high construction cost, flat bottom of wetland, and many dead water areas. Achieve the effect of expanding application range, simple construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

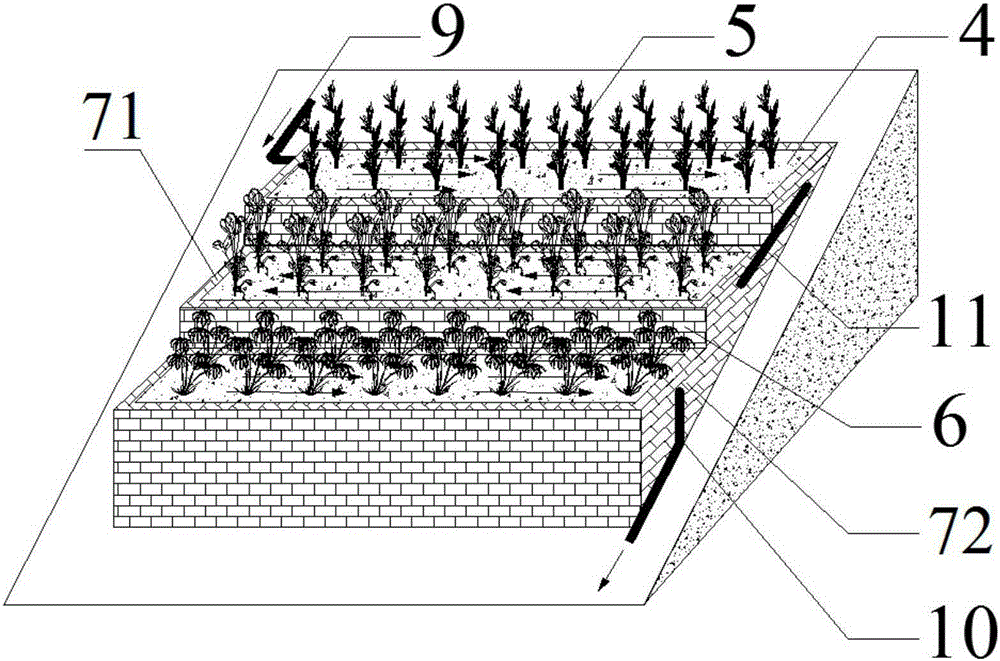

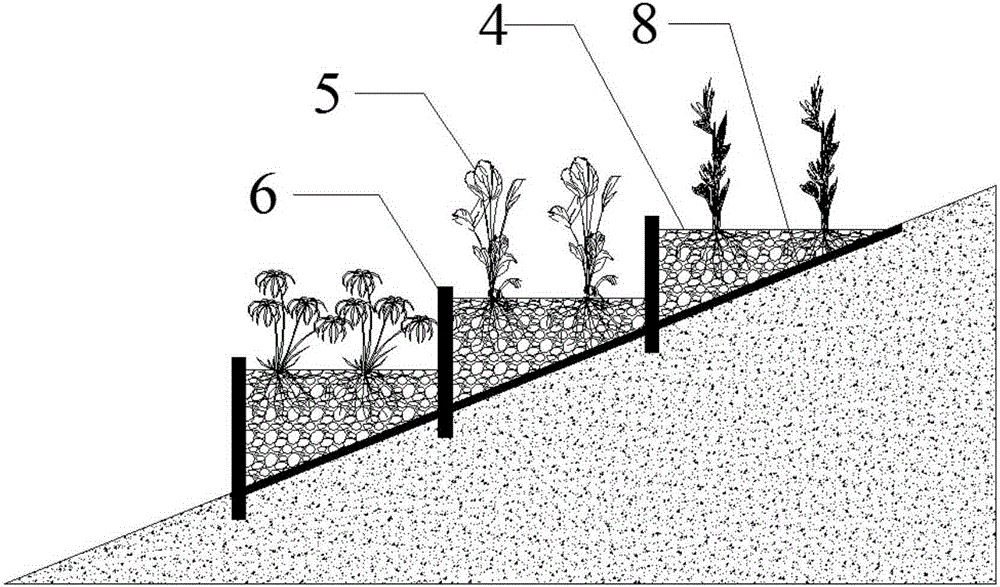

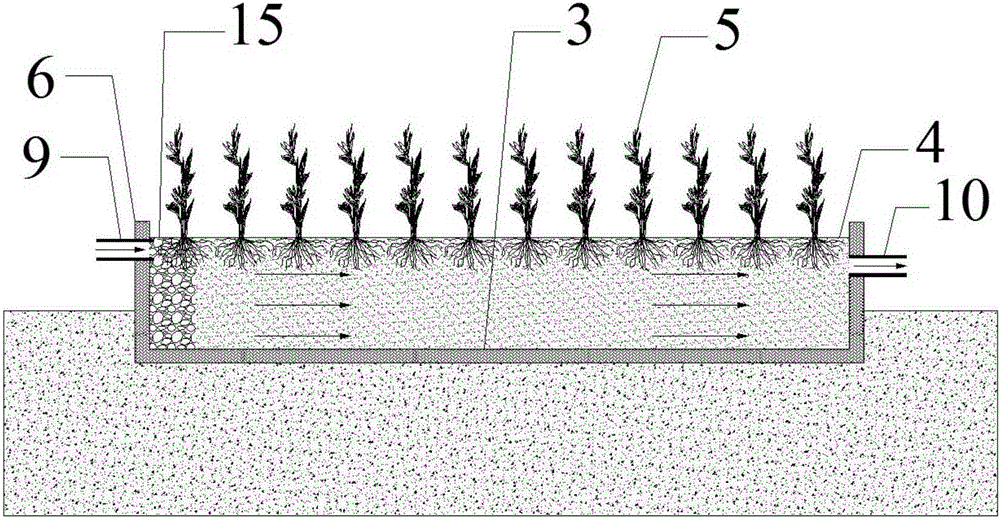

[0052] In this embodiment, a stepped horizontal subsurface flow constructed wetland combination system, such as figure 1 , figure 2 , image 3 As shown, it consists of three levels of rectangular horizontal subsurface flow constructed wetland units 1 and pipe network units 2 that are distributed stepwise from top to bottom according to the slope, and the horizontal subsurface flow constructed wetland units 1 are connected in series. The horizontal subsurface flow constructed wetland unit 1 is composed of a pool body 3 , a matrix 4 and plants 5 . The pool body 3 is composed of the outer wall 6 of the upper and lower level subsurface flow constructed wetland unit 1 , the water inlet retaining wall 71 , the water outlet retaining wall 72 and the pool bottom 8 . The pipe network unit is composed of a water inlet pipe 9, an outlet pipe 10 and a connecting pipe 11 connecting the upper and lower level subsurface flow constructed wetland units 1.

[0053] The system is applied to ...

Embodiment 2

[0061] In this embodiment, a stepped horizontal subsurface flow constructed wetland combination system, such as Figure 5 with Image 6 As shown, it consists of four levels of rectangular horizontal subsurface flow constructed wetland units 1 and pipe network units 2 that are distributed stepwise from top to bottom according to the slope, and the horizontal subsurface flow constructed wetland units 1 are connected in parallel.

[0062] The system is used for the purification treatment of the tail water of the sewage treatment plant in a certain urban river, which uses the tail water of the sewage treatment plant as supplementary water. The constructed wetland system is located on a plane slope near the tailwater outlet, with a slope angle of about 25° and a slope length of about 40m. The artificial wetland treatment system covers an area of 260 square meters, and the designed treatment capacity is 100 tons per day. The influent water quality of the wetland design is Class ...

Embodiment 3

[0068] In this embodiment, a stepped horizontal subsurface flow constructed wetland combination system, such as Figure 7 As shown, it consists of four levels of horizontal subsurface flow constructed wetland unit 1 and pipe network unit 2 that are distributed stepwise from top to bottom according to the slope. The horizontal subsurface flow constructed wetland units are connected in parallel, and the pool body is built into a long strip according to the mountain situation.

[0069] The system is used for domestic sewage treatment in a rural residential area. The constructed wetland treatment system is located on the hillside under the sewage outfall, with a slope angle of about 22°. The constructed wetland treatment system covers an area of 360 square meters. It is composed of four rectangular horizontal subsurface flow constructed wetland units 1 with an area of 30m×3m connected in parallel. The designed treatment capacity is 120 tons per day.

[0070]The pipe network ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com